Current control method for active power filter

A power filter, current control technology, applied in active power filter, harmonic reduction device, AC network to reduce harmonic/ripple and other directions, can solve the problems of slow response, large switching frequency fluctuation, low precision and so on , to achieve the effect of small current following error range, fast dynamic response speed and good filtering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

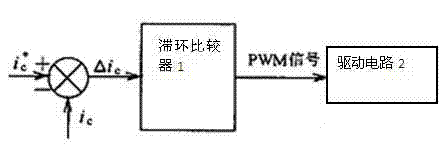

[0026] figure 1 To take the control of one phase as an example, the schematic diagram of the instantaneous value comparison method of the hysteresis comparator 1 is used. In this method, the command signal ic of the compensation current is * Compared with the actual compensation current signal ic, the deviation △ic between the two is used as the input of the hysteresis comparator 1, and the hysteresis comparator 1 generates a PWM signal to control the on-off of the main circuit, and the PWM signal is transmitted by the drive circuit 2 Control the on and off of the switch, thereby controlling the change of the compensation current ic.

Embodiment 2

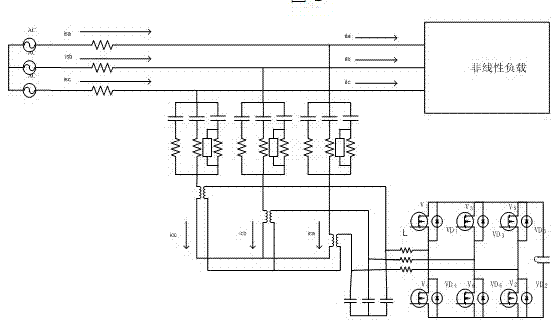

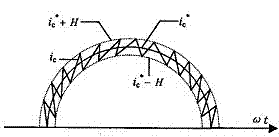

[0028] Let's take phase a as an example for further discussion, let the direction of ic be as follows figure 2 Shown; When the V1 device (IGBT or diode) is turned on, ic will decrease; and when the V4 device is turned on, ic will increase. Use H to represent the bandwidth of the hysteresis comparator 1, the working principle of the hysteresis comparator 1 is as follows image 3 As shown, when When , the output of hysteresis comparator 1 remains unchanged; while when , the output of the hysteresis comparator 1 will reverse, assuming that there is no delay between the driving circuit 2 and the main circuit, the direction of change of the compensation current ic will change accordingly, so that △ic will change between -H and H, that is ic is in ic * -H and ic * In the range between +H, it follows the change of ic in a sawtooth shape.

[0029] From the above control methods, the width H of the hysteresis comparator 1 has a great influence on the follow performance of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com