Single-station welding and dust exhausting device

A kind of dust removal equipment and single-station technology, which is applied in the direction of dust removal, welding accessories, and separation of dispersed particles. It can solve the problems of personal injury, dust and smoke pollution, and expensive dust removal equipment, so as to ensure the dust removal effect and be easy. Replacement, to avoid the effect of self-weight sagging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

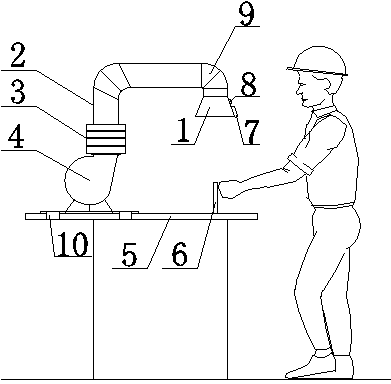

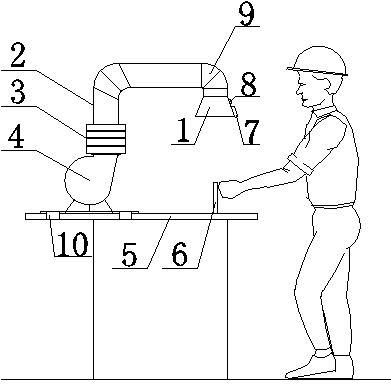

[0020] Combine below figure 1 , the present invention is further described:

[0021] Reversely install the impeller of the exhaust fan 4 to ensure that the wind direction of the exhaust fan is reversed, and then fix the exhaust fan 4 on the base surface 5 of the welding fixture through the fastening bolt 10. In order to ensure that there is still an effective welding process space, the exhaust fan should be made 4 Install to one side.

[0022] The spring tube 9 is connected with the dust return pipe 2 as a whole, so that the dust return air outlet 1 can rotate freely, which is convenient for employees to operate. At the same time, it can ensure that the dust return air outlet 1 maintains a stable posture and avoids sagging due to its own weight.

[0023] The four corners of the active filter cotton storage box 3 are fixedly connected to the air return port of the exhaust fan 4 itself by bolts; the dust return pipe 2 is also fixed on the four corners of the active filter cott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com