Hard carbon black shaft end raw material oil gun

A technology of hard carbon black and raw material oil, which is applied in the field of oil guns and hard carbon black shaft-end raw material oil guns. The effect of increasing the cross-sectional area, increasing the atomization angle, and improving the yield of carbon black

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

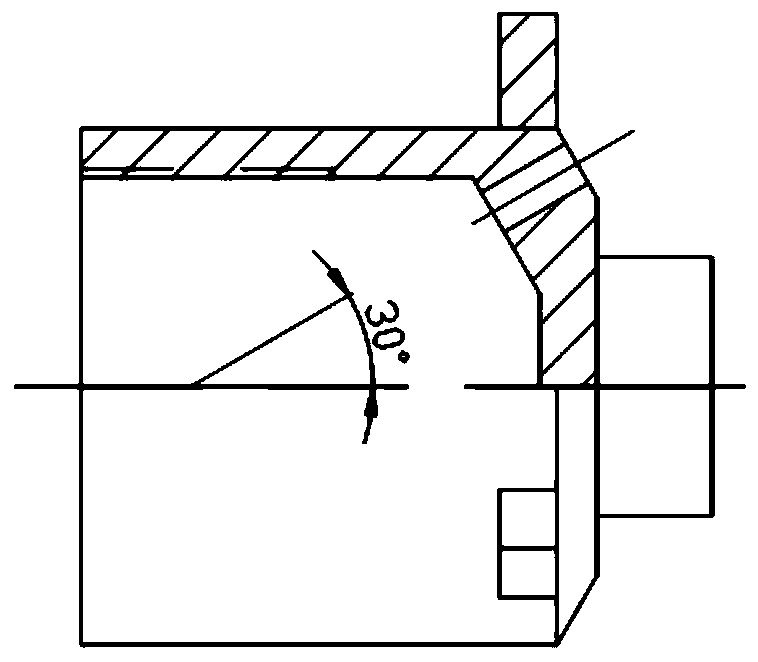

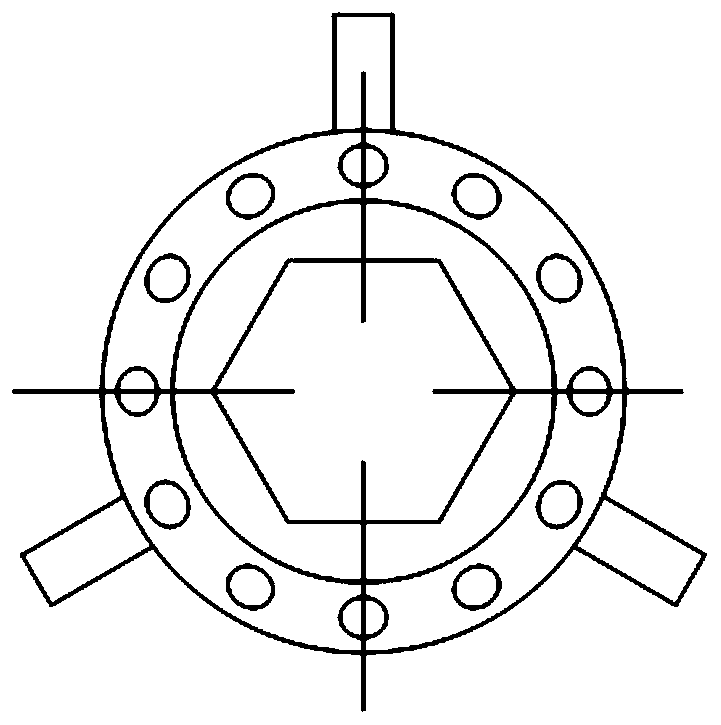

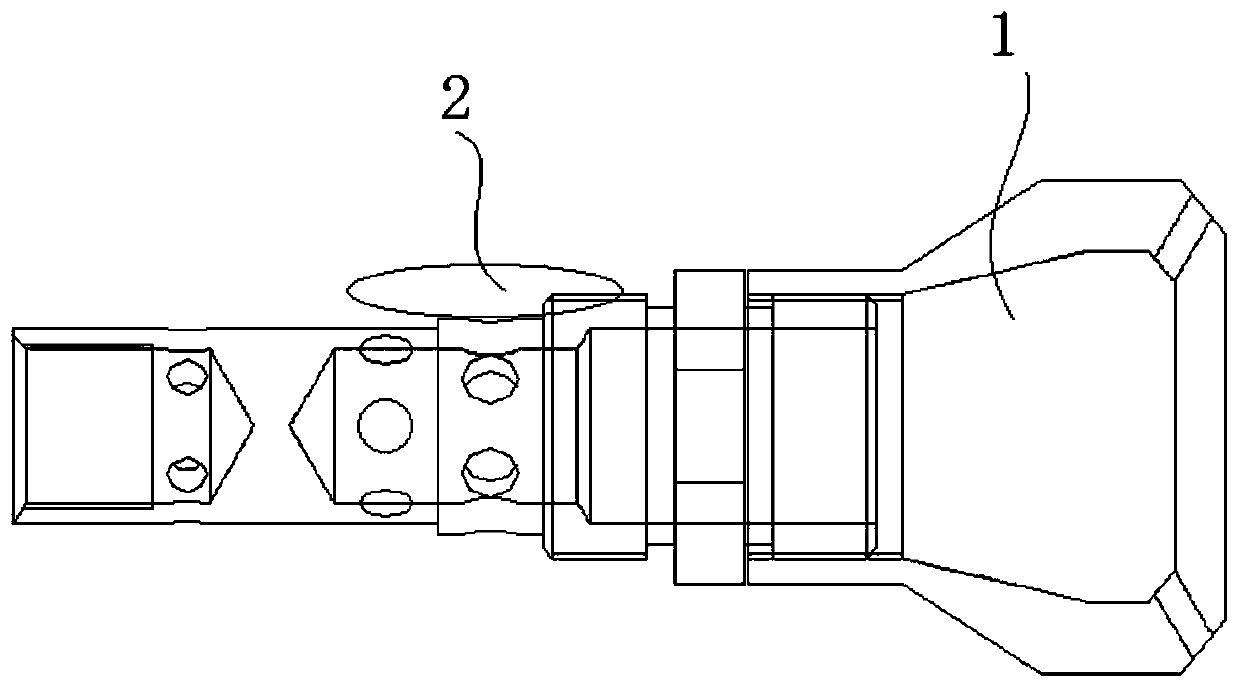

[0030] like Figure 3-11 Shown, the present invention works and implements like this, a kind of hard carbon black shaft end raw material oil gun mainly is made up of gun head 1 and gun body 2; It is characterized in that: gun head 1 and gun body 2 can be separated, Through threaded connection; the gun head 1 has a built-in blind hole 3, and the gun head 1 and the blind hole 3 are integrally formed in a two-stage structure, wherein the rear end part is a section of equal-diameter cylinder, with a built-in internal thread 4, and the gun The outer thread of the body is connected by a closed thread; the other section is the front end part of the gun head 1, and the front end part extends forward from the front end part of the internal thread and gradually increases in size and forms a blind hole chamber 5 on the closed end face of the front end of the gun head shell. Part of it is a mixing chamber for raw oil and compressed air, and the raw oil and compressed air are fully mixed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com