Automatic forming equipment of pointed cone part of spiral ground pile

A technology of automatic forming and spiral ground piles, which is applied in the direction of forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems that the splicing surfaces cannot be fully fitted, the solid cone tip cannot be formed, and the force cannot be applied, etc. Long life, high processing efficiency, and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

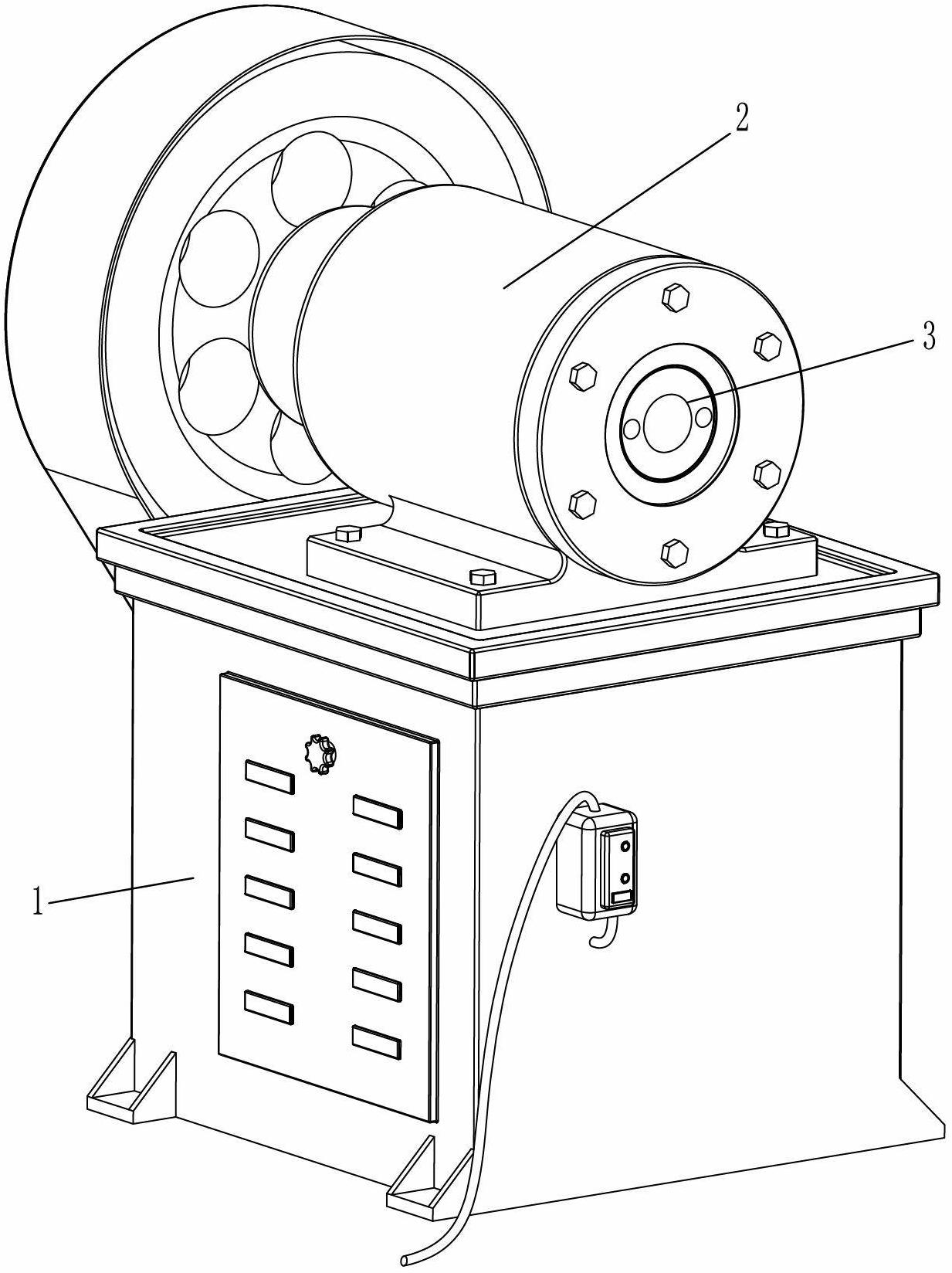

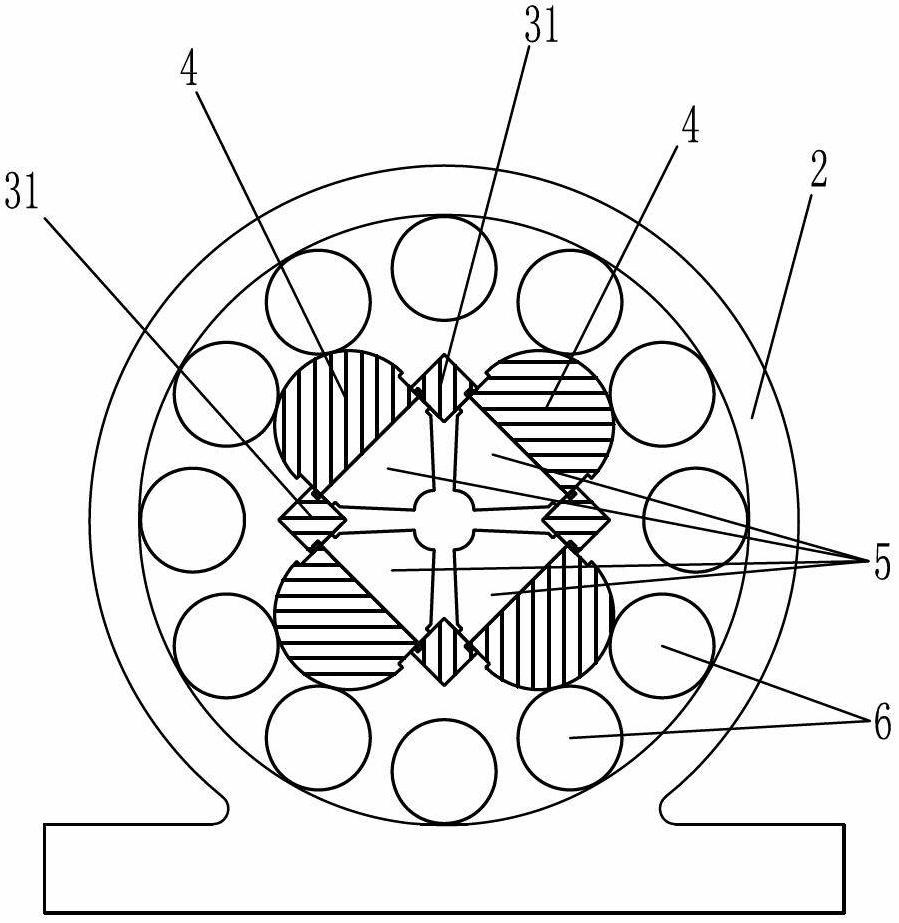

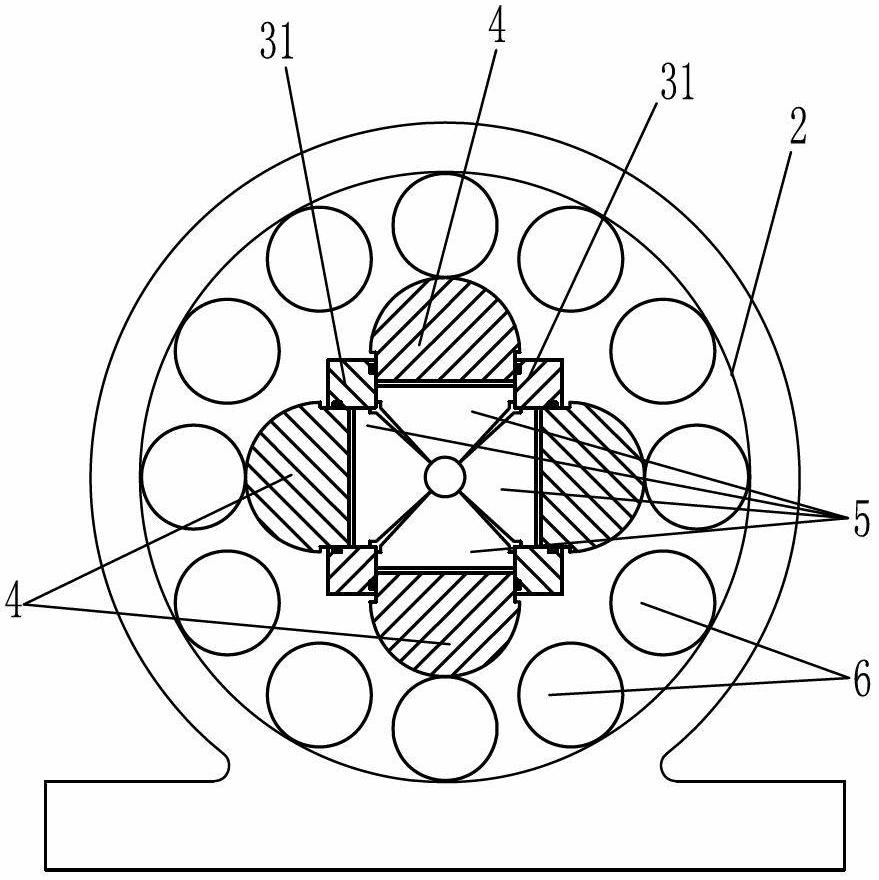

[0027] An automatic forming device for the cone of a spiral ground pile, comprising a plurality of conical tube machines distributed side by side, a frame is arranged on the feeding side of the multiple conical tube machines, and a plurality of feeding manipulators, a A feeding device and a discharging device, the plurality of feeding manipulators and the plurality of tapered tube machines are arranged in one-to-one correspondence. Wherein, the cone pipe machine such as figure 1 , figure 2 , image 3 As shown, it includes a machine base 1, a housing 2 on the machine base 1, a main shaft 3 driven by a motor through a pulley, a mold 5 and a hammer 4 are installed in the mold cavity of the main shaft 3, and between the hammer 4 and the housing 2 Roller group 6 is arranged between, described hammerhead 4 comprises four hammerhead blocks, and described mold 5 is made up of four petal mold blocks with the same structure, and the splicing part of each petal mold block is triangula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com