Large-sensitization area CMOS image sensor pixel structure and generation method thereof

An image sensor and pixel structure technology, applied in the field of pixel structure, can solve the problems of reducing long-wavelength light quantum efficiency, reducing pixel well capacity, etc., and achieve the effects of reducing image noise, increasing injection concentration, and improving well capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

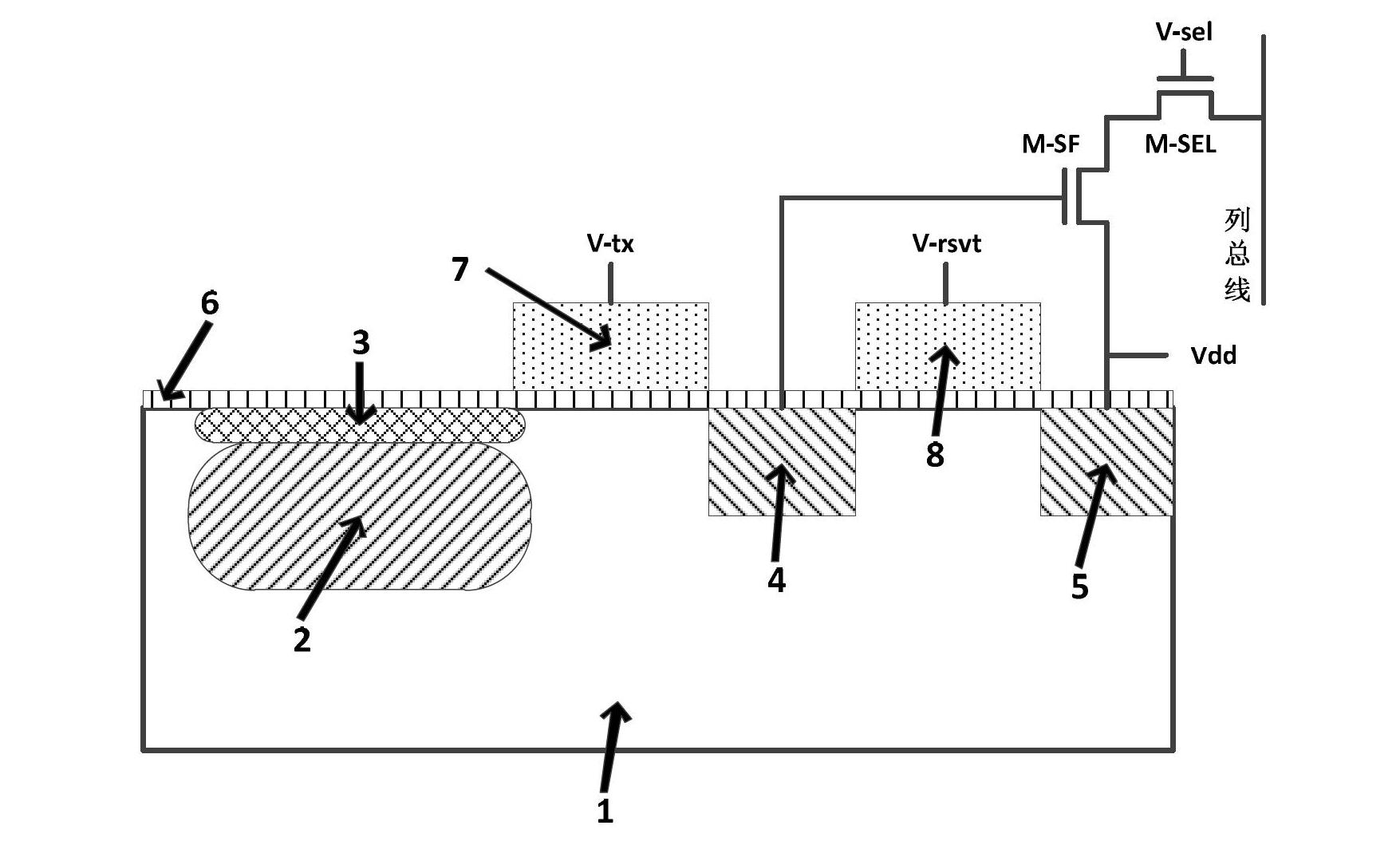

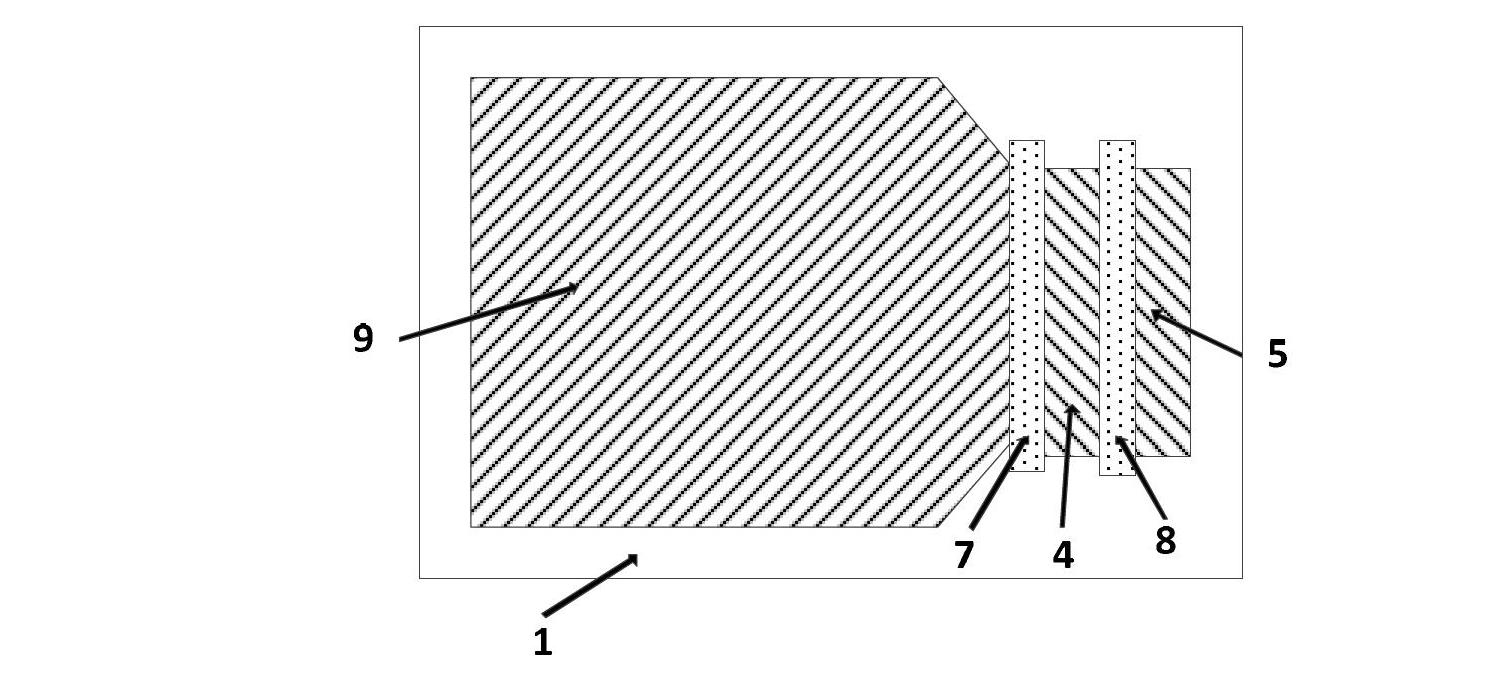

[0023] The technical solution adopted by the present invention is that the pixel structure of the CMOS image sensor with a large photosensitive area is composed of a transmission tube TX, a reset tube RST, a source follower SF, a selection tube SEL, a clamp diode PPD and a storage node FD, and the clamp diode PPD is The N region of the clamp diode and the P region of the clamp diode are arranged on the P-type impurity substrate, and a new P-type impurity injection region is arranged between the N region of the clamp diode and the P region of the clamp diode. The ratio of the area of the overlapping portion of the impurity injection region and the photosensitive region of the clamp diode to the area of the photosensitive region is between 1:100 and 1:5; the shortest distance between the overlapping portion and the TX gate of the transmission tube is greater than 2um; the new P-type impurity The implantation depth of the peak concentration of the implantation region is within...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com