Artificial cheese and preparation method thereof

A cheese and product technology, applied in the field of simulated cheese and its preparation, can solve the problems of oiliness and uneven distribution of scorched spots, poor application characteristics of processed cheese, weak stringiness, etc., and achieve simple preparation method and mild flavor , Excellent effect of drawing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

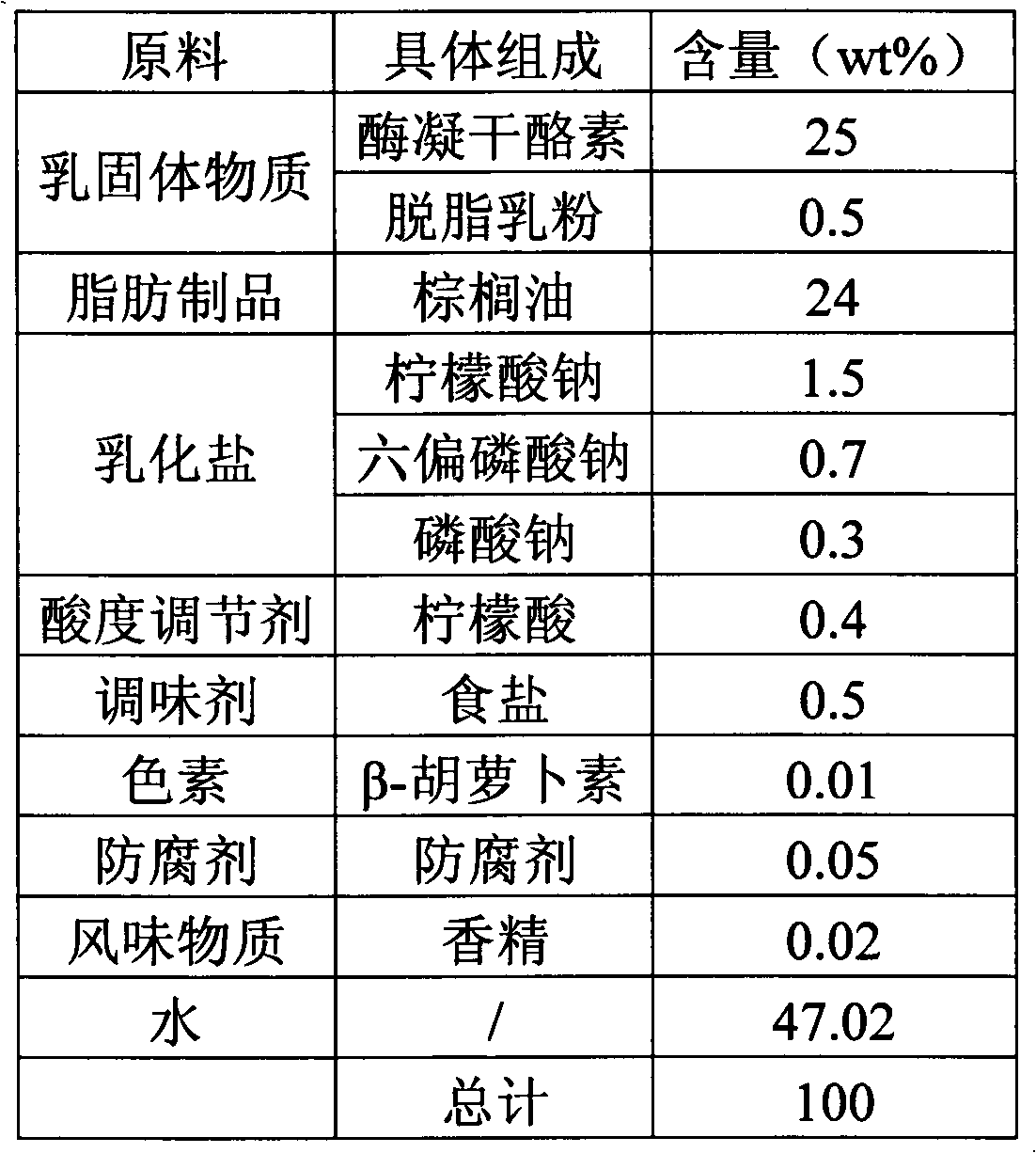

[0043] The raw material formula of simulated cheese is shown in Table 1.

[0044] The raw material formula of the simulated cheese of table 1 embodiment 1

[0045]

[0046] Mock cheese preparation method:

[0047] (1) Use 2 shearing knives with a blade thickness of 3 mm to shear and pre-mix the raw materials except fat products in a melting pot for 3 minutes, the pre-shear temperature is 20 ° C, and the pre-shear speed is 600 rpm to obtain a slurry ;

[0048] (2) Directly heat the slurry and fat products to 76°C with steam, and stir and emulsify at a speed of 600rpm for 8min;

[0049] (3) Use water cooling to cool down to 30°C within 1 hour, refrigerate at 4°C for 7 days, and use a cutting machine to cut into 3.5mm 3 Granular, that is to say.

Embodiment 2

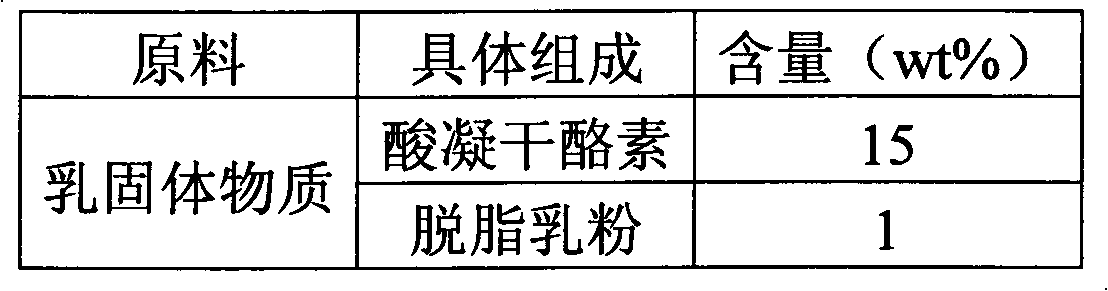

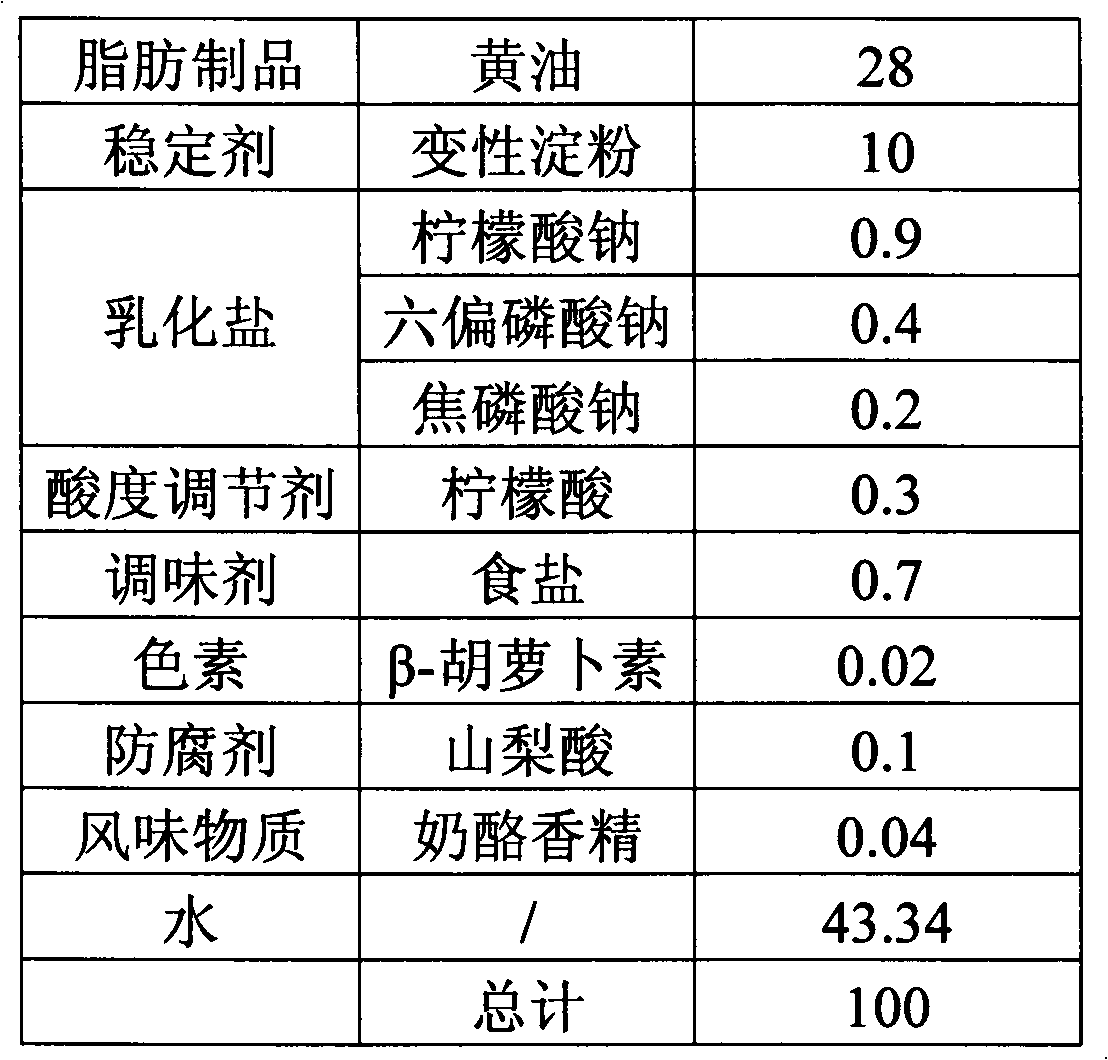

[0051] The raw material formula of simulated cheese is shown in Table 2.

[0052] The raw material formula of the simulated cheese of table 2 embodiment 2

[0053]

[0054]

[0055] Mock cheese preparation method:

[0056] (1) Use 3 shearing knives with a blade thickness of 5 mm to shear and pre-mix the raw materials except fat products in a melting pot for 3 minutes, the pre-shear temperature is 25 ° C, and the pre-shear speed is 700 rpm to obtain a slurry ;

[0057] (2) Directly heat the slurry and fat products to 90°C with steam, and stir and emulsify at a speed of 600rpm for 5min;

[0058] (3) Use air cooling to cool down to 30°C within 1 hour, refrigerate at 2°C for 2 days, and use a cutting machine to cut into 2mm 3 Granular, that is to say.

Embodiment 3

[0060] The raw material formula of simulated cheese is shown in Table 3.

[0061] The raw material formula of the simulated cheese of table 3 embodiment 3

[0062]

[0063]

[0064] Mock cheese preparation method:

[0065] (1) Use 3 shear knives with a blade thickness of 5 mm to shear and pre-mix the raw materials except fat products in a melting pot for 4 minutes, the pre-shear temperature is 30 ° C, and the pre-shear speed is 100 rpm to obtain a slurry ;

[0066] (2) Directly heat the slurry and fat products to 95°C with steam, and stir and emulsify at a speed of 100rpm for 6min;

[0067] (3) Use water cooling to cool down to 10°C within 1 hour, refrigerate at 6°C for 4 days, and use a cutting machine to cut into 5mm 3 Granular, that is to say.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com