Dry-state preservation method for ultra-filtration membrane component

A preservation method and ultrafiltration membrane technology, which is applied to the preservation of ultrafiltration membrane modules, aiming at the field of dry preservation of ultrafiltration membrane modules, can solve the problem that cannot meet the needs of safe storage and convenient transportation of ultrafiltration membrane modules at the same time, and the material of ultrafiltration membranes Strict requirements, cumbersome handling and other issues, to achieve the effect of reducing transportation difficulty, low cost, and convenient cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment ( 1

[0023] The invention discloses a method for storing ultrafiltration membrane components in a dry state. The ultrafiltration membrane components to be preserved are made of internal pressure polysulfone material and have a molecular weight cut-off of 67,000. at water temperature 25 o C. Under the operating pressure of 0.1MPa, the ultrafiltration water flux is 150LMH (liter / square meter / hour).

[0024] Before packaging after production, install the ultrafiltration membrane module on a small ultrafiltration equipment, configure a sufficient amount of sodium hypochlorite sterilizing solution with a concentration of 100ppm (calculated as available chlorine), and run it at room temperature for 5 minutes at an operating pressure of 0.1MPa , to sterilize the components.

[0025] Use ultrafiltration water to fully clean the ultrafiltration membrane module at room temperature, and operate at a pressure of 0.1 MPa for 2 hours.

[0026] Remove the ultrafiltration membrane assembly from ...

Embodiment ( 2

[0031] Embodiment (two) ~ (four):

Embodiment

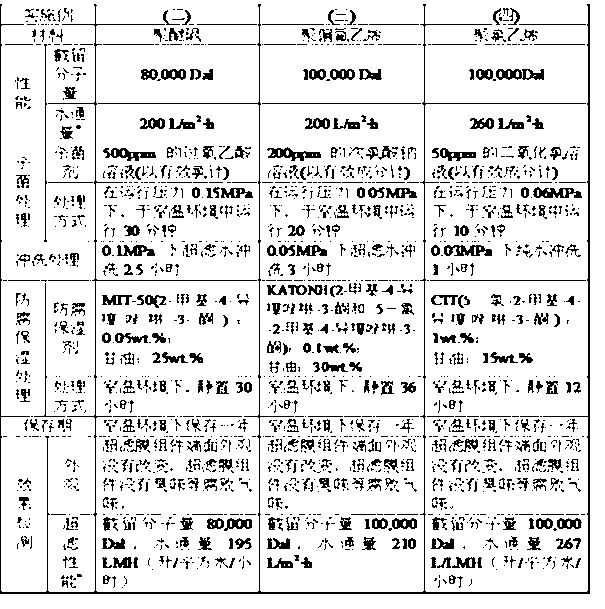

[0032] Embodiments (2), (3), and (4) Refer to Embodiment (1) for actual operation, and refer to Table 1 for specific details, as follows.

[0033] Table 1 Implementation parameters of ultrafiltration membrane module dry membrane preservation method

[0034]

[0035] Note*: at water temperature 25 o C, under the operating pressure of 0.1MPa, the ultra-filtered water is used for detection.

[0036] After the ultrafiltration membrane module is operated with the above parameters, the ultrafiltration performance has not changed after testing. The ultrafilter is effectively preserved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com