Method for manufacturing surface acoustic wave transducer sensitive membrane

A technology of surface acoustic wave and sensitive film, which is applied in the direction of using sound wave/ultrasonic wave/infrasonic wave to analyze fluid, vacuum evaporation plating, coating, etc. It can solve the problems of low applicable value, high working temperature, and low selectivity of sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

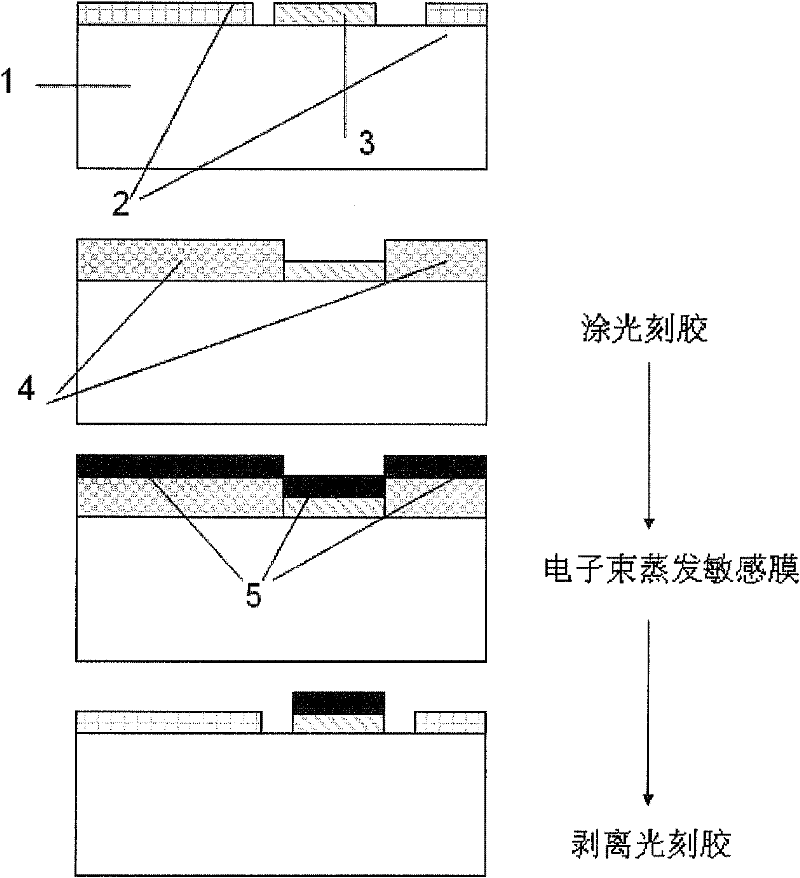

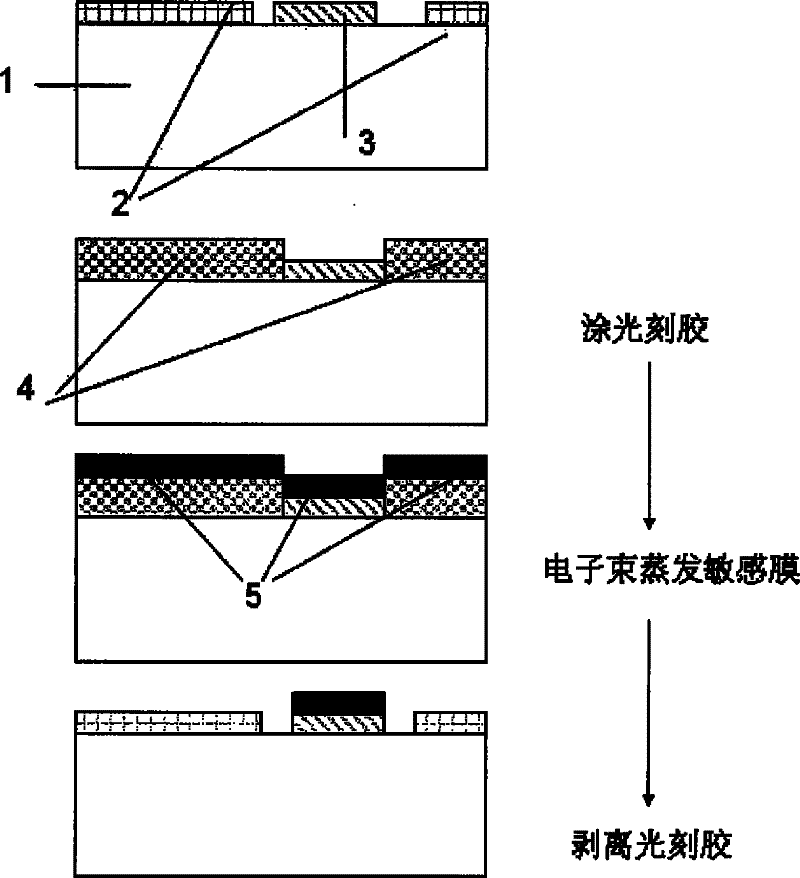

[0030] The production provided by the embodiment of the present invention is used to detect NO 2 The method of the sensitive film of the surface acoustic wave sensor of the gas is to use about 1g of WO with a mass ratio of 1:1 3 with TiO 2 Mix according to the material, and then machine TiO 2 and WO 3 The mixed material is pressed into a block, and then the photoresist is coated on the substrate, and the block TiO 2 and WO 3 The mixed material is evaporated as the target material for electron beam evaporation, and a film of about 50nm-200nm is deposited on the substrate coated with photoresist, and then the substrate is soaked in acetone or ethanol solution to peel off the photoresist, and then vacuum dried at room temperature form a sensitive film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com