A composite ignition circuit

An ignition circuit and composite technology, which is applied in the professional field of aerospace propulsion technology, can solve the problems of semiconductor spark plug end surface pollution, output voltage easy to jitter, high-voltage switch selection difficulties, etc., to ensure ignition reliability and reduce end area pollution , The effect of suppressing the secondary voltage oscillation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0028] The invention provides a composite ignition circuit, which has the advantages of large ignition energy, no need for a high-voltage switch, no pollution accumulation, and long service life of an external spark plug.

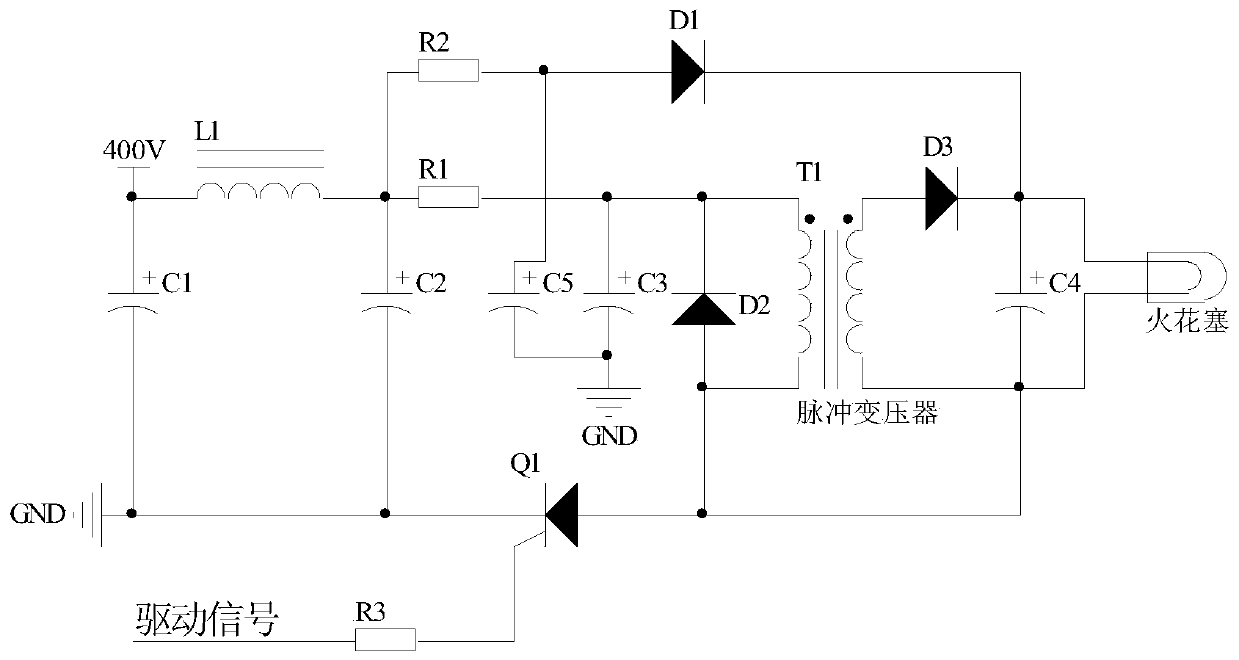

[0029] Such as figure 1 Shown is a schematic diagram of a composite ignition circuit. As can be seen from the figure, a composite ignition circuit includes a first resistor R1, a second resistor R2, a third resistor R3, a first capacitor C1, a second capacitor C2, and a third capacitor C3 , the fourth capacitor C4, the fifth capacitor C5, the first diode D1, the second diode D2, the third diode D3, the inductor L1, the transformer T1 and the MOS transistor Q1;

[0030] Wherein, one end of the first capacitor C1 is connected to an external power supply, and the other end of the first capacitor C1 is grounded; one end of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com