Method for decreasing pH value of ternary material

A ternary material, PH value technology, applied in electrical components, battery electrodes, circuits, etc., can solve problems such as reducing the PH value of ternary materials, and achieve the effect of reducing PH value, environmental friendliness and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

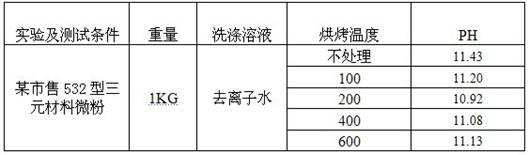

Embodiment 1

[0016] A kind of method of reducing certain commercially available 532 type of the present invention (number of atoms of nickel-cobalt-manganese is, nickel: cobalt: manganese=5:2:3) ternary material micropowder pH value method, comprises the following steps:

[0017] (1) Weigh a commercially available 532 type ternary material micropowder (850 <12), wash with deionized water, the ratio of water to material is 2:1. After washing, filter with suction.

[0018] (2) The material obtained in step (1) is placed in the muffle furnace body for segmental sintering, and the temperature is raised to 85° C. at a heating rate of 50° C. / h, and kept for 8 hours.

[0019] (3) Then raise the temperature to 100-600°C at a heating rate of 50°C / h, and keep it warm for 8 hours, and the preferred temperature is 200°C.

[0020] (iv) After the sintering is completed, the material is taken out, and the particle size distribution range of ball milling is 850 <12 powder.

[0021] The pH value of gaine...

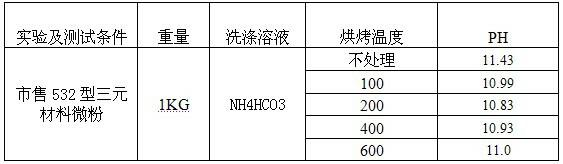

Embodiment 2

[0025] A kind of method of reducing certain commercially available 532 type of the present invention (number of atoms of nickel-cobalt-manganese is, nickel: cobalt: manganese=5:2:3) ternary material micropowder pH value method, comprises the following steps:

[0026] (1) Weigh a commercially available 532 type ternary material micropowder (850 4 HCO 3 solution for washing, control NH 4 HCO 3 The pH value of the solution = 11.0, NH 4 HCO 3 The ratio of solution and material is 2:1. After washing, filter with suction.

[0027] (2) The material obtained in step (1) is placed in the muffle furnace body for segmental sintering, and the temperature is raised to 85° C. at a heating rate of 50° C. / h, and kept for 8 hours.

[0028] (3) Then raise the temperature to 100-600°C at a heating rate of 50°C / h, and keep it warm for 8 hours, and the preferred temperature is 200°C.

[0029] (iv) After the sintering is completed, the material is taken out, and the particle size distribution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com