Manufacturing equipment system of flame-retardant polyester fiber

A technology of polyester fiber and manufacturing equipment, which is used in the manufacture of fire-retardant and flame-retardant filaments, single-component polyester rayon, etc. The effect of excellent and durable fabric flame retardant performance, excellent fiber physical properties, and excellent washing durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

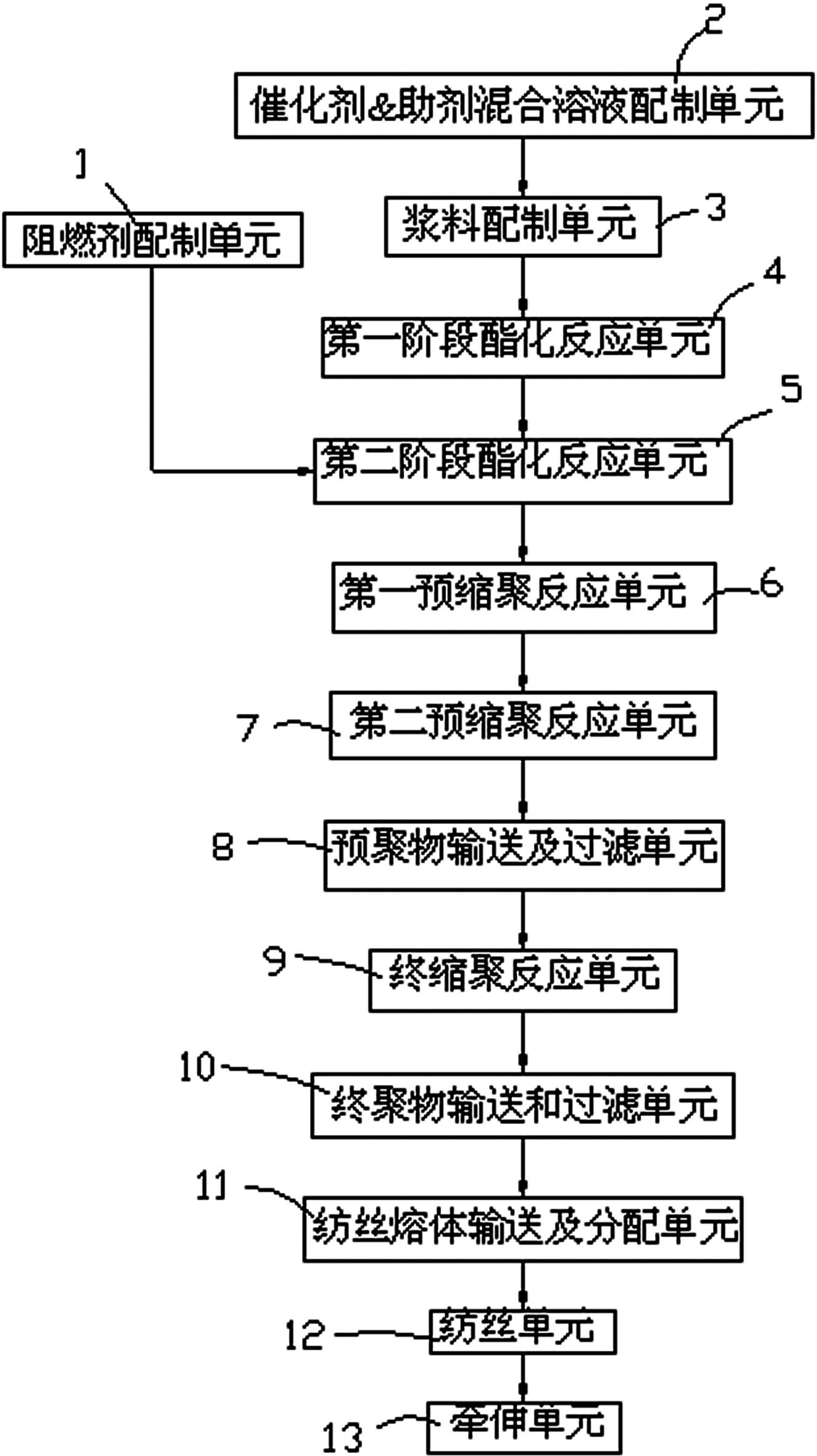

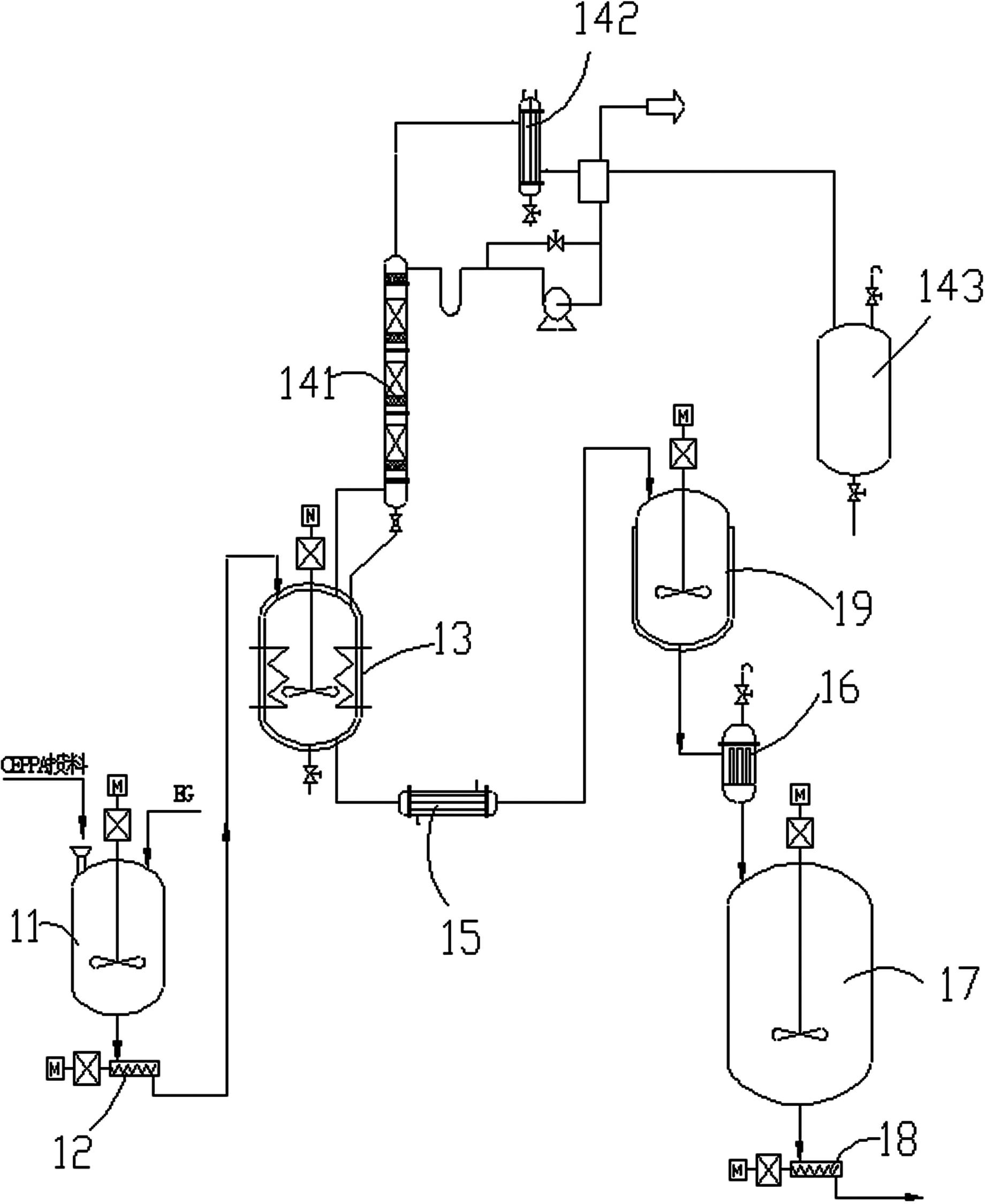

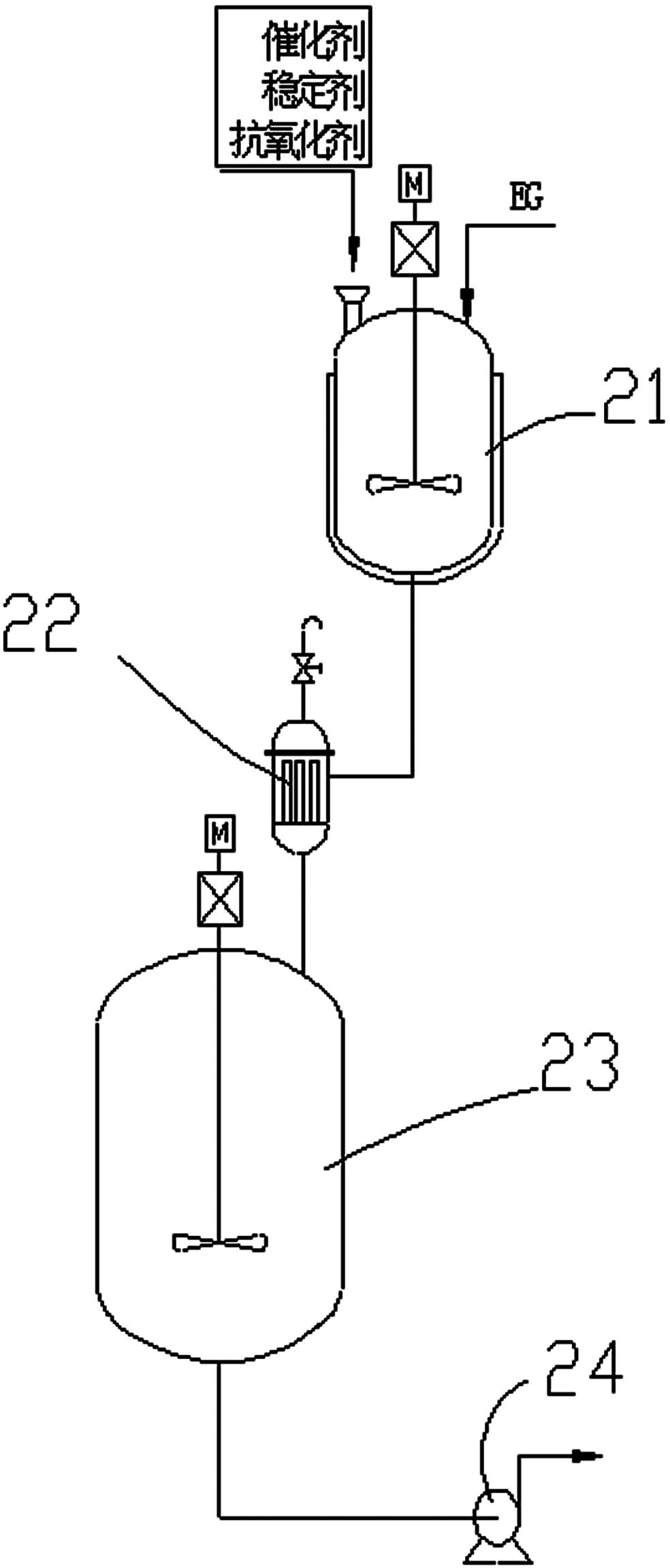

[0029] see Figure 1 to Figure 6 As shown, the manufacturing equipment system of the flame-retardant polyester fiber of the present invention includes a flame retardant preparation unit 1, a catalyst & auxiliary agent mixed solution preparation unit 2, a slurry preparation unit 3, a first-stage esterification reaction unit 4, The second stage esterification reaction unit 5, the first precondensation reaction unit 6, the second precondensation reaction unit 7, the prepolymer conveying and filtering unit 8, the final polycondensation reaction unit 9, the final polymer conveying and filtering unit 10, the spinning Silk melt delivery and distribution unit 11, spinning unit 12 and drafting unit 13; the slurry preparation unit 3, the first stage esterification reaction unit 4, the second stage esterification reaction unit 5, the first precondensation reaction Unit 6, the second precondensation reaction unit 7, prepolymer conveying and filtering unit 8, final polycondensation reactio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com