Pretreatment process for aluminum and high etch cleaner used therein

A cleaning agent and etching technology, applied in chemical instruments and methods, detergent compositions, non-surface active detergent compositions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

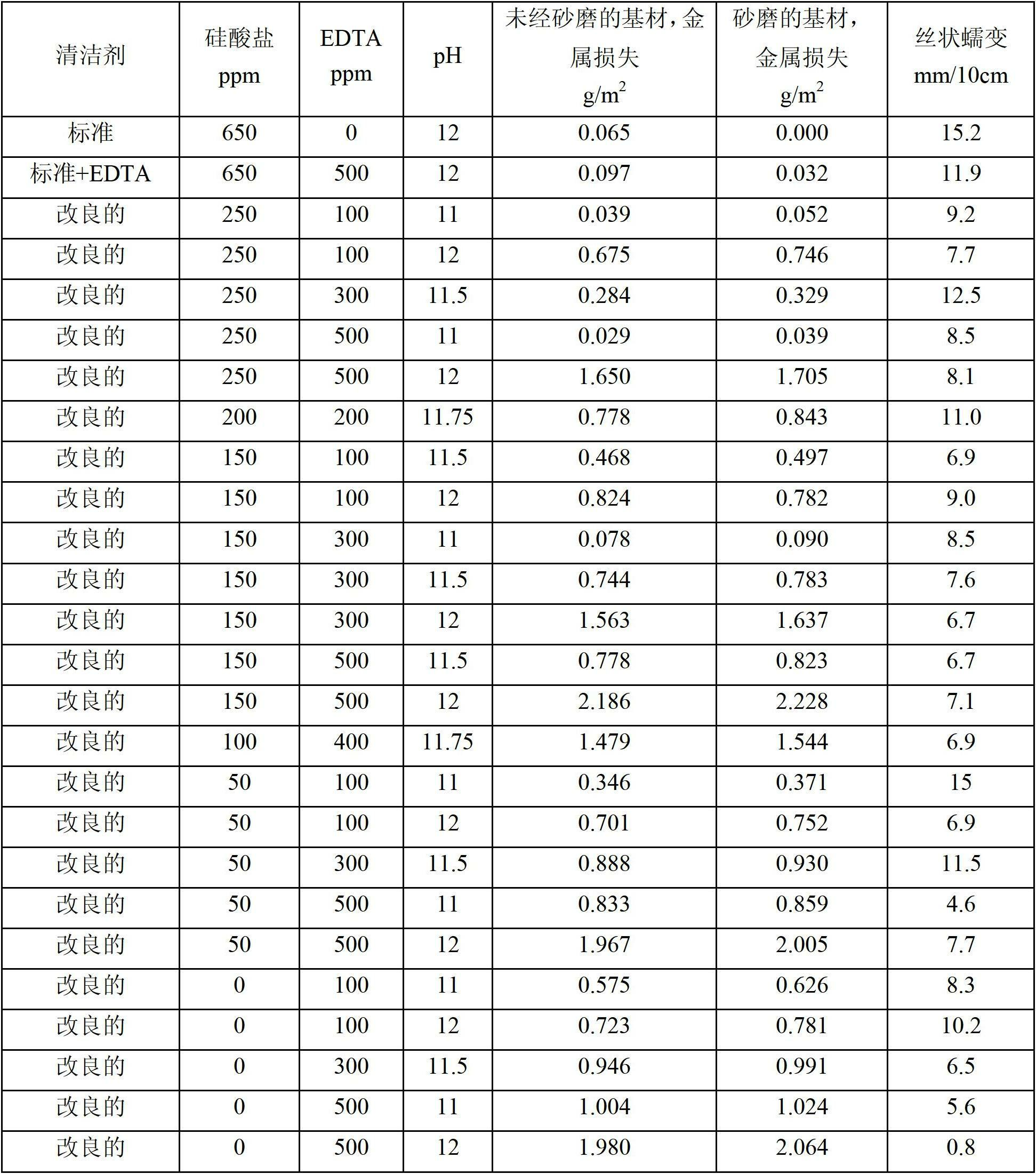

[0026] In the first series of tests, standard cleaners were modified to have reduced levels of silicates, the pH was changed, and the level of EDTA was changed. A standard cleaner was prepared by adding to water 26.0 g / L of a composition comprising 50% by weight deionized water, 46.97% by weight potassium hydroxide, and 3.03% by weight sodium trimetaphosphate. The standard cleaner also includes 1.6 g / l of surfactant and 0.3 g / l of sodium gluconate. Sodium bicarbonate was used to adjust the pH of the detergent solution. Standard cleaners were modified by adjusting the sodium silicate and EDTA levels and by adjusting the pH as shown in Table 3 below. The substrate was ACT aluminum alloy 6022 with a copper level of 0.01-0.11 wt%. The substrates were treated for etching studies as follows: the substrates were initially cleaned with an acetone dip; the cleaner was applied for 120 seconds; followed by a warm water rinse and the plates were allowed to dry. The aluminum loss due to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com