Titanium alloy seamless pipe with variable wall thickness as well as radial forging and forming mechanism and method of titanium alloy seamless pipe

A variable-wall-thickness tube and radial forging technology, which is applied in the manufacture of tools, transportation and packaging, and metal processing equipment, can solve the problems of small deformation in each pass, low plasticity of titanium alloys, and complex processing methods frame weight, good surface quality, and high dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

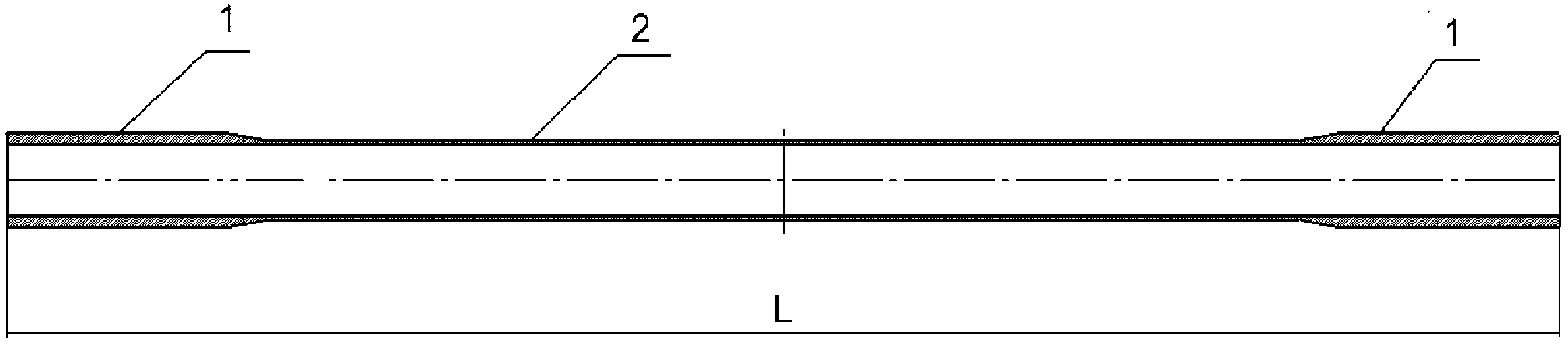

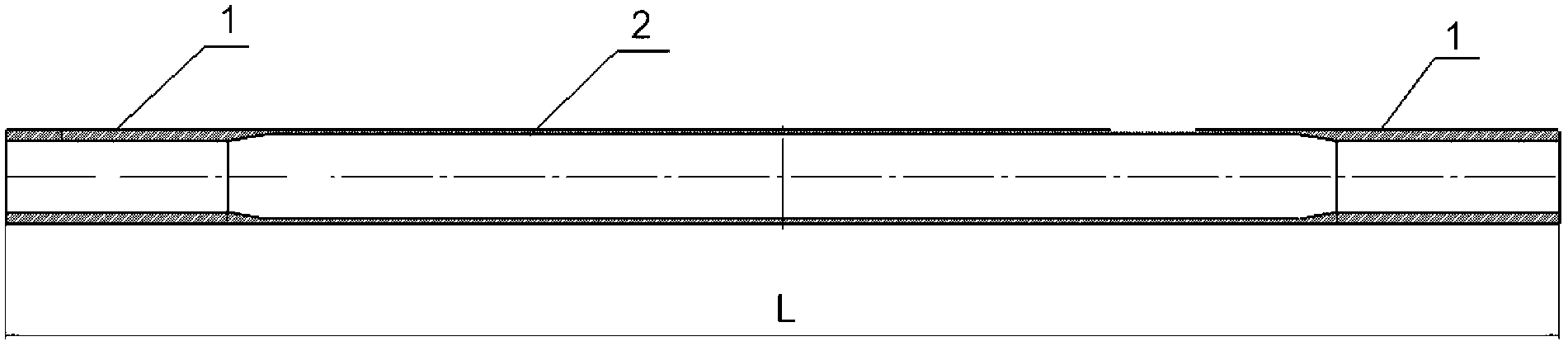

[0023] Example 1 Preparation of titanium alloy tube TA18 with equal inner diameter and two-stage unequal wall tube

[0024] Use titanium alloy tube blank (φ42mm×2mm inner diameter φ38mm), first open the radial forging forming mechanism, put the thin-walled part 2 of the prepared tube body into the mold in advance, and insert the mandrel 4 (φ37.8mm) into the inside of the tube (The outer diameter of the mandrel rod and the inner diameter of the pipe are a clearance fit), and then the radial forging forming mechanism mold 3 is opened, so that the mold 3 plastically deforms the pipe wall along the radial direction of the pipe body, so that the wall thickness of the pipe body is thinned while extending along the axial direction. elongation, and the thick-walled part 1 of the pipe body does not participate in the forming. When the wall thickness of the thin-walled part 2 of the pipe body reaches 0.9mm, open the radial forging forming mechanism mold 3, take out the deformed pipe bod...

Embodiment 2

[0025] The preparation of the two-stage unequal wall tube TA2 of embodiment dititanium alloy inner diameter is equal

[0026] The method refers to the first embodiment, the difference is that the titanium alloy tube blank is changed to φ63mm×2.5mm, the inner diameter is φ58mm, and the mandrel 4 is changed to φ57.8mm.

Embodiment 3

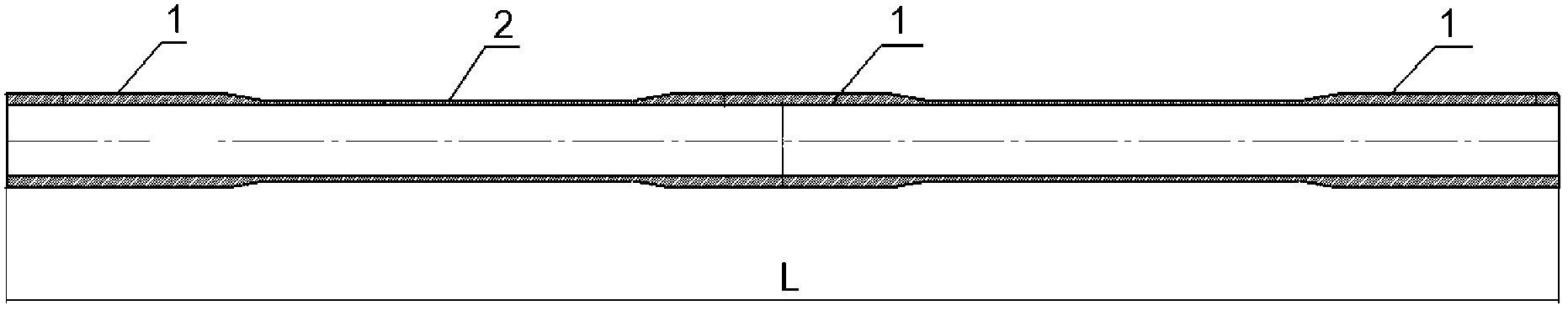

[0027] Example 3 Preparation of titanium alloy inner diameter equal two-stage unequal wall tube TC4

[0028] The method refers to Example 1, the difference is that the titanium alloy tube blank is changed to φ22mm×1.5mm, the inner diameter is φ19mm, and the mandrel 4 is changed to φ18.8mm. At the same time, in order to improve the plasticity and pass processing rate of the material, the During the forging process, the titanium alloy tube billet and mandrel are heated at a temperature of 600°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com