Titanium-rich lamellar Ti-Si molecular sieve and compound method thereof

A technology of titanium-silicon molecular sieve and synthesis method, which is applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problems of low olefin chain olefin epoxidation activity and low skeleton Ti content, and achieve high chain olefin epoxidation Effects of catalytic activity, increased framework titanium content, and good catalytic performance for the epoxidation of macrocyclic olefins and unsaturated ketones

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

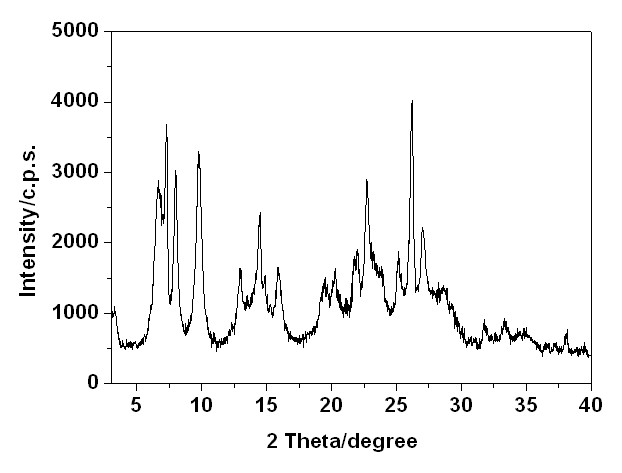

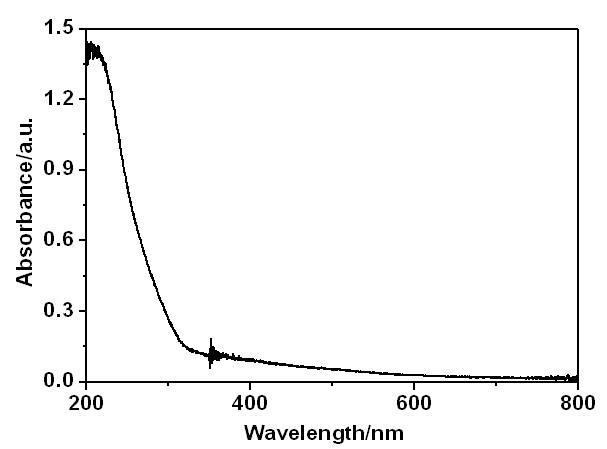

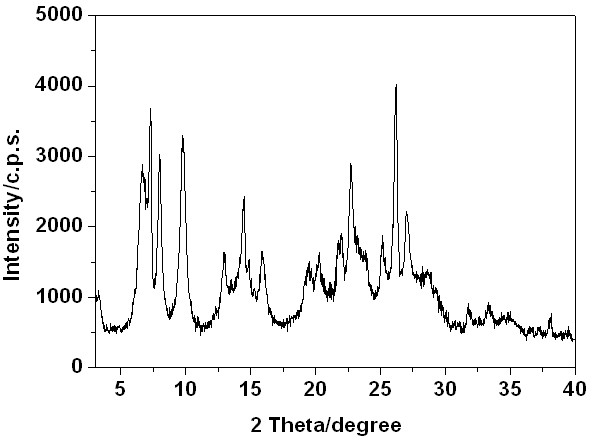

Image

Examples

Embodiment 1

[0032] (1) The first step: B-MWW molecular sieves with deep deboronization are prepared by the following method: gel synthesis made of silicon source, boron source, organic template agent and water, wherein the silicon source is silica sol, organic template The agent is hexamethyleneimine, the boron source is boric acid, the silicon source and the boron source are SiO 2 and B 2 o 3 In terms of molar ratio, the gel is composed of SiO 2 :B 2 o 3 : organic templating agent: H 2 O = 1:0.65:1.4:19, crystallized at 170 o C was carried out at a constant temperature for 7 days to obtain the product, and the product was filtered, washed, and 100 o C dry and 550 o After C was roasted for 10 hours, it was treated with 6 mol / L nitric acid under boiling conditions for 22 hours, and the nitric acid solution / calcined B-MWW = 40 mL / g. The acid-treated product is filtered, washed and dried to obtain a deep deboronated B-MWW molecular sieve.

[0033] (2) In the second step, the reactio...

Embodiment 2

[0038] (1) In the first step: gel synthesis made of silicon source, boron source, organic template agent and water, wherein the silicon source is silica, the organic template agent is piperidine, the boron source is boric acid, and the silicon source and boron source respectively as SiO 2 and B 2 o 3 In terms of molar ratio, the gel is composed of SiO 2 :B 2 o 3 : organic templating agent: H 2 O = 1:0.65:1.4:19, crystallized at 170 o C was carried out at a constant temperature for 7 days to obtain the product, and the product was filtered, washed, and 100 o C dry and 550 o After C was roasted for 10 hours, it was treated with 6 mol / L nitric acid under boiling conditions for 22 hours, and the nitric acid solution / calcined B-MWW = 40 mL / g. The acid-treated product is filtered, washed and dried to obtain a deep deboronated B-MWW molecular sieve.

[0039] (2) In the second step, the reaction mixture is composed of deeply deboronated B-MWW molecular sieves in molar ratio: ...

Embodiment 3

[0044] (1) In the first step: gel synthesis made of silicon source, boron source, organic template agent and water, wherein the silicon source is silica, the organic template agent is piperidine, the boron source is boric acid, and the silicon source and boron source respectively as SiO 2 and B 2 o 3 In terms of molar ratio, the gel is composed of SiO 2 :B 2 o 3 : organic templating agent: H 2 O = 1:0.65:1.4:19, crystallized at 170 o C was carried out at a constant temperature for 7 days to obtain the product, and the product was filtered, washed, and 100 o C dry and 550 o After C was roasted for 10 hours, it was treated with 6 mol / L nitric acid under boiling conditions for 22 hours, and the nitric acid solution / calcined B-MWW = 40 mL / g. The acid-treated product is filtered, washed and dried to obtain a deep deboronated B-MWW molecular sieve.

[0045] (2) In the second step, the reaction mixture is composed of deeply deboronated B-MWW molecular sieves in molar ratio: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com