Inertia fiber filter membrane device for grading particles

A fiber filter membrane and inertial technology, applied in the direction of sampling devices, etc., can solve the problems of difficult to accurately detect air quality or pollution index, the classification and collection of particulate matter is not accurate and stable, and difficult to collect particulate matter, so as to facilitate the collection of particulate matter and benefit Collision collection, good collection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

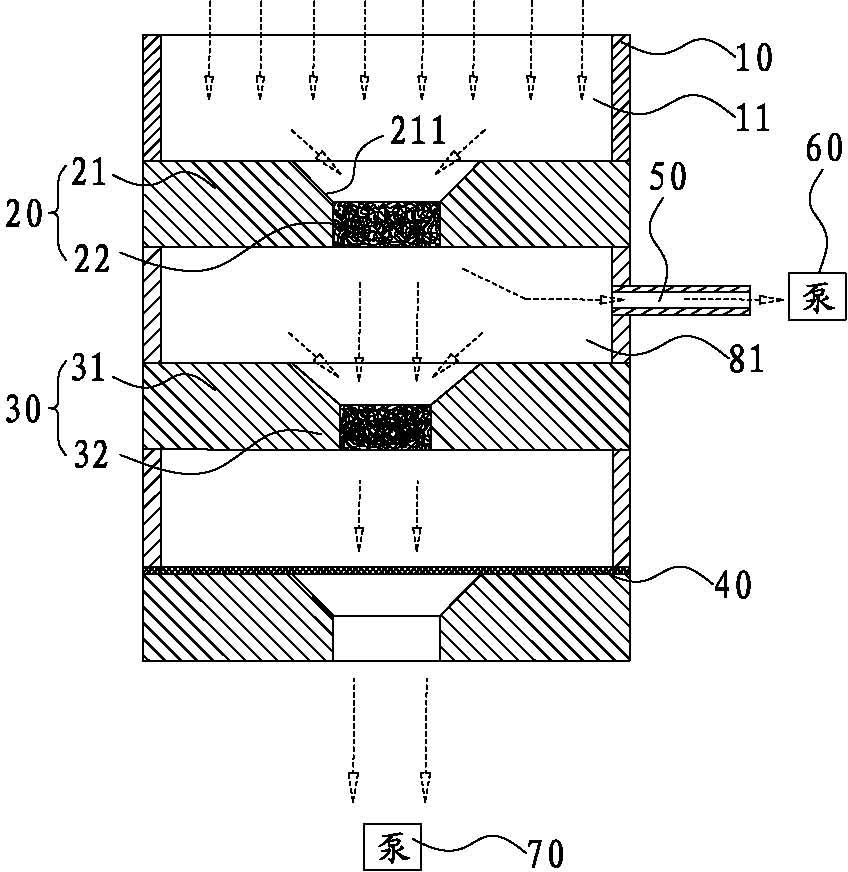

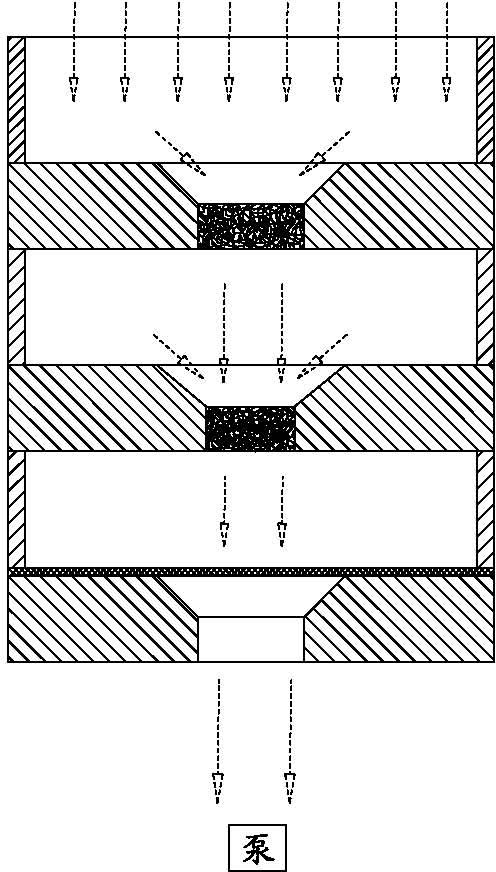

[0036] Please refer to Figure 1 to Figure 6 As shown, it shows the specific structure of the preferred embodiment of the present invention, which includes a housing 10, a multi-stage impact collection group and a suction pump 70, and the suction pump 70 (usually a suction pump) is arranged in the housing At the air outlet of the body 10, in order to form a continuous and stable airflow from the air inlet to the air outlet.

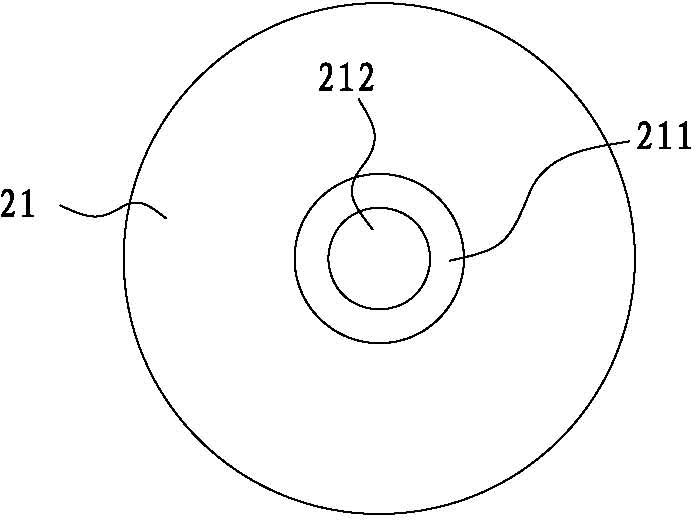

[0037] The housing 10 is hollow, and a sampling channel 11 extending up and down is formed inside it, and an air inlet and an air outlet are respectively provided on the housing along the two ends of the sampling channel 11, and are arranged in sequence along the airflow direction in the sampling channel 11. There is a first collision collection group 20, a second collision collection group 30 and a third collision collection group 40. Of course, the series setting of the collision collection group is not limited to this, and it can be set according to ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com