Short-process slag stewing water returning technology

A short-flow, stuffy slag technology, applied in the production process of the metallurgical industry, can solve the problems of long return water process, poor effect, and increased construction costs, so as to reduce water vapor evaporation loss, increase return water circulation rate, reduce The effect of installation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

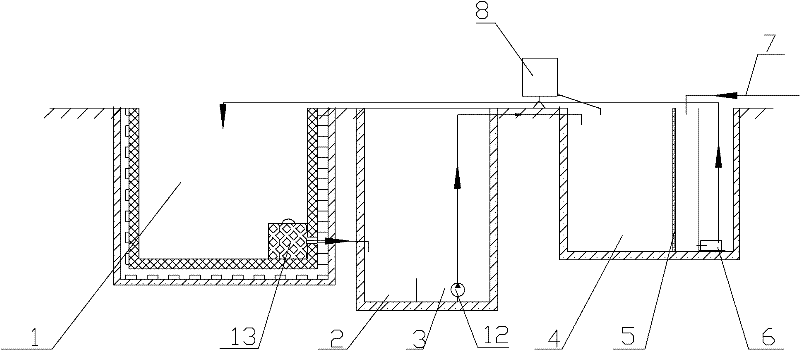

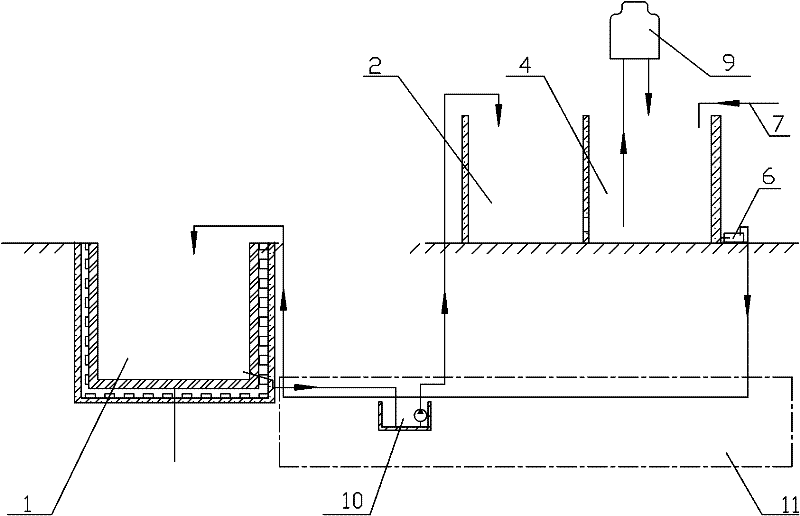

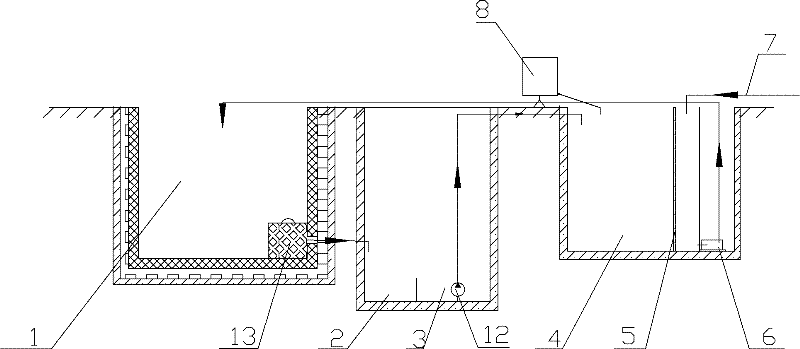

[0019] See figure 1 , a short-flow slag return process, including slag tank 1, sedimentation tank 2, water purification tank 3, water absorption tank 4, sedimentation tank 2 and water purification tank 3 are built underground, sedimentation tank 2 and water purification tank 3 The bottom is lower than the 1 bottom of the stuffy slag pool. The backwater at the bottom of the slag pool 1 passes through the steel mesh cage 13 equipped with large-grained ore to intercept the large impurities, and the water flows through the drainage ditch to the sedimentation tank 2 for sedimentation and then overflows to the clean water pool 3. Each slag pool corresponds to A settling tank and a water purification tank, the water purification tank 3 is provided with a submersible pump 12, and the clean water is pumped into a public underground water absorption tank 4, and added to the water absorption tank 4 after dispensing in the medicine box 8, which can soften the water quality and prevent Pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com