Water mist sprayer

A fine water mist nozzle and fine water mist technology, which is applied in fire rescue and other directions, can solve the problems of increased fluid energy loss, increased manufacturing cost, and large energy loss of the nozzle, and achieves expanded fire extinguishing range, low manufacturing cost, and kinetic energy indicators Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

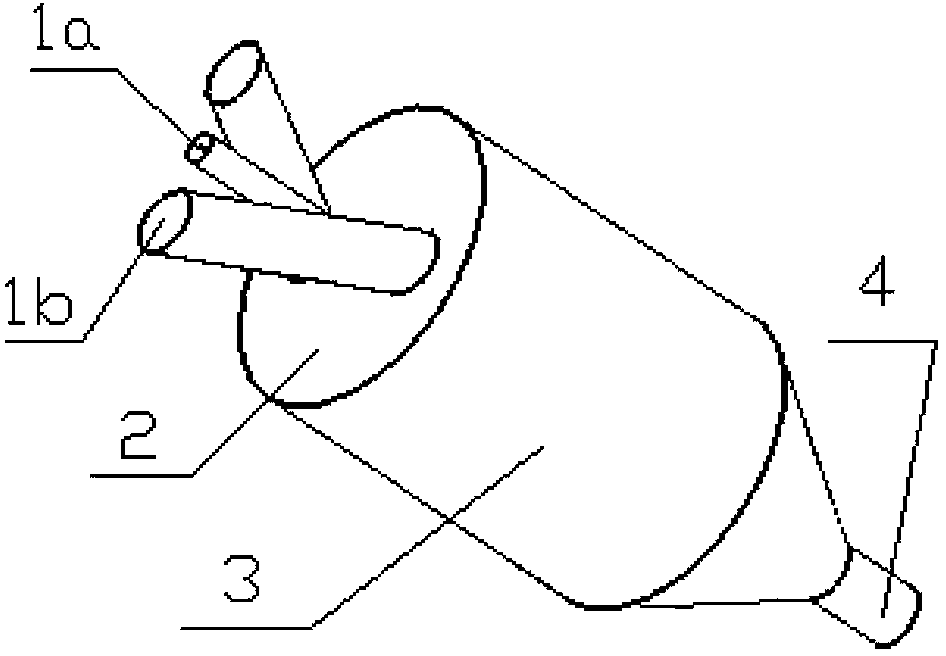

[0031] combine figure 1 . figure 1 It is a structural schematic diagram of the fluid flow field of the water inlet structure on both sides of the present invention. As shown in the figure, the fluid flow field structure of the water inlet structure on both sides of the figure is formed in the restriction of the structure. One end of the flow field structure is the central water inlet 1a and the side water inlet 1b. In this example, there are two side water inlets 1b; the middle part is the mixing chamber 3; the other end is the water outlet 4; figure 1 There are two side water inlets 1b arranged symmetrically on the radial plane 2 at one end of the mixing chamber 3, and 2 to 6 side water inlets 1b symmetrically arranged on the radial plane 2 of the mixing chamber 3.

[0032] Such as figure 1 As shown, the fine water mist nozzle includes a water inlet 1, a mixing chamber 3 and a water outlet 4, the water inlet 1 includes a central water inlet 1a and a side water inlet 1b, an...

Embodiment 2

[0043] combine Figure 2 to Figure 6 .

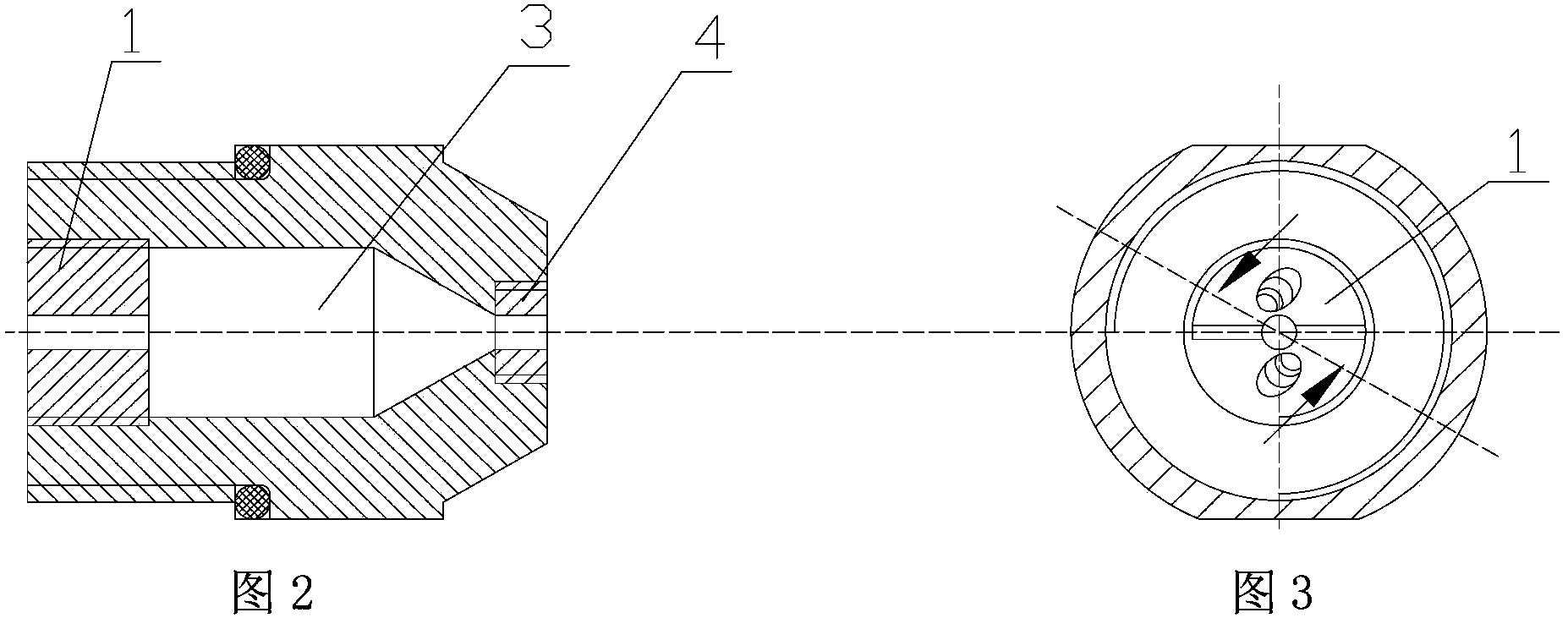

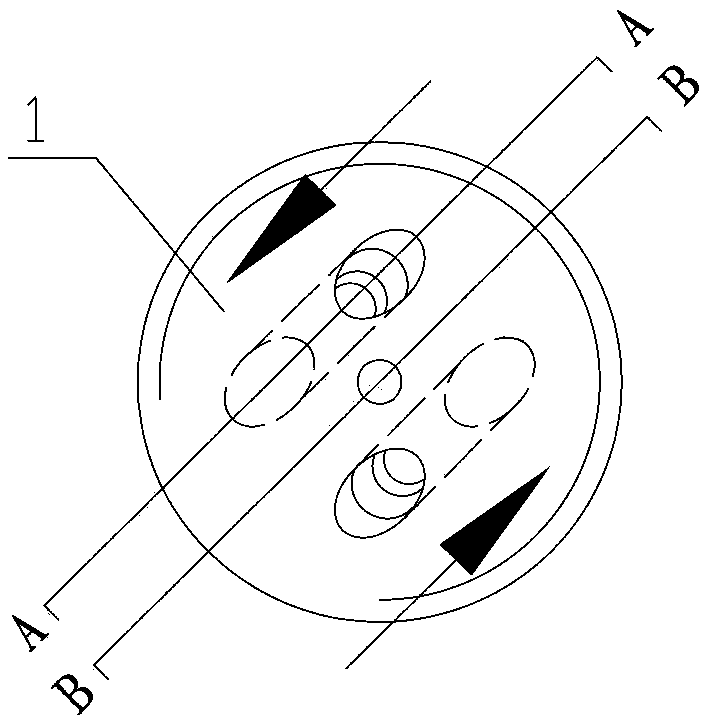

[0044] as the picture shows, figure 2 It is a schematic cross-sectional view of a structure using the nozzle of the present invention, image 3 yes figure 2 Schematic diagram of the inlet end face structure, Figure 4 It is a structural schematic diagram of the water inlet of the nozzle adopting the present invention, Figure 5 yes Figure 4 Schematic diagram of BB section structure, Figure 6 yes Figure 4 Schematic diagram of the cross-sectional structure of AA. This example is formed by combining the structure of each component figure 1 Fine water mist nozzle with fluid flow field structure.

[0045] Such as figure 2As shown, the spray head includes a nozzle assembly constituting the nozzle outlet 4 , a water inlet assembly constituting the water inlet 1 , and a cavity assembly forming the mixing chamber 3 together with the nozzle assembly and the water inlet assembly. The nozzle assembly, the water inlet assembly and t...

Embodiment 3

[0049] The present invention adopts FLUNET flow analysis software to carry out numerical simulation analysis on the internal and external jet flow field of the structure fine water mist fire extinguishing nozzle of the present invention, predict and analyze the atomization performance of the nozzle from the internal and external jet flow field of the nozzle, and the structural parameters have an impact on the atomization performance of the nozzle A comparative analysis of the influencing factors was carried out. Through the experimental optimization of the central inlet channel 1a (size 1, 1.5, 2mm) of the inlet and the side inlet channel 1b (size 1, 1.5, 2mm) of the outlet 4 (size 1.2, 1.6, 2mm), the fine The structure of the water mist nozzle. And the atomization performance and fire extinguishing effect of the structure fine water mist nozzle of the present invention were tested.

[0050] The main contents of the atomization performance test of the nozzle: the atomization a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com