Onsite-level low-cost redundancy measuring and controlling network based on wired and wireless hot spare redundancy communication

A redundant communication and wired communication technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problem of high operating costs and achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with specific embodiments.

[0028] Field-level low-cost redundant measurement and control network based on wired and wireless hot standby redundant communication:

[0029] (1) Application occasions - field-level measurement and control network

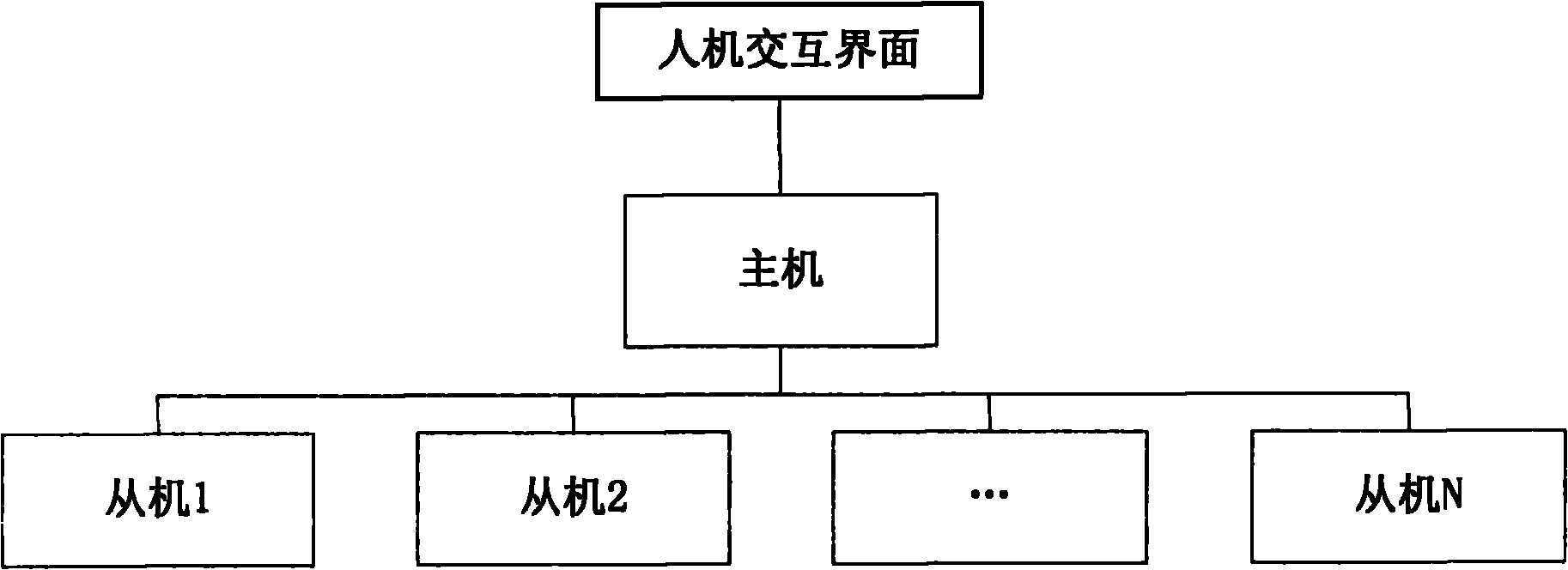

[0030] in such as figure 1 In the field-level measurement and control network using the master-slave communication mode shown, the master polls / controls the slaves to obtain the status of the slaves and the monitoring objects of the slaves, or controls the corresponding controlled objects through the slaves.

[0031] (2) Slave

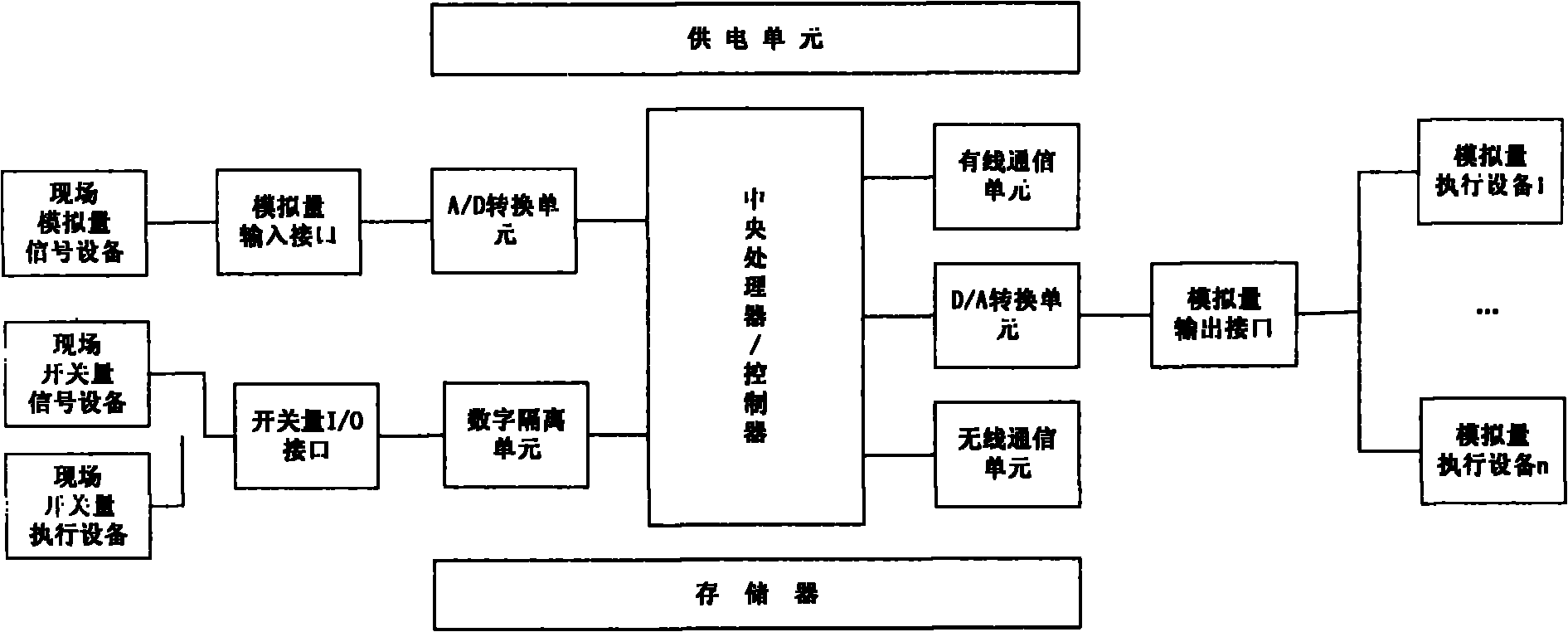

[0032] A slave in the system is an I / O module with wired and wireless redundant communication capabilities. refer to figure 2 , the slave machine can use a variety of embedded platforms, such as using ARM, DSP, MSP430 or 51 single-chip microcomputer as the central processor / controller, and then equipped with peripheral I / O and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com