Vacuum self-electricity-consumption arc furnace molten drop test method based on a silicon-controlled power supply

A technology of vacuum consumable arc and test method, which is applied in measuring devices, measuring electrical variables, measuring pulse characteristics, etc., can solve the problems of high import price and non-sale, and achieve quality assurance, arc length assurance, and compactness assurance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0025] Specific embodiment: adopt 3t vacuum self-consumption electric arc furnace to smelt tungsten-manganese alloy steel, the furnace pressure reference value is 24V, and the output base frequency of thyristor power supply is 300Hz. According to the present invention, its steps are as follows:

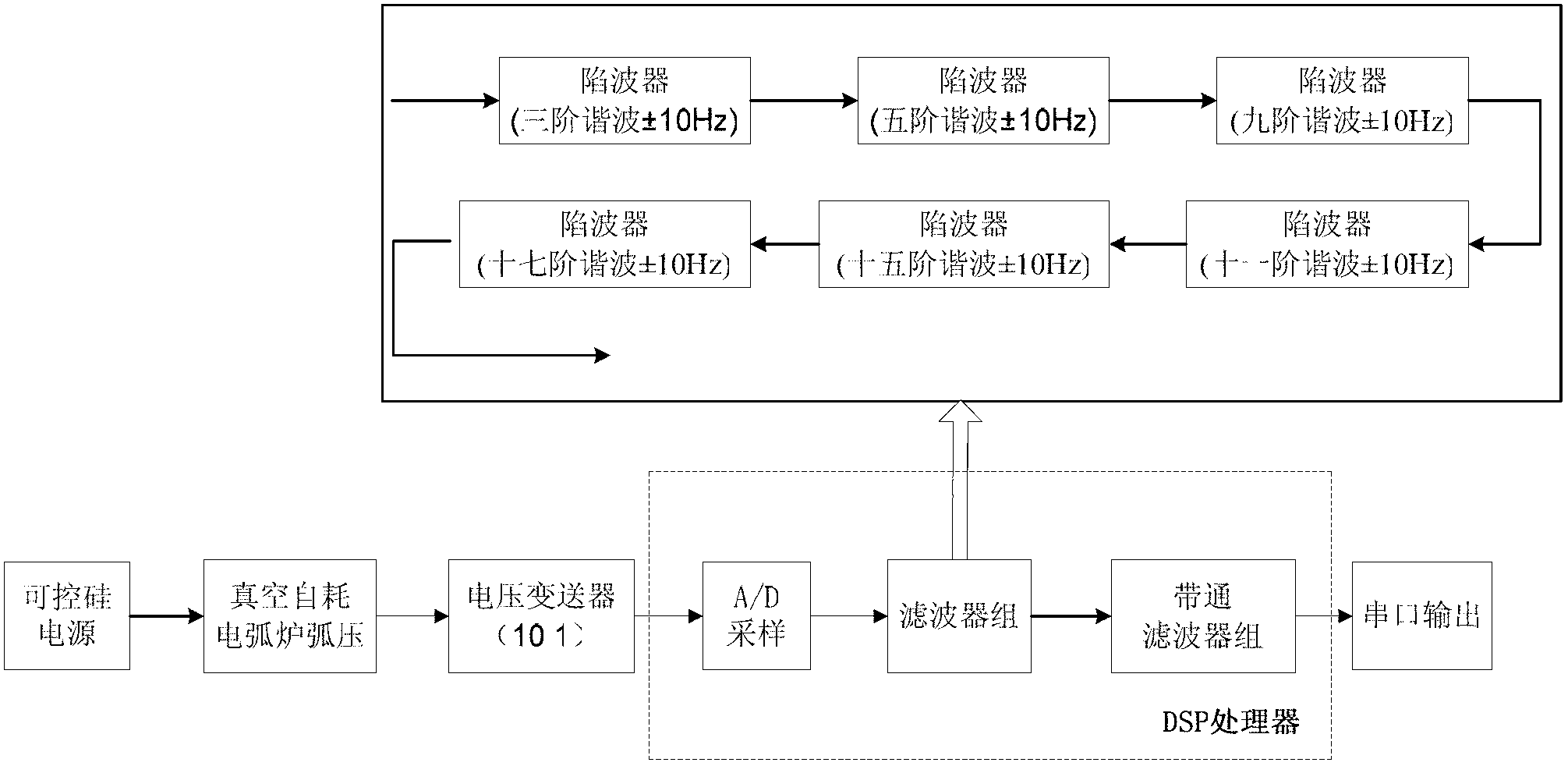

[0026] Step 1: Transform the furnace pressure signal output by the thyristor power supply to 0-3V after 10:1 transformation, send it to the DSP processor for high-speed sampling with a frequency of 50KHz, and store the digital signal after the sampling conversion is completed In the ping-pong buffer, the size of each area is 25K, each storing half a second of data.

[0027] Step 2: While sampling, process the data in the ping-pong buffer in real time. Take half a second of data in the ping-pong buffer as a group, and perform third-order (900Hz), fifth-order (1500Hz), ninth-order (2700Hz), and eleventh-order (3300Hz) sampling data for the thyristor power supply used. , 15th order (450...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com