Oolong tea twisting machine

A kneading machine and oolong tea technology, applied in tea treatment before extraction, etc., can solve the problems of inability to carry out large-scale production, low production efficiency, uneven tea quality, etc., achieve obvious volume reduction rate, increase production efficiency, maintain original taste and quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

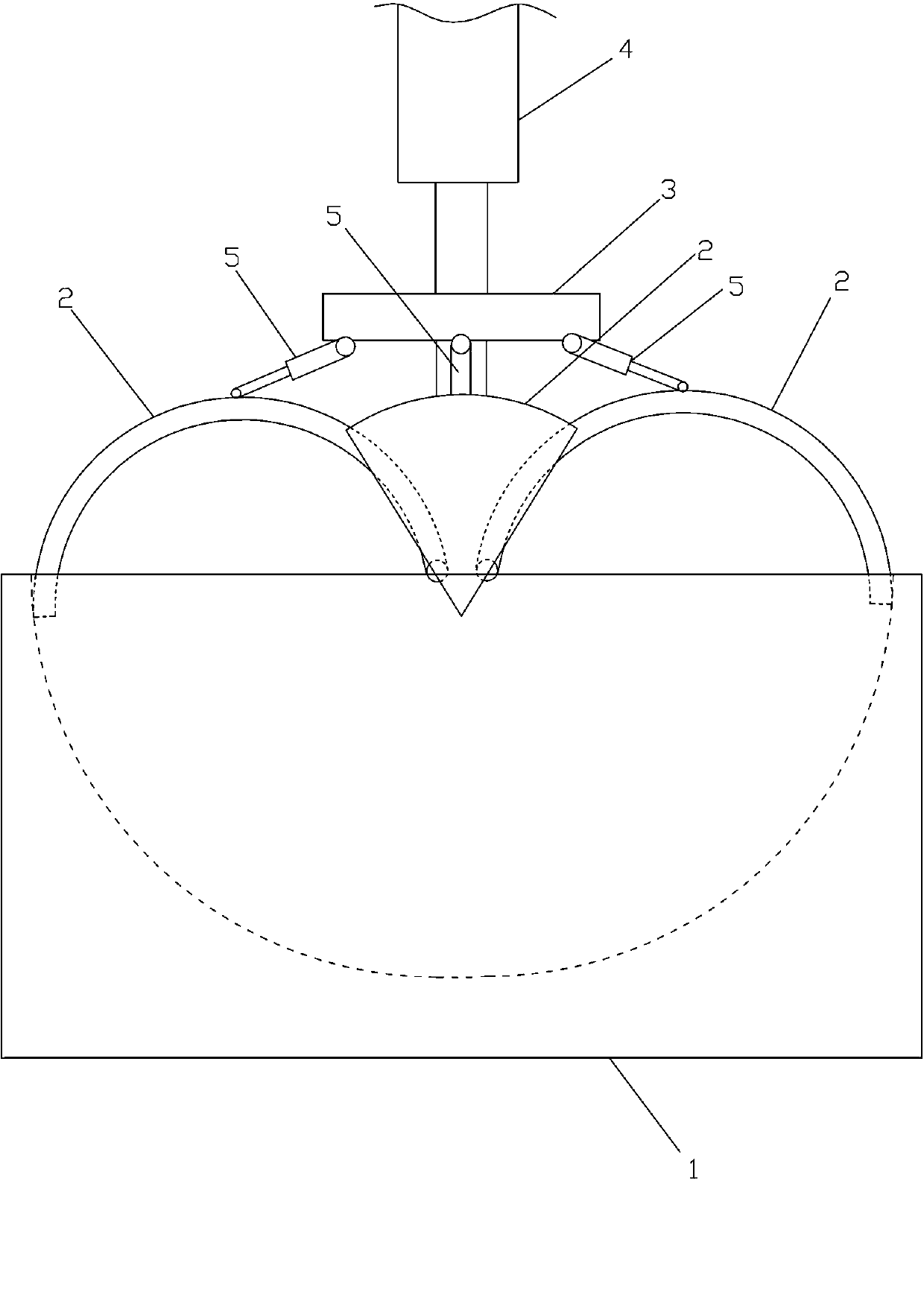

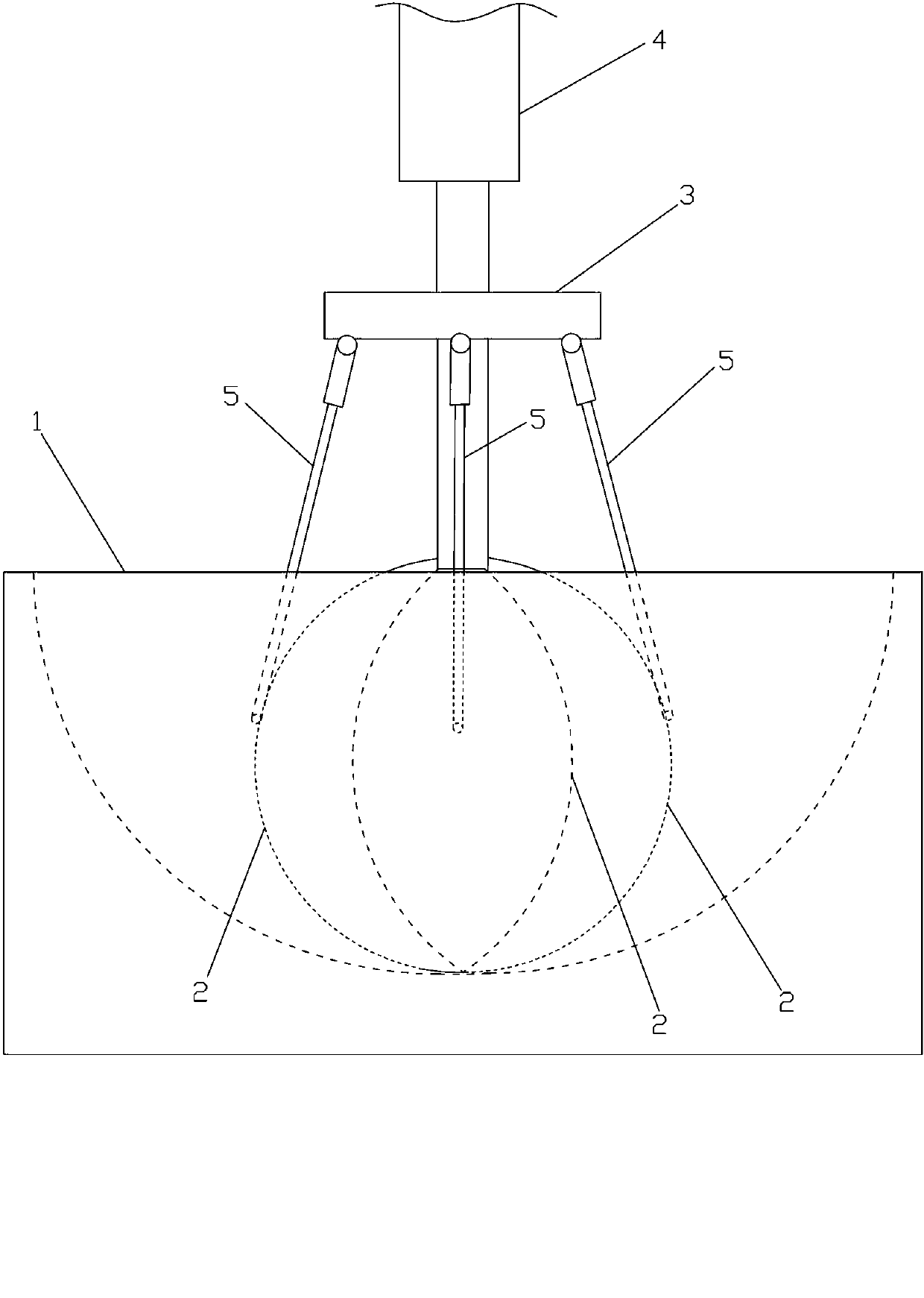

[0021] refer to figure 1 with figure 2 , an oolong tea kneading machine, comprising a kneading bucket 1 with an open upper end and a kneading device used in conjunction with the kneading bucket 1, the kneading device is arranged above the kneading bucket 1, and the kneading device includes four 1 / 4 kneading petals 2 , connecting seat 3, main cylinder 4 and 4 auxiliary cylinders 5, 4 1 / 4 kneading petals 2 can form a hollow spheroid after closing up. One end of the 4 auxiliary cylinders 5 is movably connected to the connecting seat 3, and the 4 auxiliary cylinders 5 surround the connecting seat 3, and the other ends of the 4 auxiliary cylinders 5 are movably connected to the back of the 1 / 4 kneading petal 2. When in use, 4 secondary cylinders 5 can drive the respective 1 / 4 kneading petals 2 to make opening / closing motions; the lower end of the main cylinder 4 is connected to the connecting seat 3, which can drive the connecting seat 3 to move up and down. Also refer to imag...

Embodiment 2

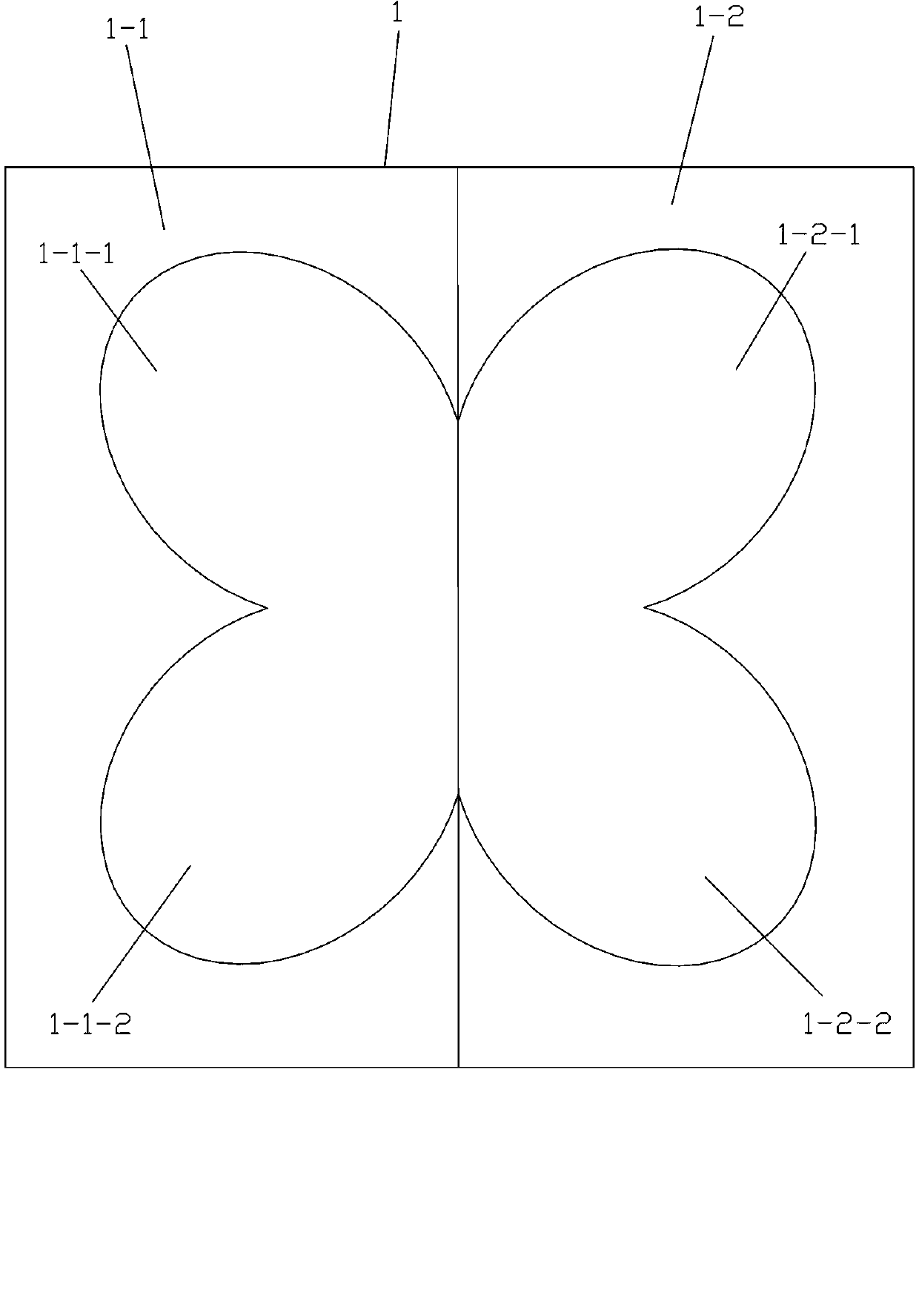

[0024] The structure and action process of this embodiment is basically similar to that of the first embodiment above, the main difference is that the kneading device includes three 1 / 3 kneading flaps (not shown in the figure), and the three 1 / 3 kneading flaps can be formed after being closed. A hollow sphere. Also refer to Figure 4 , the kneading barrel 1' is composed of detachable / closed left and right barrels 1-1', 1-2', and it consists of 3 sub-barrel areas 1-1-1', 1-1-2', 1- 1-3' composition, the inner surface of each bucket area 1-1-1', 1-1-2', 1-1-3' is adapted to the opening / closing track of 1 / 3 kneading flap.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com