Process for producing brake piston

A manufacturing method and brake technology, which are applied to pistons, manufacturing tools, furnaces, etc., can solve the problems of poor manufacturing efficiency and many processes, and achieve the effects of good manufacturing efficiency, lower energy costs, and good machinability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~13

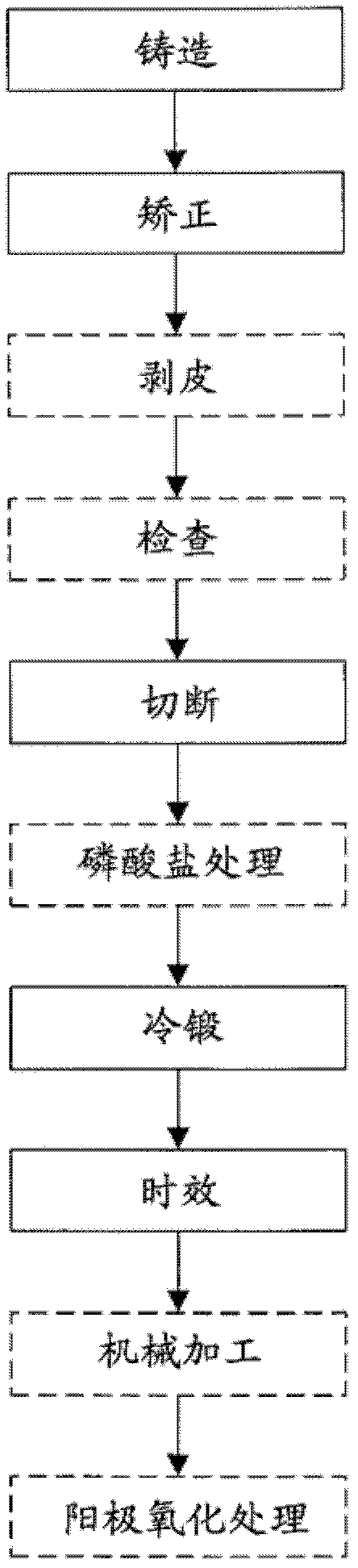

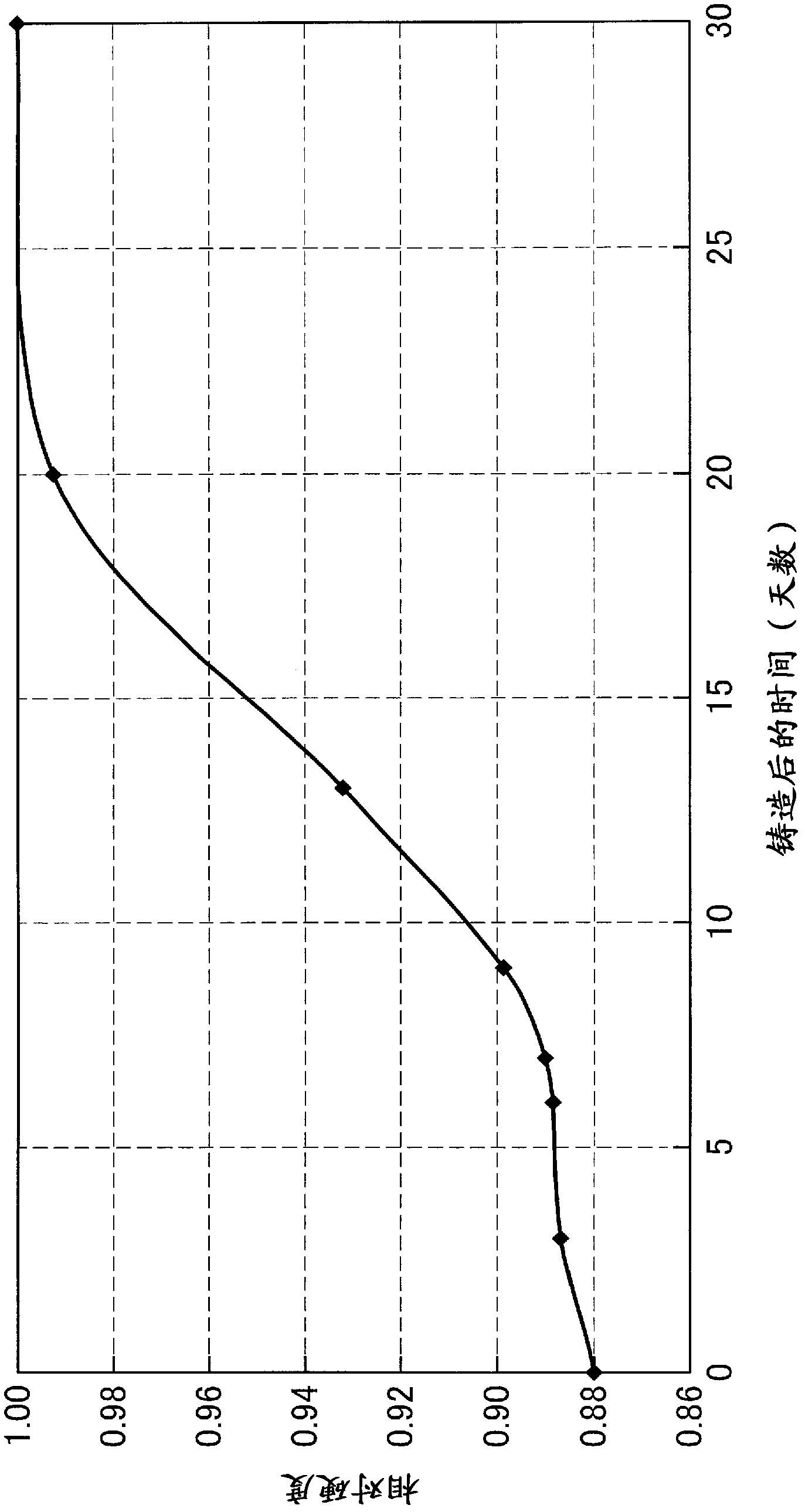

[0107] The rod-shaped ingot was corrected by nipping with a straightening roll without performing homogenization treatment 3 days after casting (72 hours later). The straightened rod-shaped ingot is peeled, and the inspected rod-shaped ingot is cut to a desired thickness and formed into a short cylinder, which is used as a forging blank (2).

[0108] The blank for forging (2) is treated with phosphate, without annealing, such as Figure 5 As shown, cold forging was carried out 7 days after casting (after 168 hours) to form a cup-shaped brake piston (1). Table 2 shows the processing ratio in cold working as any one of 25%, 50%, and 71%.

Embodiment 14、15

[0110] A cup-shaped brake piston ( 1 ) was molded by the same process as in Example 1 except that the timing of straightening and cold forging was changed as described in Table 2.

[0111] The molded brake piston was not subjected to solution treatment, but was aged at 175°C for 2 hours, and machined to improve the dimensional accuracy of the inner diameter and outer diameter.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rockwell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com