Device and method for intelligently metering and monitoring blending process for mixing plant

A technology of mixing equipment and monitoring device, applied in mixer accessories, chemical instruments and methods, dissolution and other directions, can solve the problems of insufficient supervision, difficult data accuracy, and insufficient data collection accuracy, saving manpower and material resources, and applicability. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

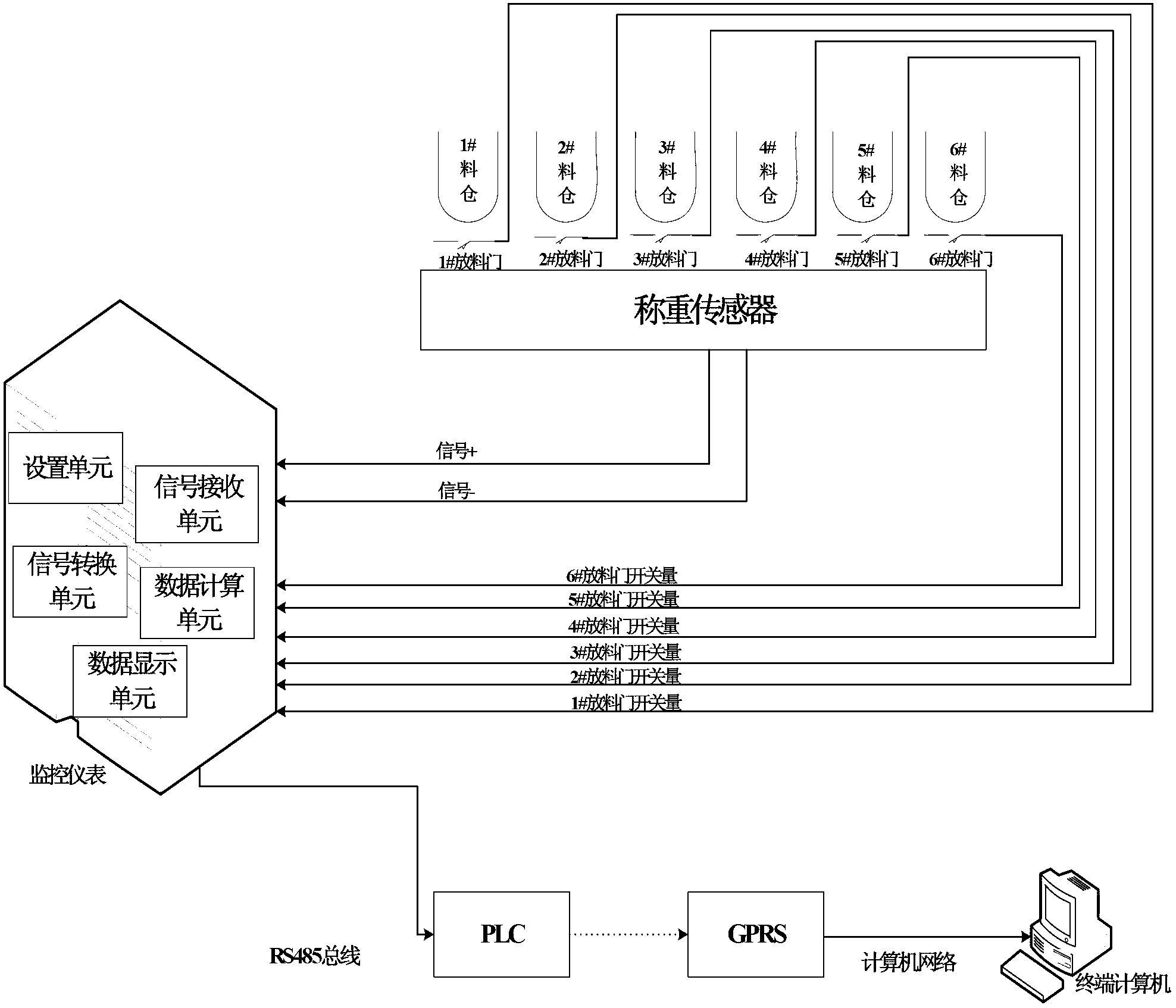

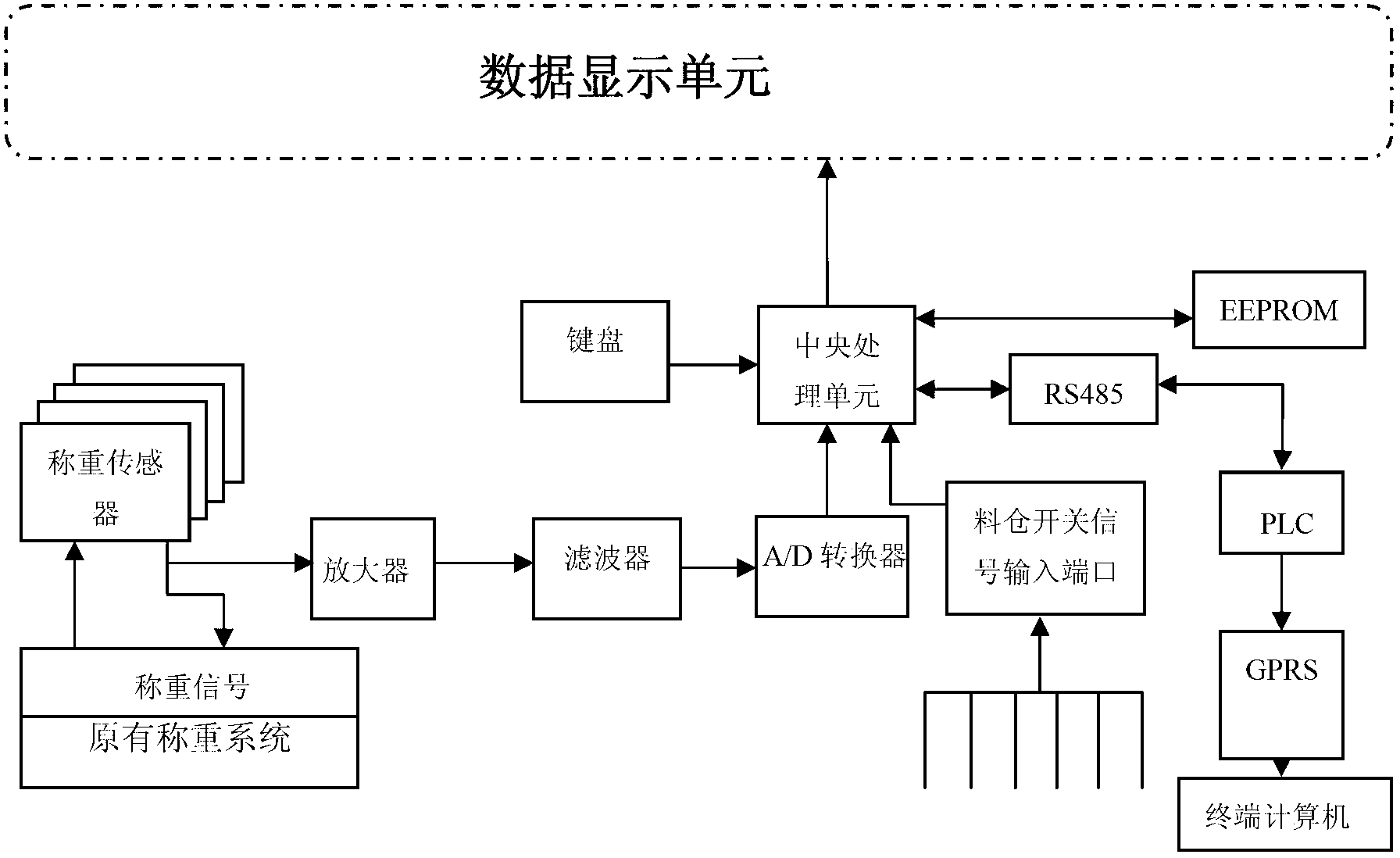

[0038] Such as figure 1 As shown, the model selected for the load cell is: LB5000 mixing equipment; the model selected for the monitoring instrument is: SINYDb001; the model selected for PLC and EEPROM is: S7-200 224XPCN; the selected model for the monitoring system is: intelligent data monitoring system; A / The model selected by the D converter is EM231; the model selected by the signal receiving unit is: SINYD-js012; the model selected by the central processing unit is: SINYD-cl022, the model selected by the amplifier is CF-02 The model selected by the filter is: SINYD- lb032.

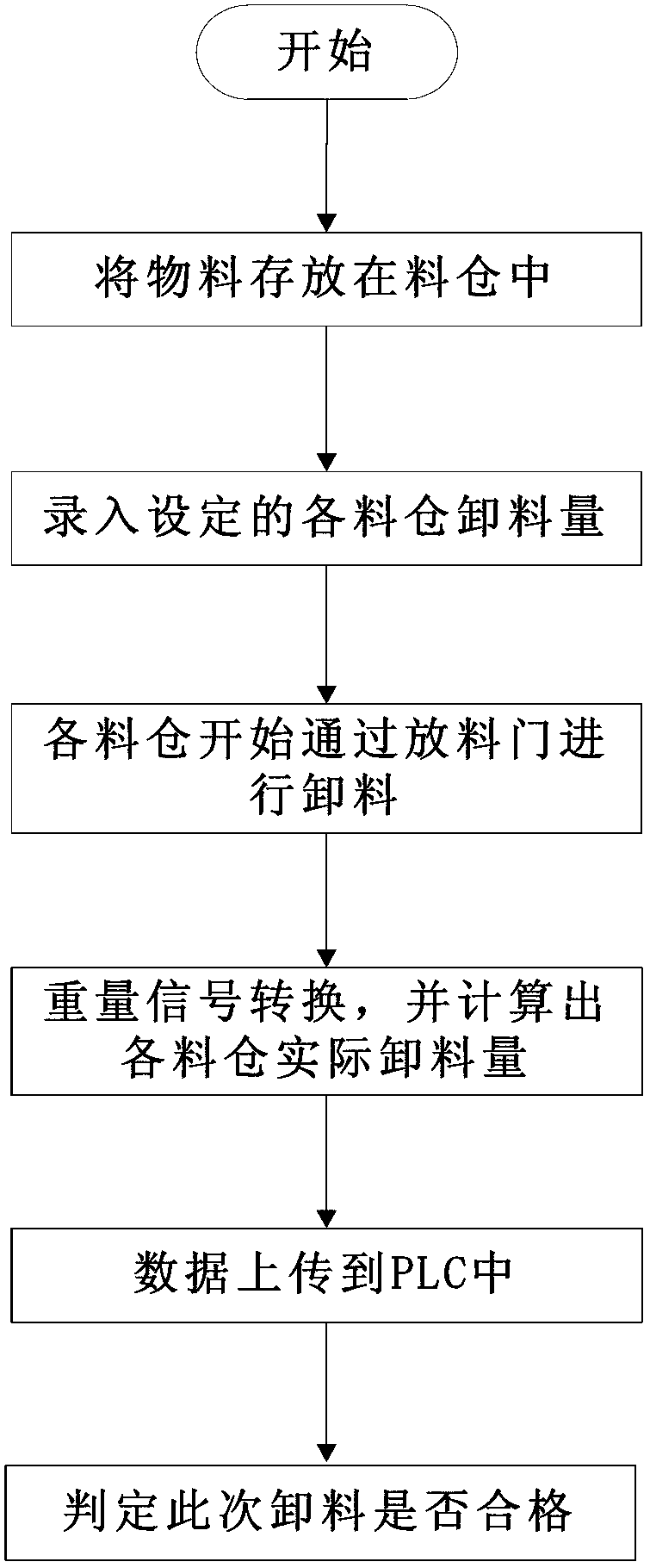

[0039] The discharge door of each silo is connected to the monitoring instrument through a signal line, and a load cell is installed under the silo. The load cell is connected to the monitoring instrument through two signal lines, and the monitoring instrument is connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com