Novel steel rust removing device and rust removing method of steel

A new type of technology for steel, applied in the field of machinery, can solve the problems of steel surface damage, high labor intensity, low efficiency, etc., and achieve the effects of improving corrosion resistance and durability, improving coating adhesion, and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

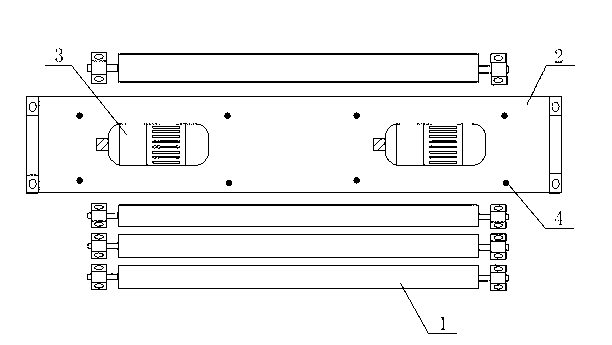

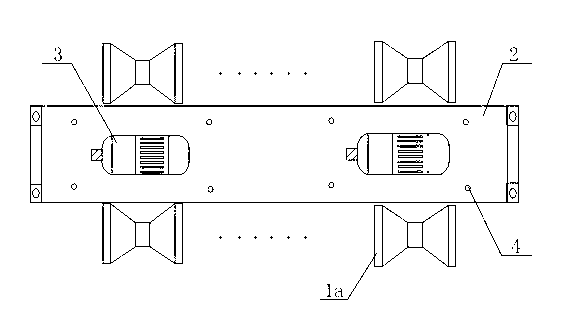

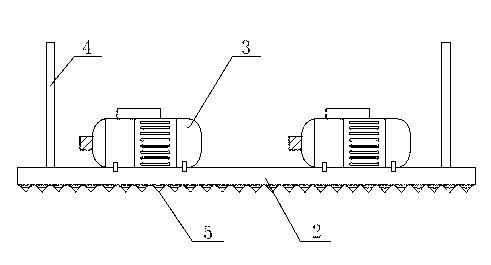

[0017] Below in conjunction with accompanying drawing, the present invention will be further described:

[0018] The new steel derusting device includes a roller table, a derusting plate 2 and a vibrator 3 arranged above the derusting plate. There is a gap between them. According to the difference of the rust-removing steel, the gap between the rust-removing plate and the steel to be derusted is also different. Two vibrators are symmetrically arranged above the rust-removing plate to provide a vibration source for the rust-removing plate; rust-removing plate 2 It is made of FRP sheet with sharp corners, and the sharp corners 5 are set under the rust removal plate 2. If the density is too high, the volume of the sharp corners will become smaller, and the strength and rigidity will be reduced, which will affect durability. If the density is too small, a single If the distance between sharp corners is too large, the rust removal zone cannot cover the steel, resulting in the inabi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com