A standardized modular unit of direct-fired linear burner with high turndown ratio

A modular unit and adjustment ratio technology, which is applied to gas fuel burners, burners, combustion methods, etc., can solve the problems of limited application, poor ignition stability, and heat utilization, and achieve the purpose of suppressing nitrogen oxides (NOx) The generation, ensuring the reliability and safety of work, reducing the effect of heat spread and heat radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the accompanying drawings and typical embodiments.

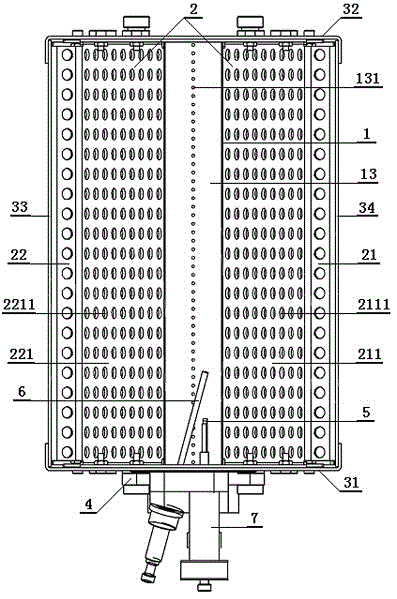

[0050] exist figure 1 Among them, the standardized module unit main body of the high adjustment ratio direct-fired linear burner of the present invention includes a gas nozzle 1, a porous air intake wing plate 2, a baffle plate 3, a fixed end plate 4, an ignition needle 5, a flame detector 6 and a flame The observation mirror 7 is characterized in that: the porous air intake vane 2 includes a left air intake vane 21 and a right air intake vane 22, and the baffle plate 3 includes a front end baffle 31, a rear end baffle Plate 32, left side baffle 33, right side baffle 34, wherein:

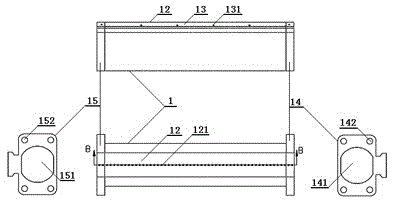

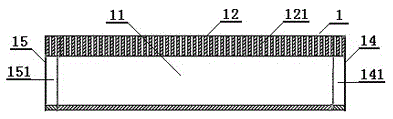

[0051] exist figure 2 and image 3 Among them, the main body of the gas nozzle 1 is in the shape of a hollow long cylinder, and the main working panel A12 with a number of gas injection holes 121 arranged in an orderly manner is arranged on the left and right side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com