A method and device for preparing a thin film by electrostatic gas spray thermal curing

An electrostatic atomization and thermal curing technology, which is applied in the direction of electrostatic spraying device, spray discharge device, spraying device, etc., can solve the problems of low raw material utilization rate of film and substrate bonding, limited film preparation efficiency, and small liquid flow rate, etc., to achieve Improve the effect of atomization, wide applicability, and improve uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The embodiments of the present invention are described in detail below. This embodiment is implemented under the premise of the technical solution of the present invention, and detailed implementation methods and specific operation processes are provided, but the protection scope of the present invention is not limited to the following embodiments. .

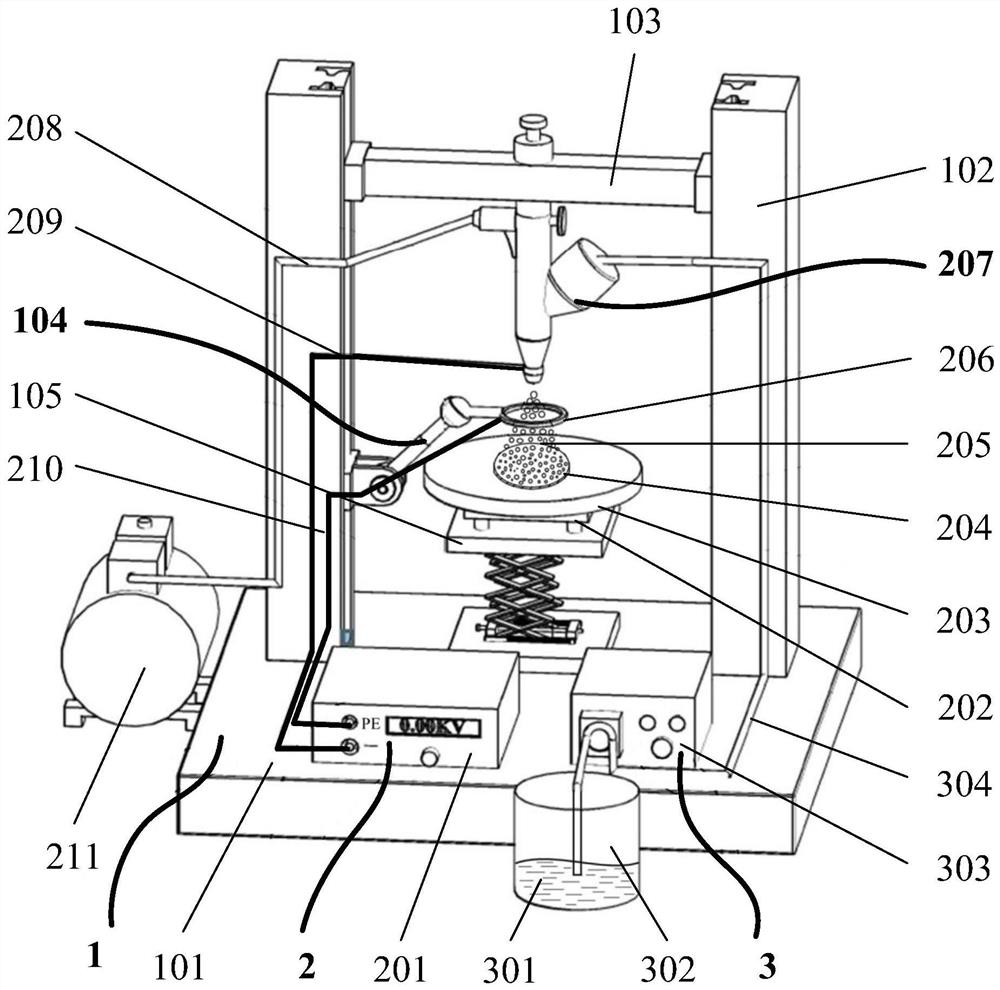

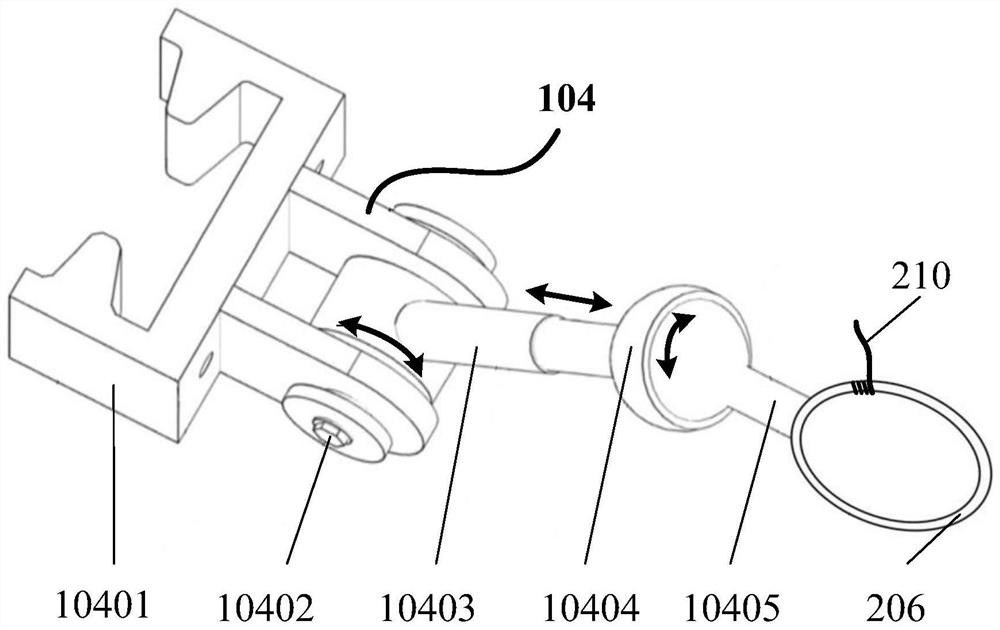

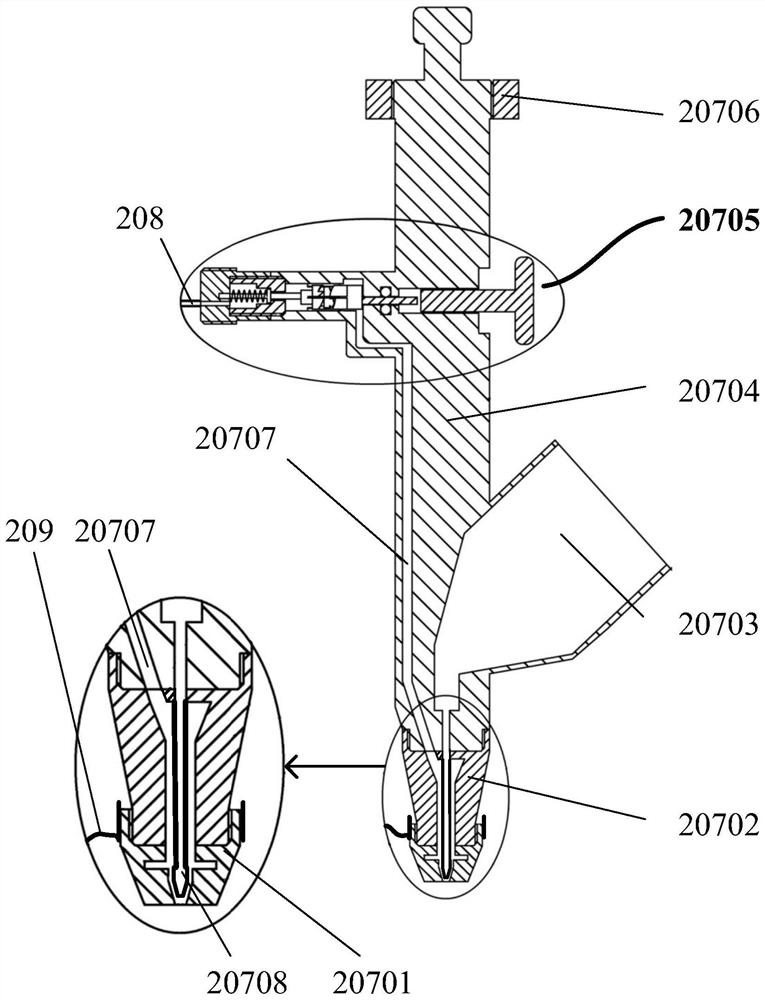

[0040]The method for preparing a thin film by electrostatic gas spray thermosetting includes a moving support platform 1 , an electrostatic atomization auxiliary system 2 , and a liquid supply system 3 . The moving support platform 1 includes a base platform 101 , a support frame 102 , a beam 103 , a ring electrode adjustment mechanism 104 , and a lifting platform 105 . A beam 103 and a ring electrode adjustment mechanism 104 are installed on the support frame 102, and the beam 103 and the ring electrode adjustment mechanism 104 can translate up and down along the slide rail. The ring electrode adjustment mechanism 104 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com