Ultralow-speed flow box device

A headbox, ultra-low speed technology, applied in textile and paper making, paper machine, wet end of paper machine, etc., can solve the problems of low spraying speed, high cost, unable to meet the requirements of the liquid level of the homogenizing roll, etc. Achieve the effect of reducing equipment cost, simple and easy technical means, positive technical effect and promotion and application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

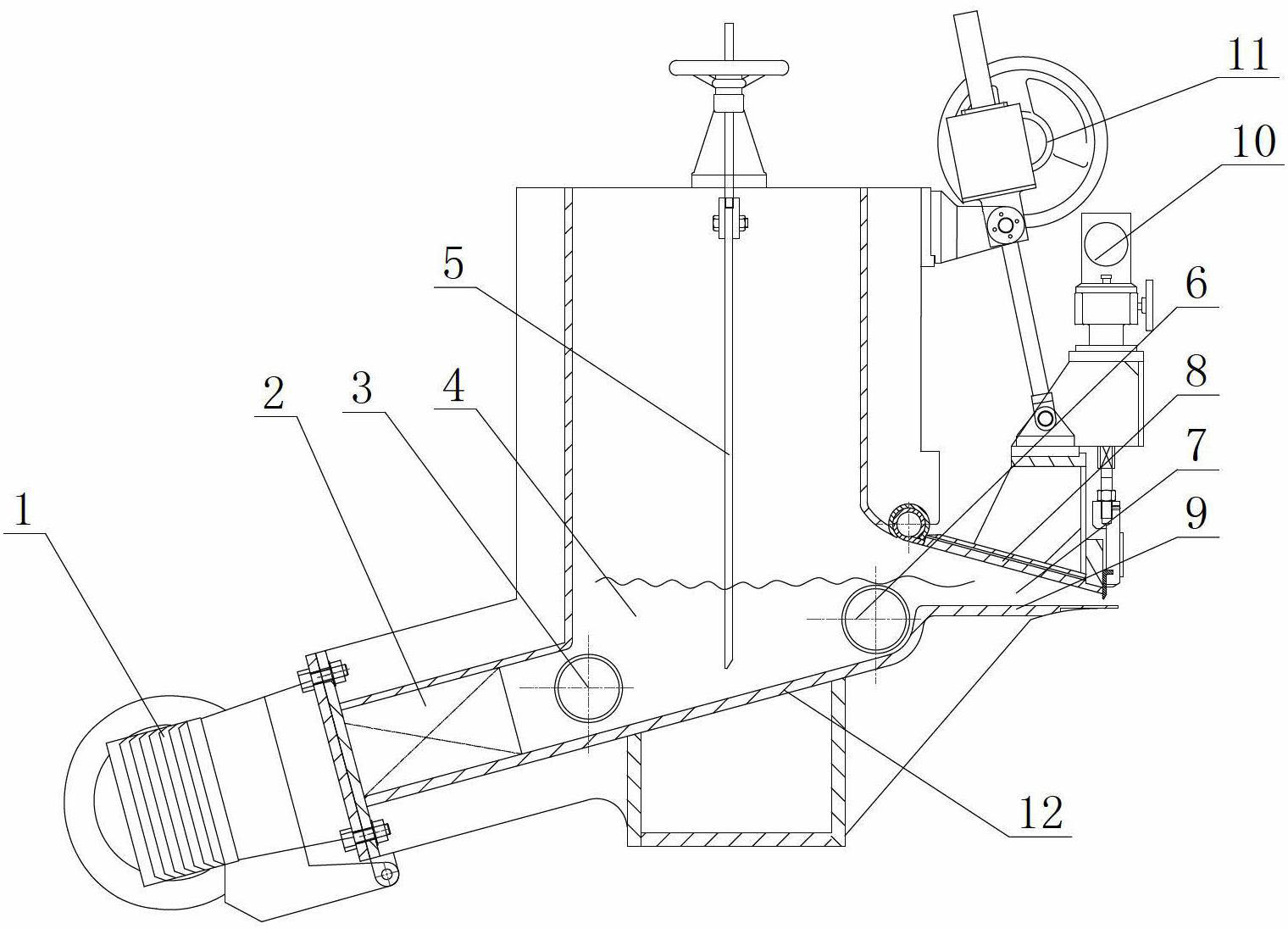

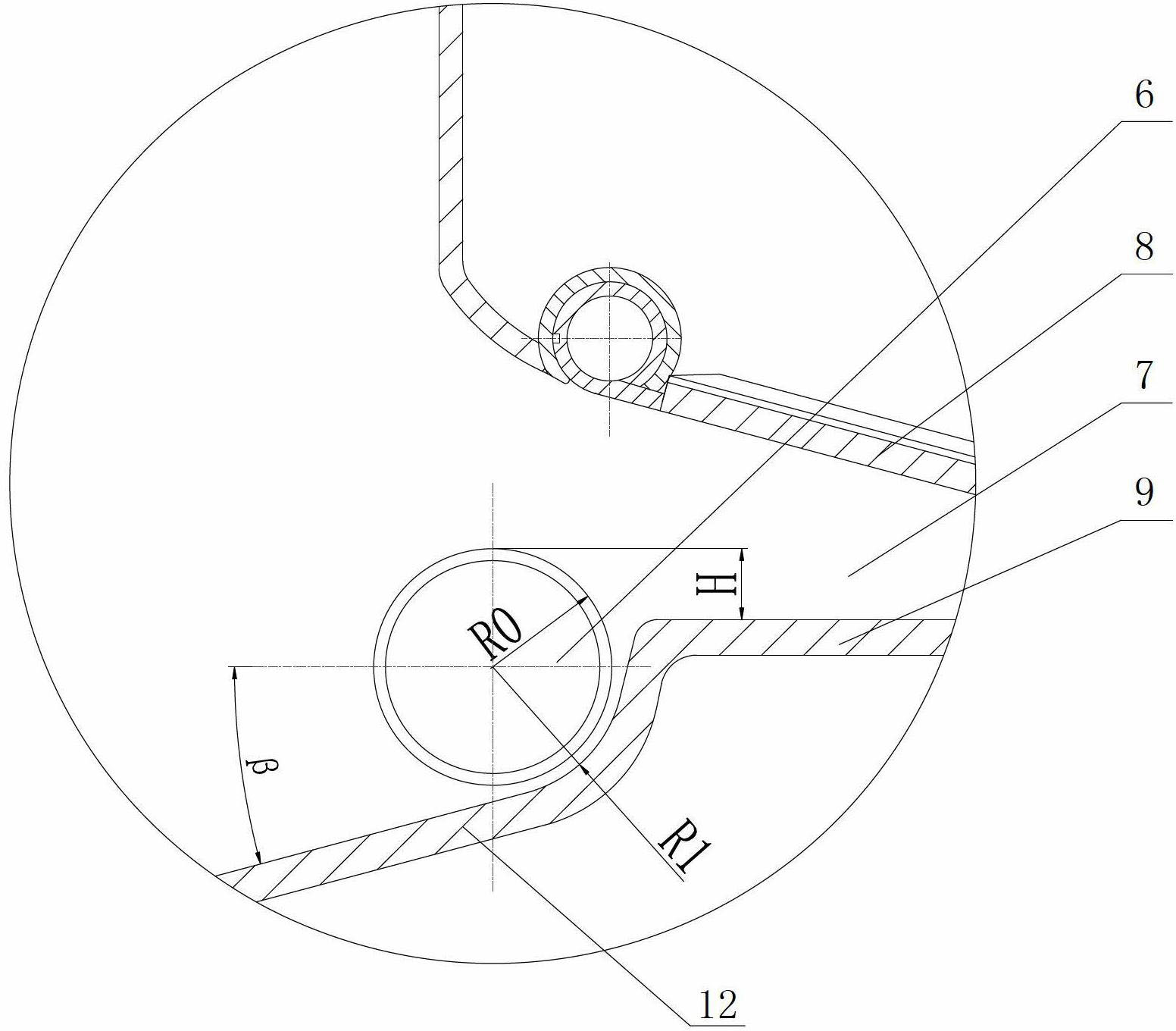

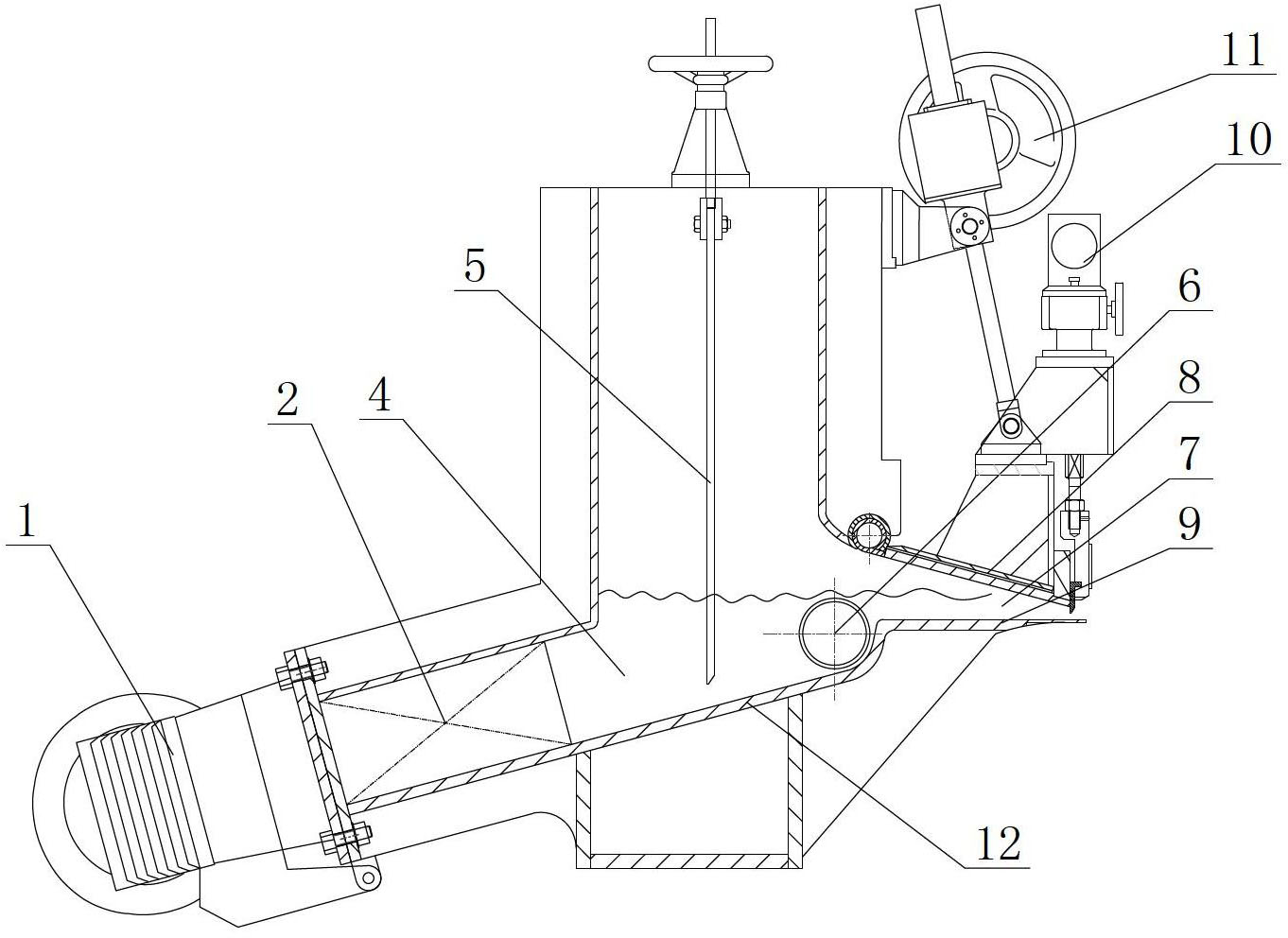

[0023] Such as figure 1 As shown, the ultra-low-speed headbox device of the present invention includes a stock inlet main pipe 1, a stock distribution element 2, an energy-dissipating homogenizer roller 3, a weir pool 4, a flashboard 5, a rectifier homogenizer roller 6, a lip area 7, an upper lip Plate 8, lower lip 9, fine-tuning device 10, upper lip lifting device 11, headbox bottom 12; the inner bottom of the headbox bottom 12 is inclined upward to the lower lip 9 and transitions with the lower lip 9 in an arc Connected, the rectifying and homogenizing roller 6 is installed at the arc transition, and the energy-dissipating homogenizing roller 3 is arranged at the outlet of the pulp distribution element 2 .

[0024] Such as image 3 As shown, the slurry inlet main pipe 1 is a square cone main pipe or a conical main pipe, and the slurry distribution element 2 is one of an orifice plate, a stepped diffuser or a tube bundle. Because the slurry coming out of the stepped diffuse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com