Visual narrow rectangular channel aerosol motion deposition system

A rectangular channel and deposition system technology, applied in the field of multiphase flow, can solve the problems of design and processing difficulties, inability to measure the velocity field and concentration field in real time online, and inability to observe the continuous motion of aerosol particles online, and achieve detailed observation and measurement. , the effect of real-time observation and measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

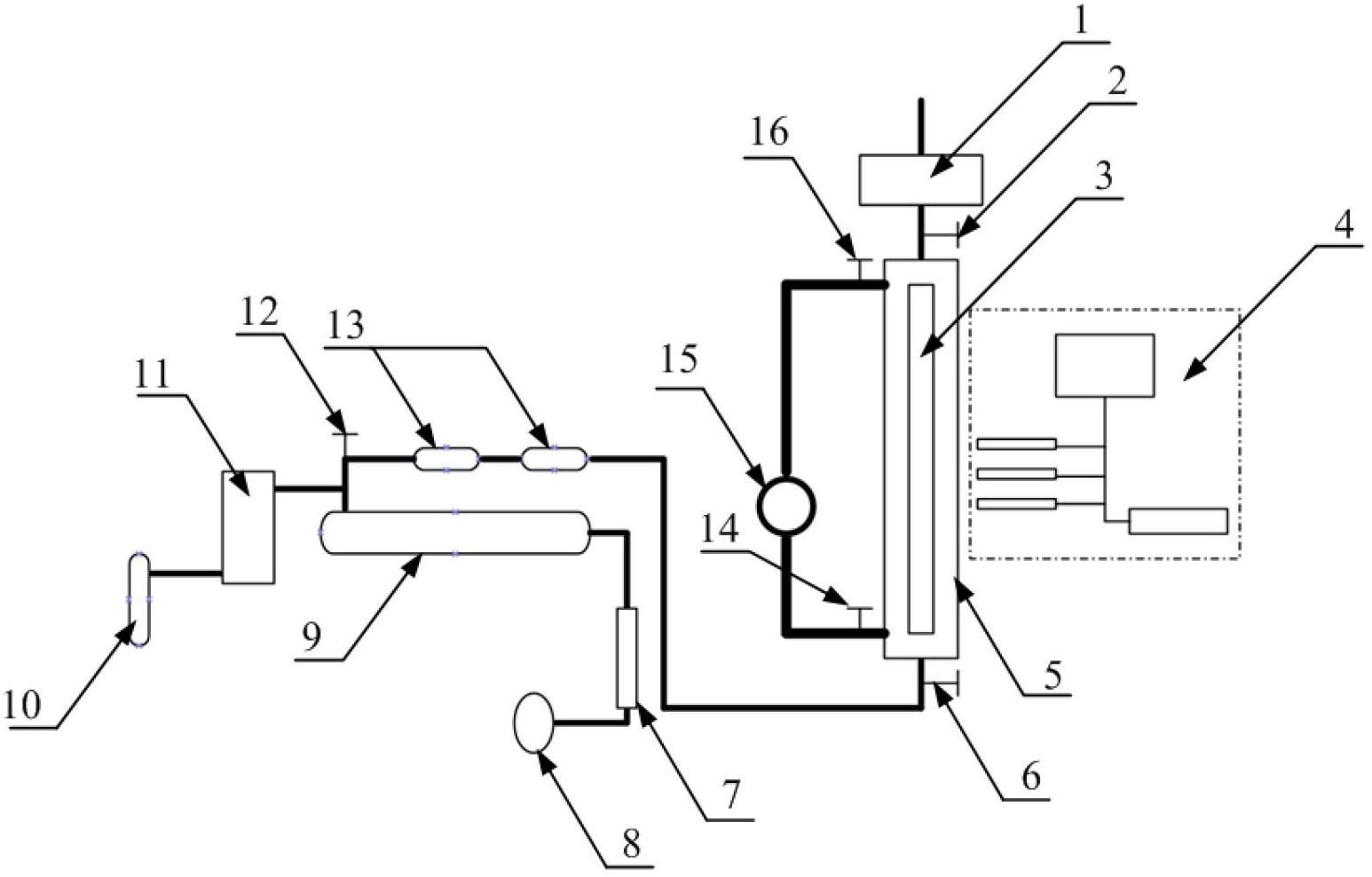

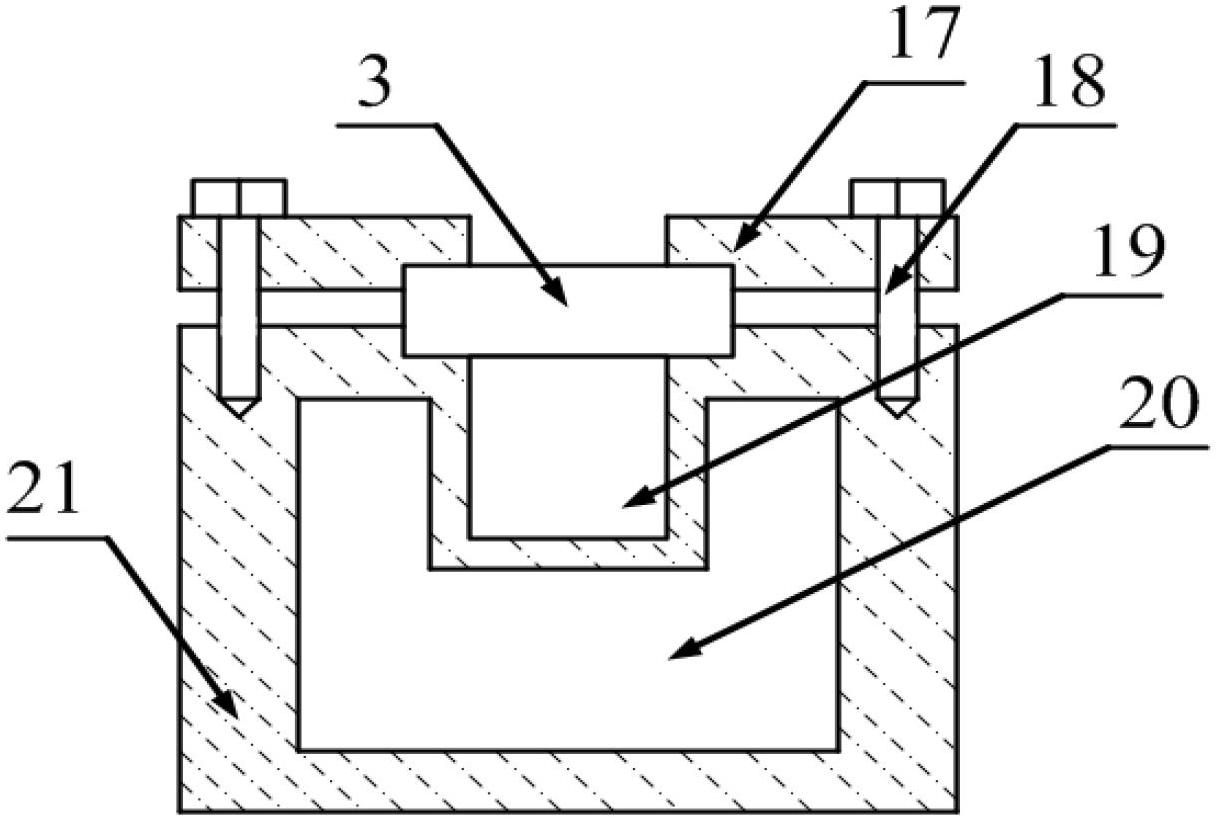

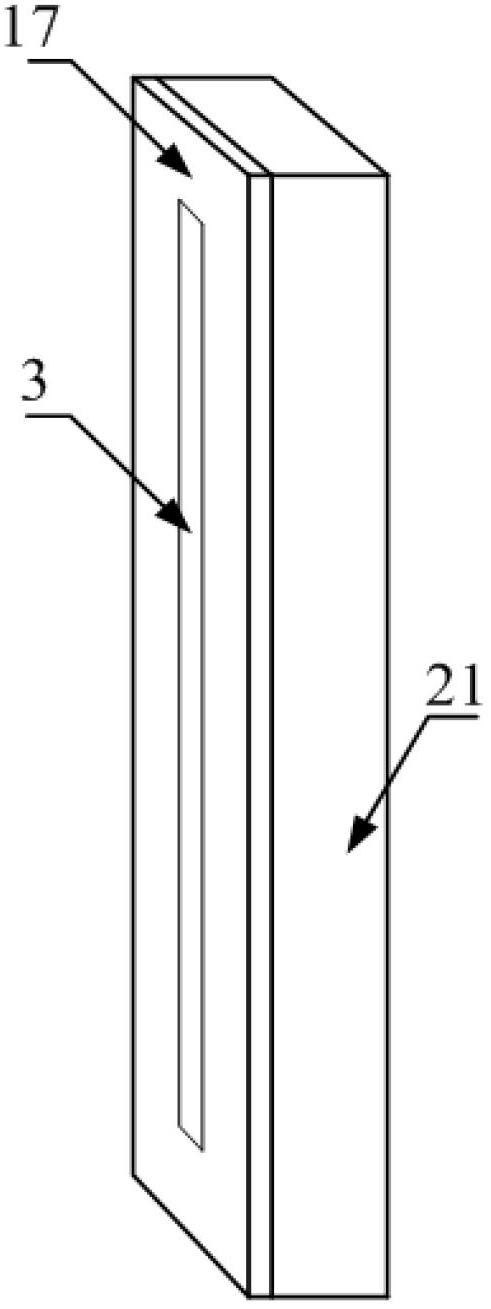

[0026] Such as figure 1 As shown, this system includes: an exhaust gas purification device 1, a thermocouple 2 at the outlet end of the visible section, a thermocouple 6 at the inlet end of the visible section 5, and a thermocouple 6 at the inlet end of the visible section are connected in sequence, and the visible section 5 is equipped with a quartz glass window 3, and the aerosol The observation equipment 4 is opposite to the quartz glass window 3, the rotameter 7 is connected to the fan 8 and the heater 9 respectively, the heater 9 is connected to the aerosol generator 11 and the thermocouple 12 at the outlet end of the heater respectively, and the aerosol generator 11 is connected to the thermocouple 12 at the outlet end of the heater. The gas cylinder 10 is connected, the thermocouple 12 at the outlet end of the heater is connected with th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com