Heat pipe vacuum liquid filling and degassing method and equipment adopting same

A technology for degassing equipment and heat pipes, which is applied in the field of heat pipe vacuum liquid filling and degassing methods and equipment, can solve the problems of wasting metal materials, loss of working fluid, etc., and achieve high production efficiency, high precision, and simple and easy technical means Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

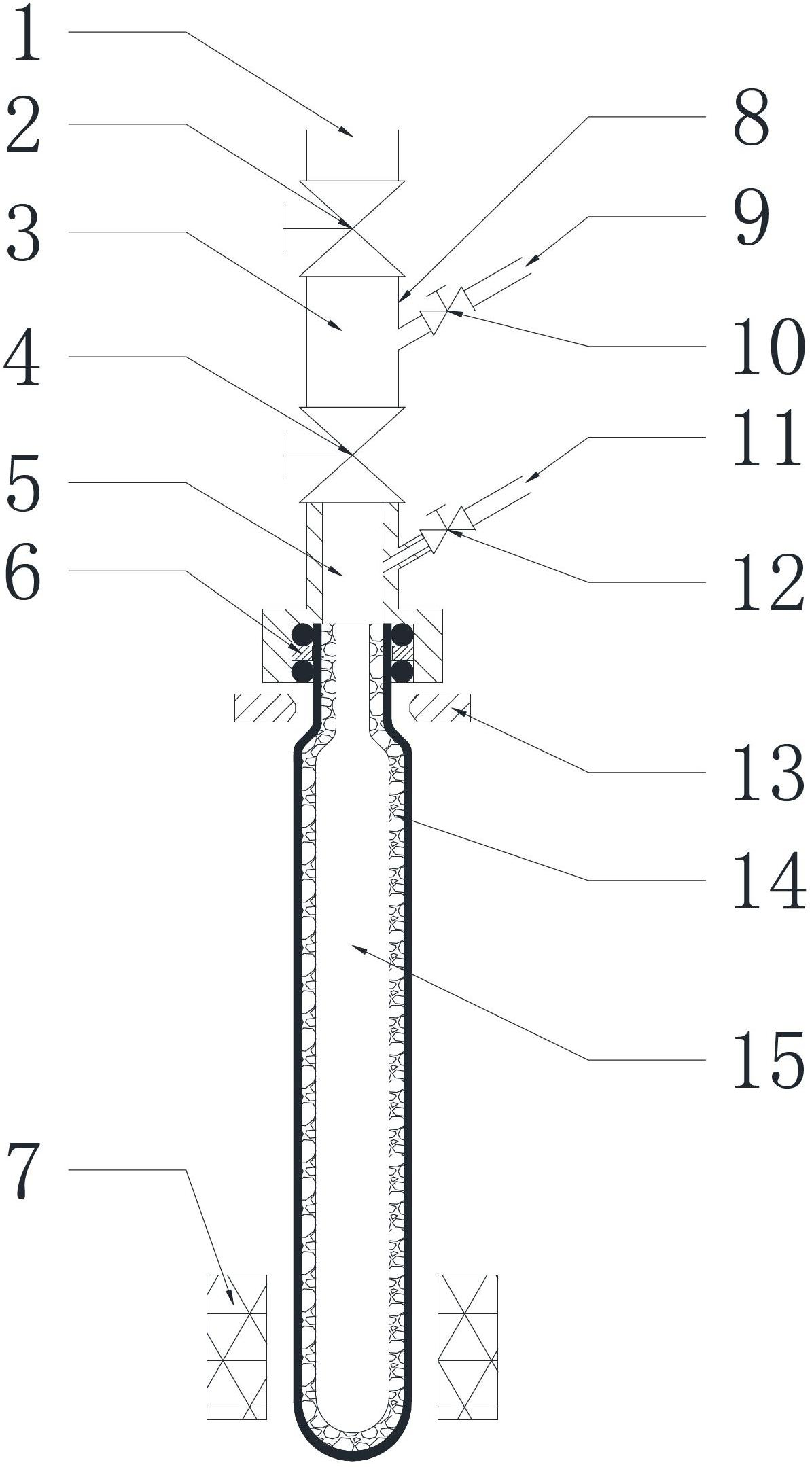

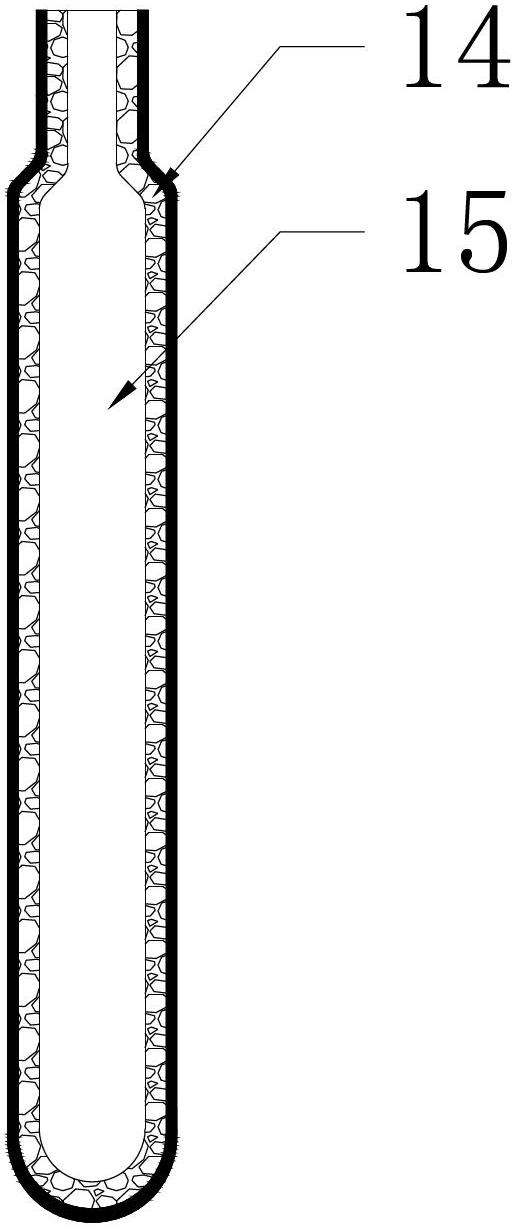

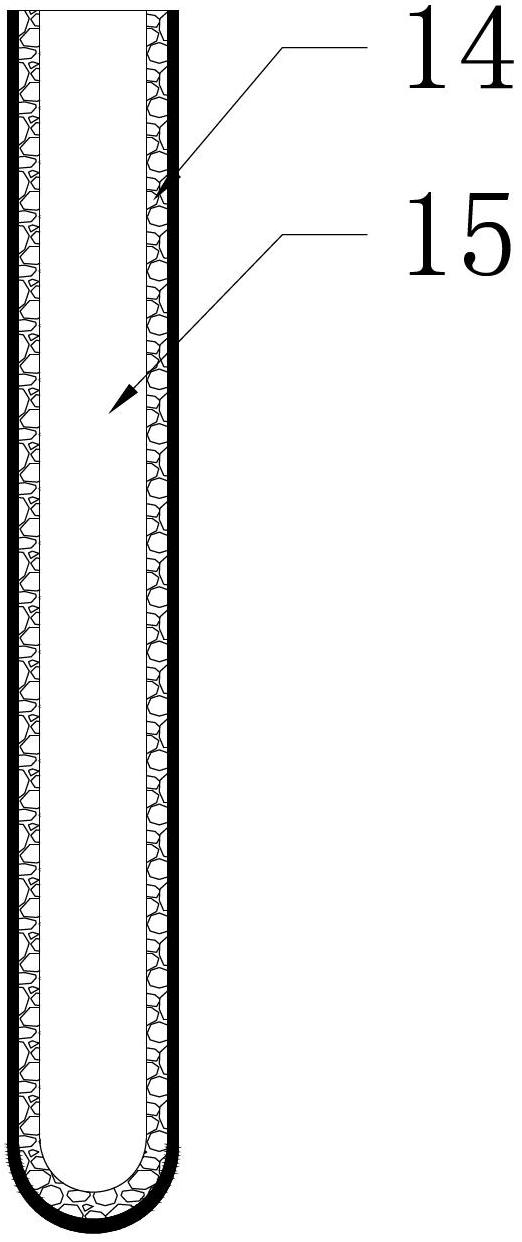

[0020] Such as figure 1 shown. The heat pipe vacuum filling and degassing equipment of the present invention includes a vacuum system 1, a perfusion system 11, an action pipeline 8, a heating module 7 and a sealing mold 13. An electromagnetic valve 4 is arranged in the middle of the action pipeline 8, and the action pipeline 8 is covered by the electromagnetic valve. The valve 4 is divided into upper chamber 3 and lower chamber 5. The vacuum system 1 is connected to the upper chamber 3 of the action pipe 8 by a vacuum solenoid valve 2. The perfusion system 11 is connected to the lower chamber 5 of the action pipe 8 by a needle valve 12. The sealing mold 13 is arranged on the nozzle side of the heat pipe 15 to be processed, and the heating module 7 is arranged at the tail of the heat pipe 15 to be processed.

[0021] The upper chamber 3 is connected with an air source 9 and is provided with a shut-off valve 10 for controlling its on-off.

[0022] The lower cavity 5 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com