High-energy liquid blasting separated type farm-oriented material throwing device and throwing method

A separate, liquid explosion technology, applied in the field of material dispersal, can solve the problems of uneven material dispersal, complicated cannon operation, lack of practicability, etc., and achieve the effect of improving competitiveness, simple operation technology and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1, a separate high-energy liquid explosion device for throwing agricultural materials

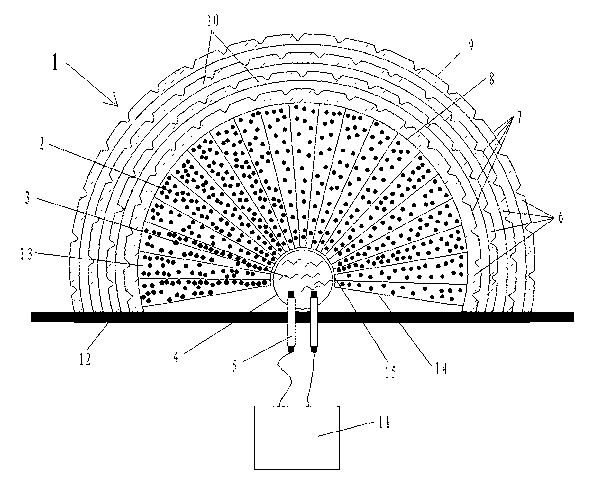

[0035] Such as figure 1 , 2 3, use cardboard material as the burstable open container 1 of hemispherical shell-shaped papery shell 6, the open container 1 that can burst is provided with many non-burstable partitions 14 of thin steel plate material arranged radially by a center, these The non-burstable partitions 14 arranged radially divide the inner space of the burstable open container 1 into many strip-shaped small tubes 13 made of a thin steel plate arranged radially at the center, and the center of the radial arrangement is located at the center of the opening surface of the burstable open container 1 The central end of strip tubule 13 can be sealed with thin paper bursting membrane 15, and all strip tubules 13 that are connected in a radial arrangement are taken out from the open container 1 that can burst, and at the far end of each strip tubule 13 The opening is fil...

Embodiment 2

[0037] Embodiment 2. The shell of the burstable open container is a high-energy liquid explosion separated agricultural material device with two inner and outer layers.

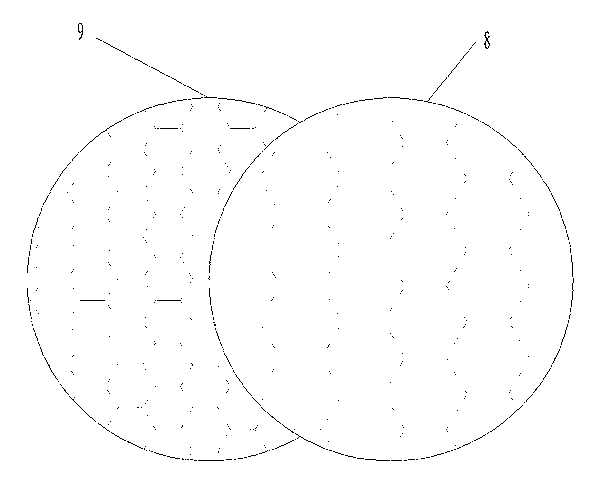

[0038] Such as figure 1 , 2 , 3, as in embodiment 1, the shell 6 of the open container 1 that can burst is two layers inside and outside, and the two layers inside and outside are respectively a tortoise-shaped structure with grooves between a plurality of small plates 7. And all the tortoise shells of the inner layer 8 have the same shape and size, all the tortoise shells of the outer layer 9 have the same shape and size, and the tortoise shell shape area of the inner layer 8 is larger than the tortoise shell shape of the outer layer 9. This structure is conducive to evenly throwing agricultural materials around after blasting 2 .

Embodiment 3

[0039] Embodiment 3, the burstable open container shell is a four-layer high-energy liquid explosion separated agricultural material device

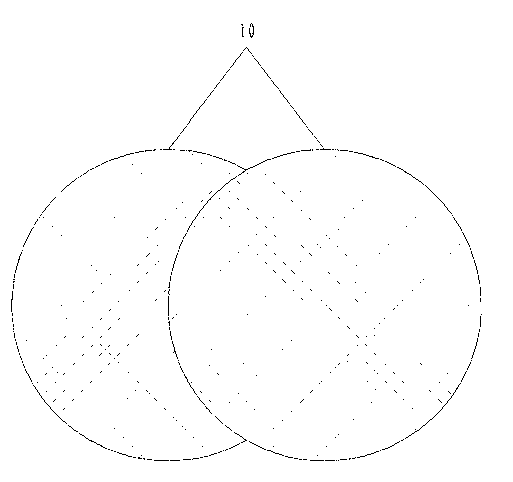

[0040] Such as figure 1 , 2 , 3, as embodiment 3, the shell 6 of the burstable open container 1 is four layers, and wherein the inner and outer layers are respectively a tortoise-shaped structure with grooves between a plurality of small plates 7. And all the tortoise shells of the inner layer 8 have the same shape and size, all the tortoise shells of the outer layer 9 have the same shape and size, and the tortoise shell shape area of the inner layer 8 is greater than the tortoise shell shape of the outer layer 9 . Also be provided with uniform distribution layer 10 between inner layer 8 and outer layer 9, uniform distribution layer 10 is two layers, and the platelet 7 of uniform distribution layer 10 is the bar shape that length and width are unequal; Its long sides of strip-shaped small plate 7 are perpendicular to each other. Thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com