Generator set with super-long maintenance period

A generator set and maintenance cycle technology, applied in the direction of machines/engines, mechanical equipment, combined air filters and mufflers, etc., to achieve the effects of noise reduction, easy control and adjustment, and reduced air intake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

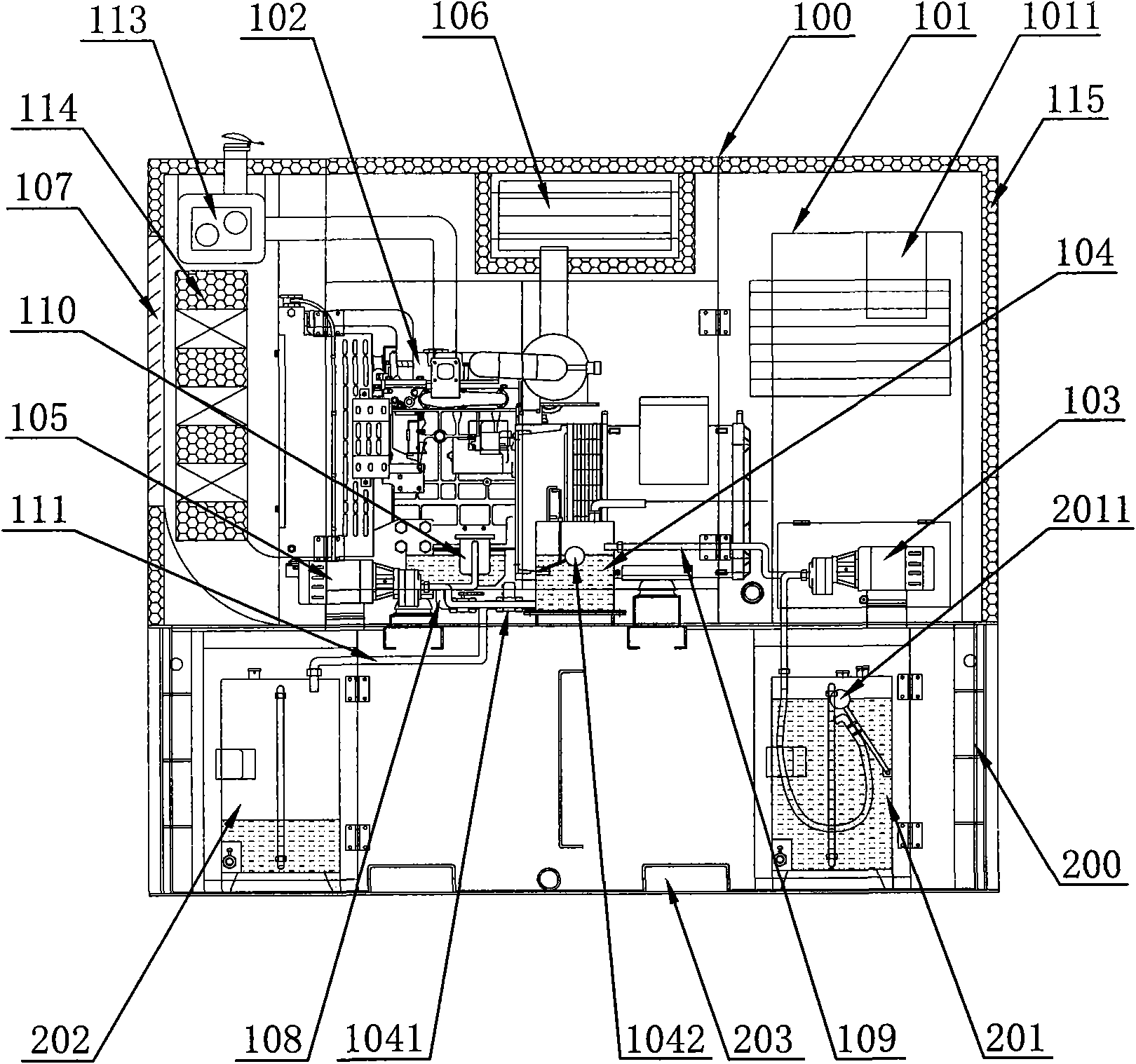

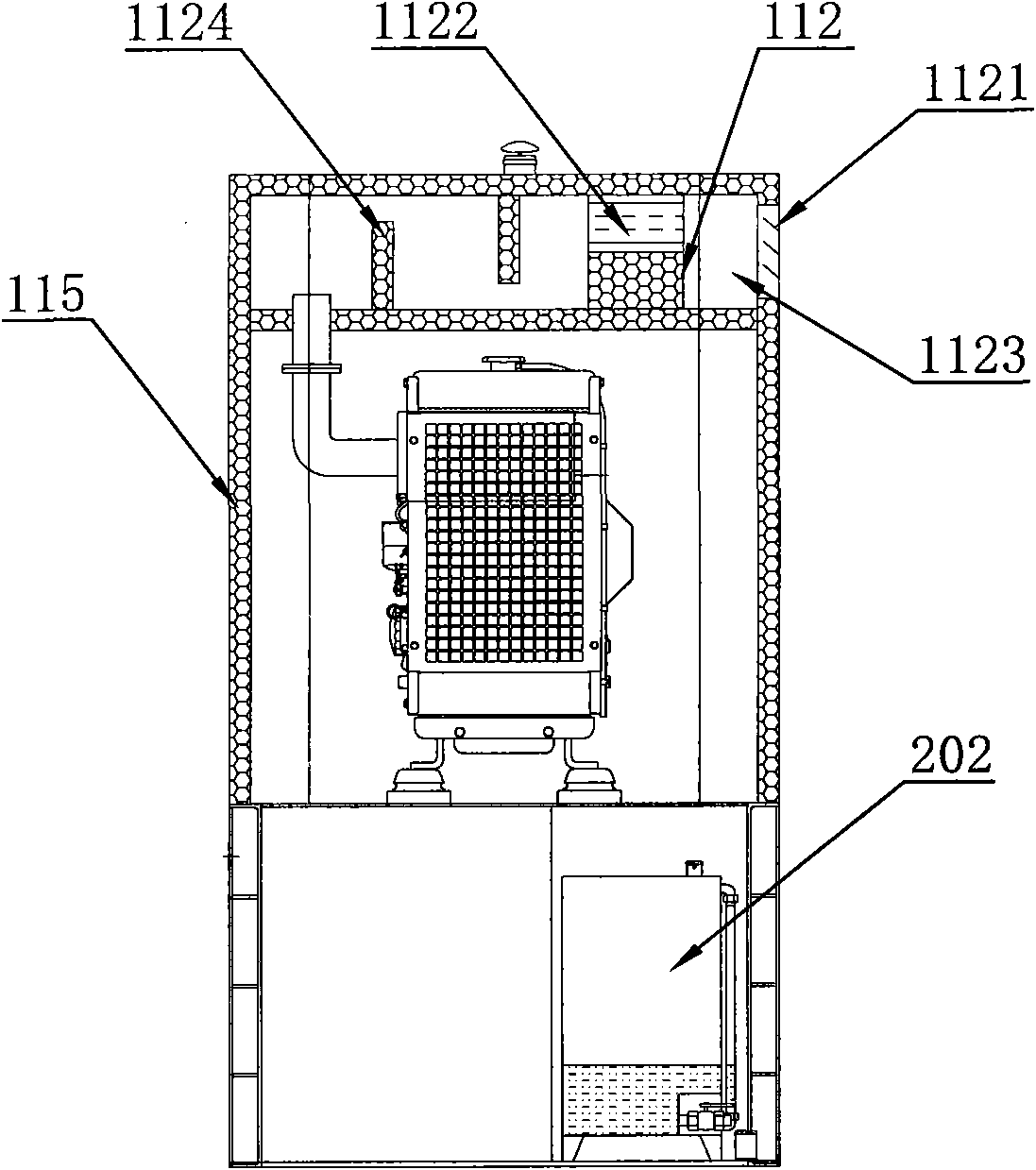

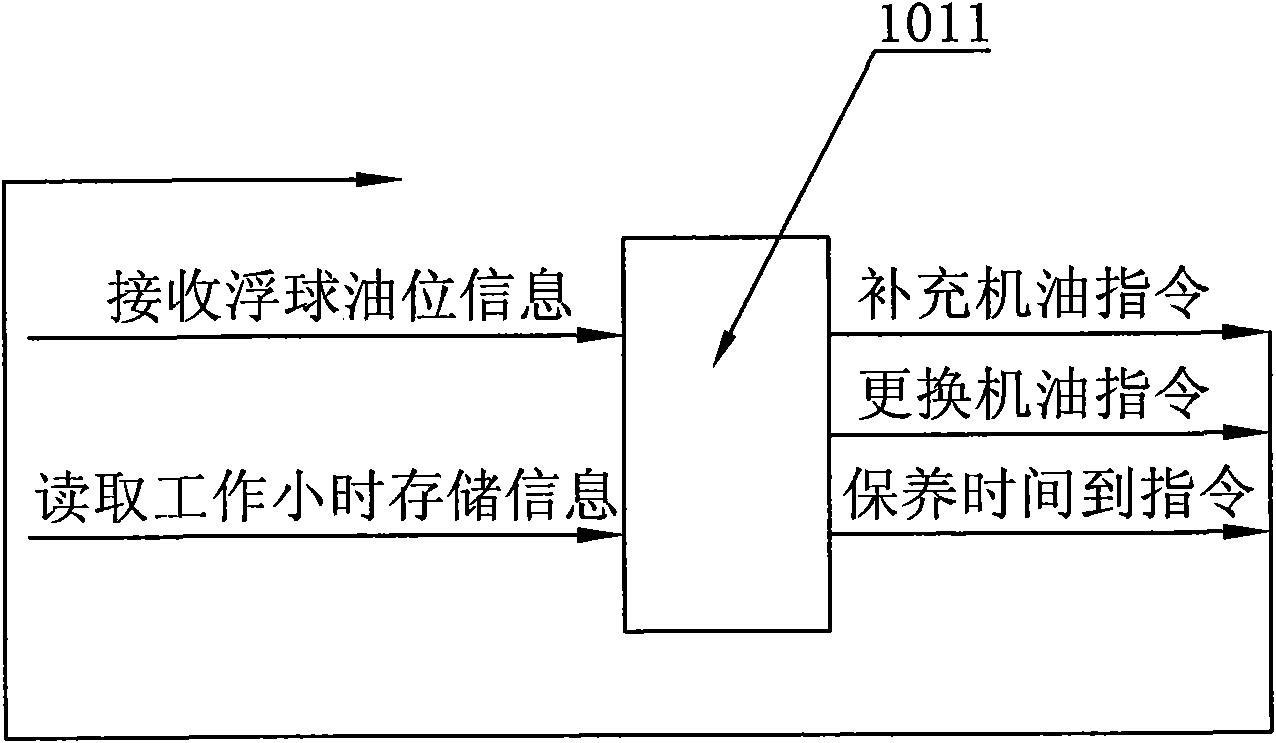

[0034] Such as Figure 1 to Figure 3 Shown is an embodiment of an ultra-long maintenance cycle generator set according to the present invention, which includes an outer box 100 and a base 200. Long maintenance module 1011, unit control cabinet 101, generator set 102, engine oil supply pump 103, engine oil oil level control box 104, and engine oil circulation oil pump 105, and an air inlet 106 and an air outlet 107 are arranged on the wall of the outer box 100, and the base 200 is also equipped with oil tank 201, waste oil tank 202, and oil tank inspection door. The intelligent remote long-distance maintenance module 1011 is equipped with a module for reading and storing unit working hours information, oil level information, maintenance time information, and unit control cabinet. 101 is provided with a controller and a display instrument, a solenoid valve 1041 is provided on the oil level control box 104, a floating ball 1042 is provided in the oil level control box 104, and th...

Embodiment 2

[0046] Also refer to Figure 1 to Figure 3 The difference between the ultra-long maintenance cycle generator set in this embodiment and the first embodiment is that a float type oil suction pipe 2011 is provided in the sump oil tank 201, and one end of the float type oil suction pipe 2011 is located in the sump sump 201, and the other end is connected to the oil supply pump. 103 connections.

[0047] Floats are commonly used to measure liquid levels in many fields, and the oil supply pipe in the sump 201 of the generator set in this embodiment always absorbs the clean oil on the oil surface through the floating floats. This design is more reasonable and convenient for practical operation.

Embodiment 3

[0049] Also refer to Figure 1 to Figure 3 The difference between the ultra-long maintenance period generator set in this embodiment and Embodiment 1 is that a display instrument is installed in the unit control cabinet 101, and an observation window is set at a position corresponding to the unit control cabinet 101, so as to facilitate observation of the operation of the generator set 102. The real-time data status is convenient for control, adjustment, and maintenance, which enhances the practicability and rationality of the generator set.

[0050] In addition, a carrying hole 203 (forklift carrying hole or lifting hole, designed according to actual use needs) is provided at the bottom of the base 200, thereby enhancing the convenience of moving the generator set and making hoisting and transportation more convenient. The base 200 bottom is also provided with a fuel tank for a diesel tank, an oil level gauge for a diesel tank, and an oil discharge port for a diesel tank.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com