Intelligent defect screening and sampling method

A defect and intelligent technology, applied in the field of defect analysis, can solve the problems of limited number, omission to identify fatal defects, limited time of the foundry, etc., to achieve the effect of increasing the detection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example 〕

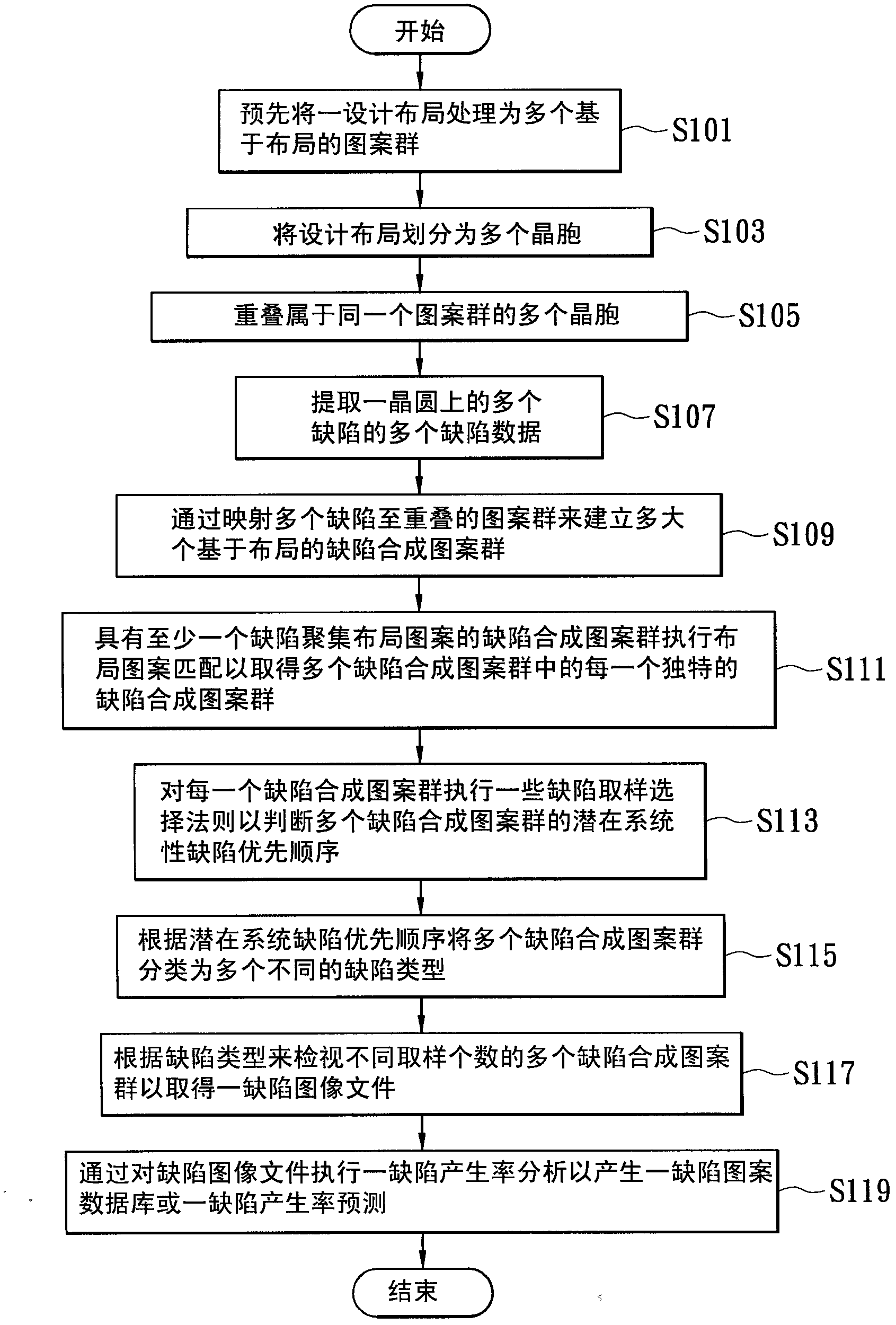

[0036] Next, please refer to Figure 1B , Figure 1B It is a flow chart of the first embodiment of the intelligent defect screening and sampling method of the present invention.

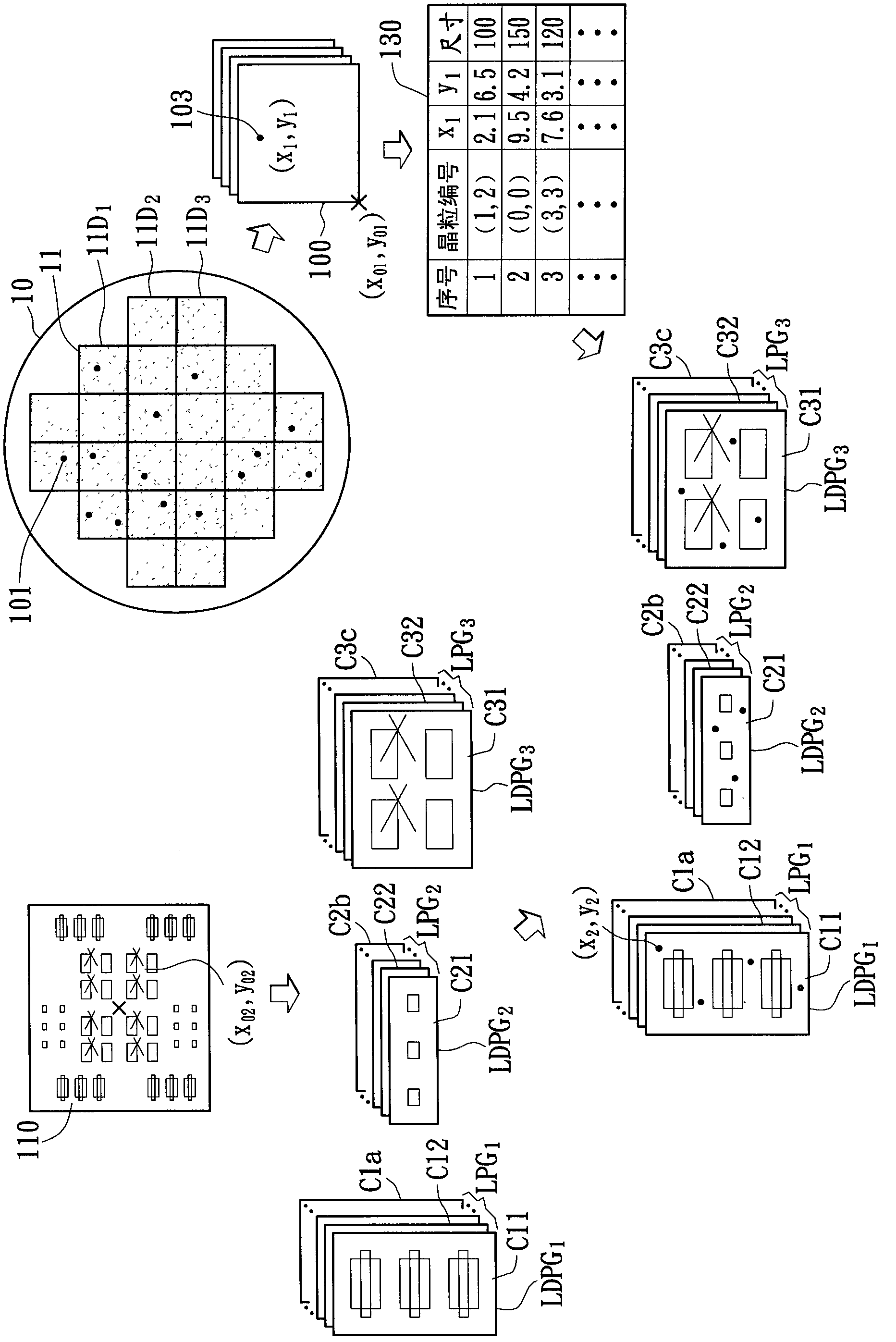

[0037] Please also refer to Figure 1C , Figure 1C It is a schematic diagram of the first embodiment of the intelligent defect screening and sampling method of the present invention.

[0038] The user pre-processes the design layout 110 into a plurality of layout based pattern group (layout based pattern group) LPG 1 、LPG 2 、LPG 3 (S101), wherein the design layout 110 is designed by the user for the wafer 10, the wafer 10 has a full-chip layout (full-chip layout) 11, and the full-chip layout 11 includes a plurality of dies (die) 11D 1 , 11D 2 ,, 11D 3 , extract a plurality of dies 11D from a design layout database by computer 1 , 11D 2 ,, and 11D 3 design layout 110, the extracted design layout 110 has a plurality of layout patterns (layout pattern) and a second reference origin (x O2 ,y...

no. 2 example

[0053] Please refer to figure 2 , figure 2 It is a flow chart of the second embodiment of the intelligent defect screening and sampling method of the present invention. Such as figure 2 As shown, the intelligent defect screening and sampling method of the second embodiment is roughly the same as the intelligent defect screening and sampling method of the first embodiment, the difference is that the computer establishes a plurality of layout-based defect synthesis pattern groups LDPG 1 、LDPG 2 、LDPG 3 After ( S109 ), the intelligent defect screening and sampling method of the second embodiment further includes the following steps.

[0054] The computer-implemented defect sampling selection algorithm consists of calculating the LDPG for each defect composite pattern group 1 、LDPG 2 or LDPG 3 A hit rate (S211). where the hit rate is about each defect synthetic pattern group LDPG 1 、LDPG 2 or LDPG 3 The relationship between the number of multiple defects 101 and the ...

no. 3 example

[0065] Please refer to image 3 , image 3 It is a flow chart of the third embodiment of the intelligent defect screening and sampling method of the present invention. Such as image 3 As shown, the intelligent defect screening and sampling method of the third embodiment is roughly the same as the intelligent defect screening and sampling method of the first embodiment, the difference is that after the computer generates a defect pattern database or a defect generation rate prediction (S119) , The intelligent defect screening and sampling method of the third embodiment further includes the following steps.

[0066] The design company 30 downloads the defect pattern database from the website of the factory 20 (S321). The user of the design company 30 extracts a new design layout from a design layout database (S323). Pattern matching is performed on a plurality of new design layout patterns of the new design layout and a plurality of layout patterns in the defect database by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com