Multi-stage combined vibration isolation and vibration damping device of automatic molding machine of building block

A vibration damping device and automatic molding technology, applied in ceramic molding machines, auxiliary molding equipment, manufacturing tools, etc. Problems such as low technical performance of special materials for vibration reduction, to achieve the effect of expanding the effective vibration coverage area, high strength level and shape precision, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

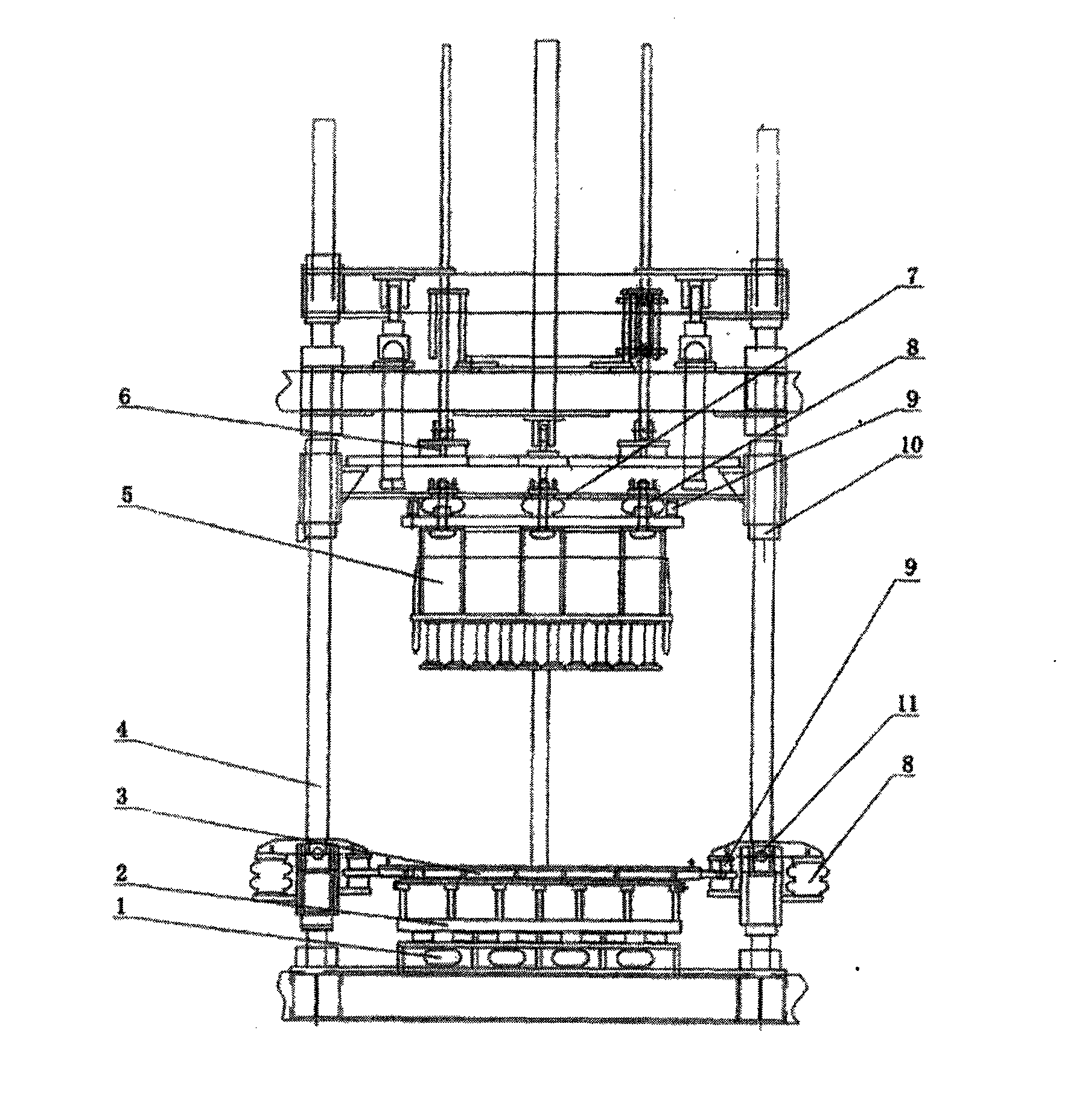

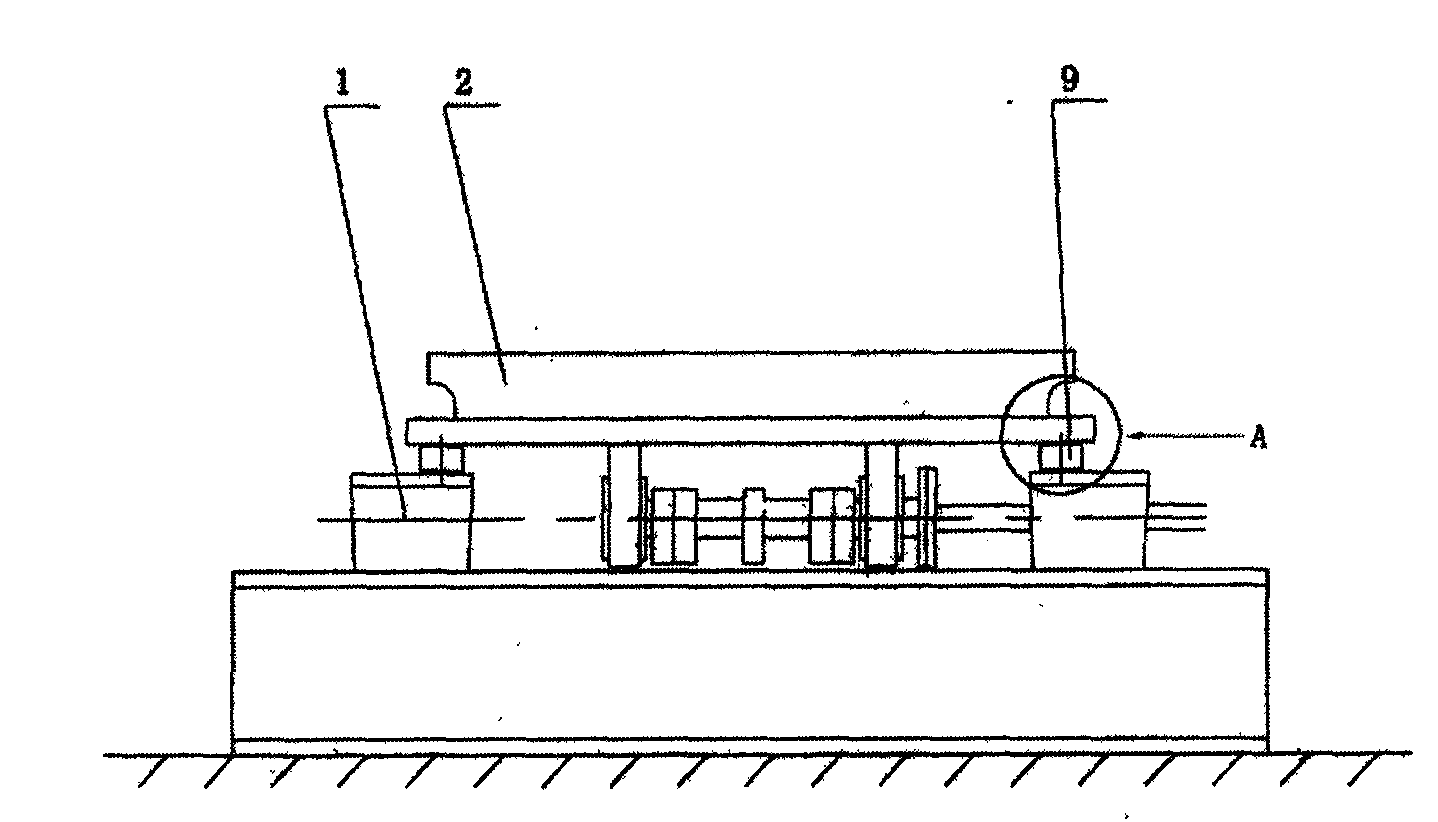

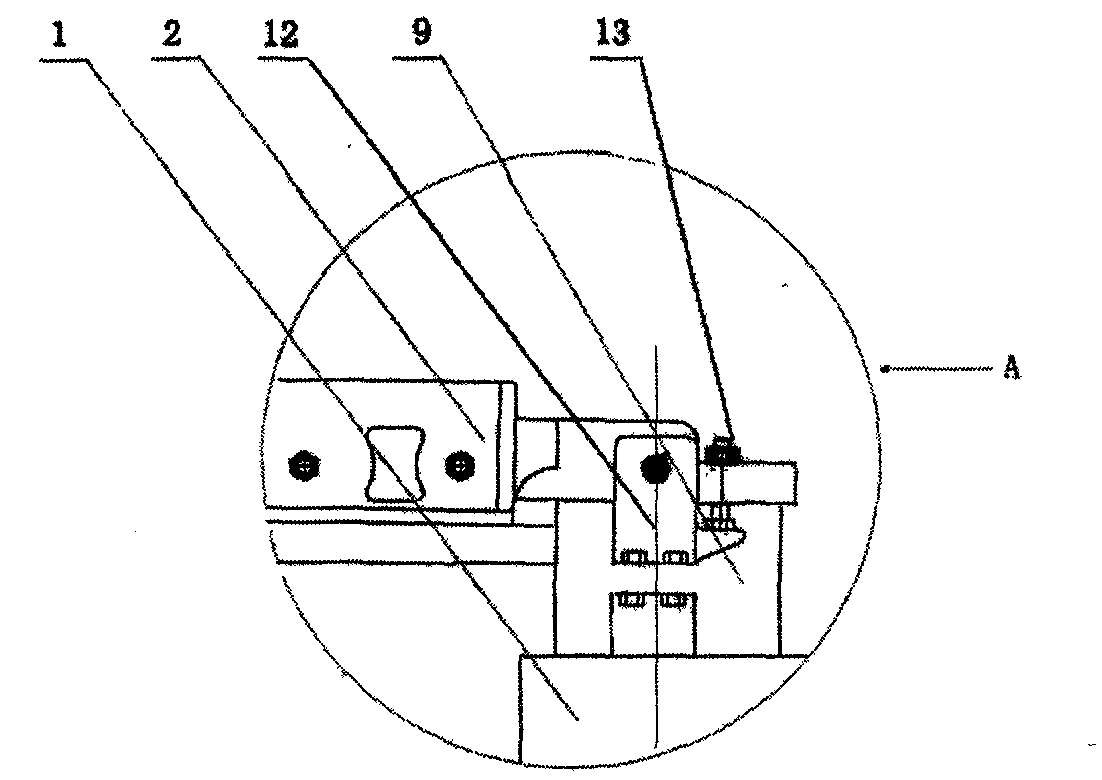

[0026] as attached Figure 5 , attached Figure 6 , attached Figure 7 As shown, the multi-stage combined vibration isolation and vibration reduction device for block automatic forming machinery of the present invention includes vibration isolation and vibration reduction in three different structural forms: high pressure air spring (8), vibration damping block (9), and shaft coupling (16). Vibration-specific functional components, and the primary foundation vibration isolation and vibration reduction devices formed by combined connection and installation in the vibrating operation components. The high-pressure air spring (8), damping block (9), and coupling (16) are all made of hard rubber fiber material with special material and structural characteristics. According to the different operation functions and structural characteristics of the continuous transmission of table and shaft parts, different combinations and different connection and installation technical measures a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com