Materials and methods for thermal and electrical conductivity

A technology of conductive composite materials and thermal interface materials, which is applied in metal material coating technology, circuits, thin material processing, etc., and can solve the problems that the system cannot be used commercially and the film is not self-supporting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

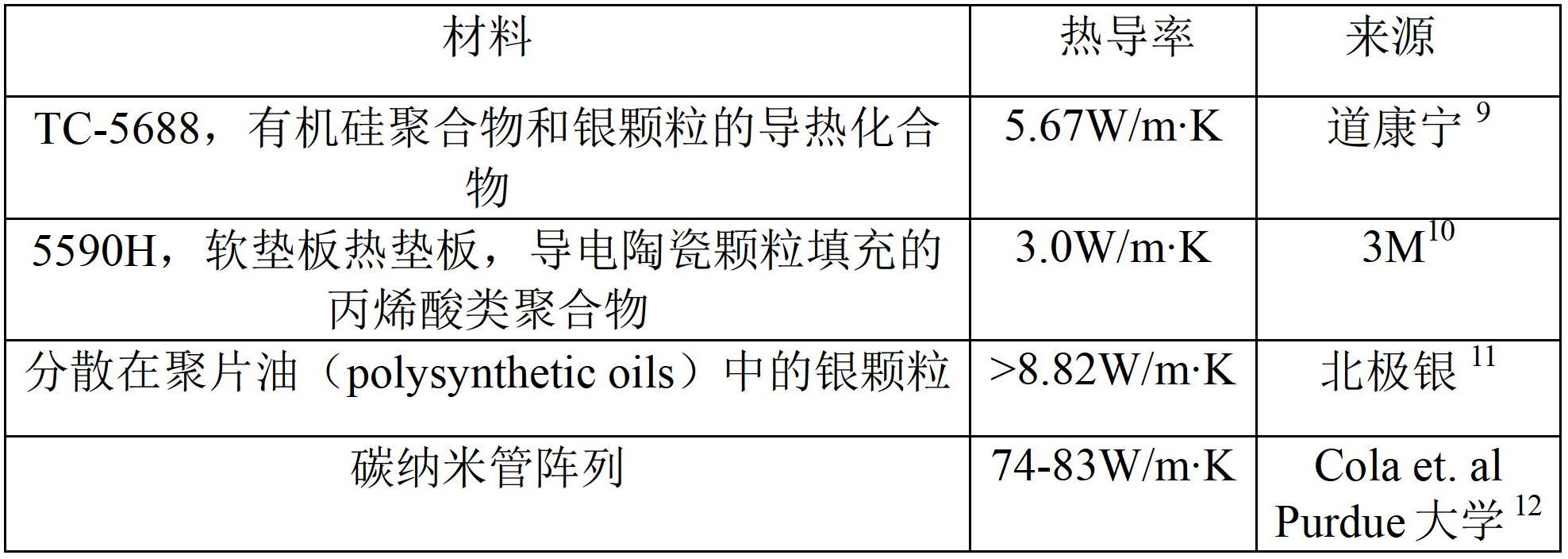

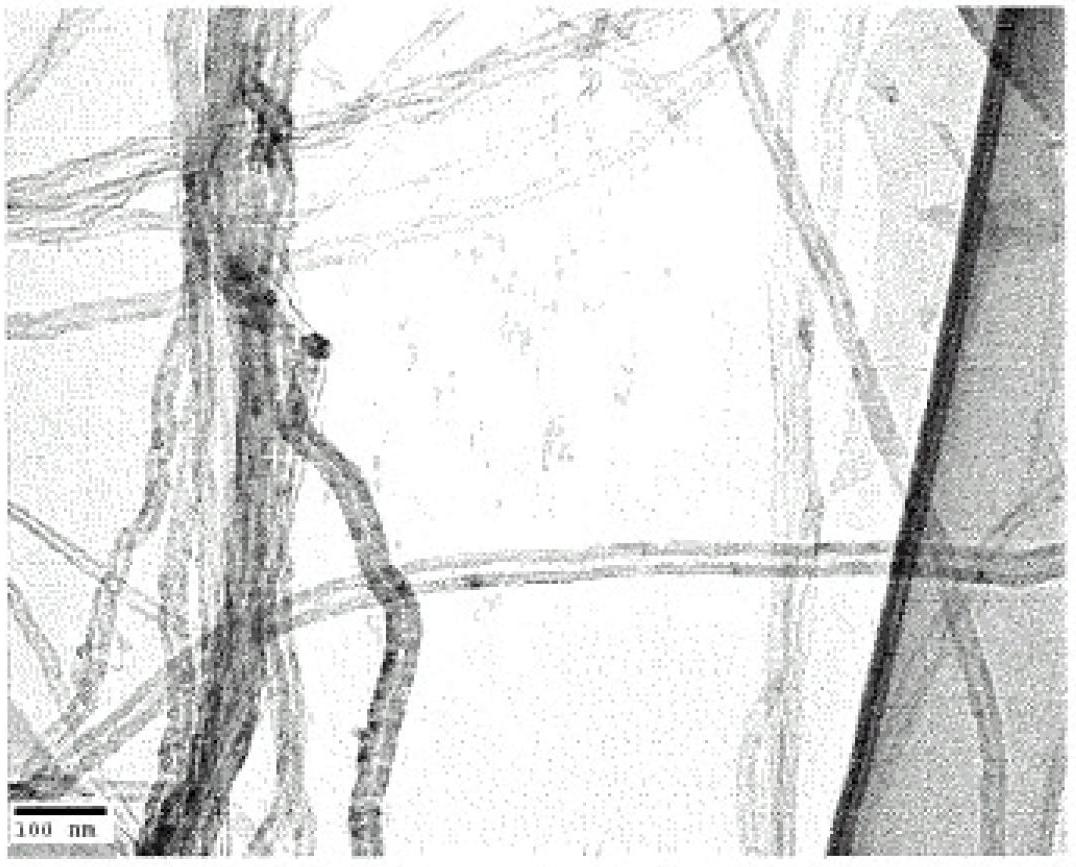

[0032] First, carbon nanotubes (CNTs) have excellent heat transfer properties. Embodiments of carbon nanotube arrays for use as thermal interface materials will be described in this disclosure, but it should be understood that other carbon nanostructures may be used as appropriate. In the present invention, thermal interface materials provide enhanced and efficient heat transfer between interfaces. With regard to carbon nanotube type adhesives, there is a relationship between heat transfer, electron conduction and adhesion. The design of the carbon nanotube-based thermal interface material ("TIM") of the present invention is based on the quantitative study of the mechanical, electrical and thermal properties of carbon nanotubes. The present invention can be synthesized on geometries suitable for integration with existing radiator systems. In one embodiment, aligned multi-walled carbon nanotubes (MWCNTs) are synthesized to enhance more efficient heat transfer properties. In ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| bulk modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com