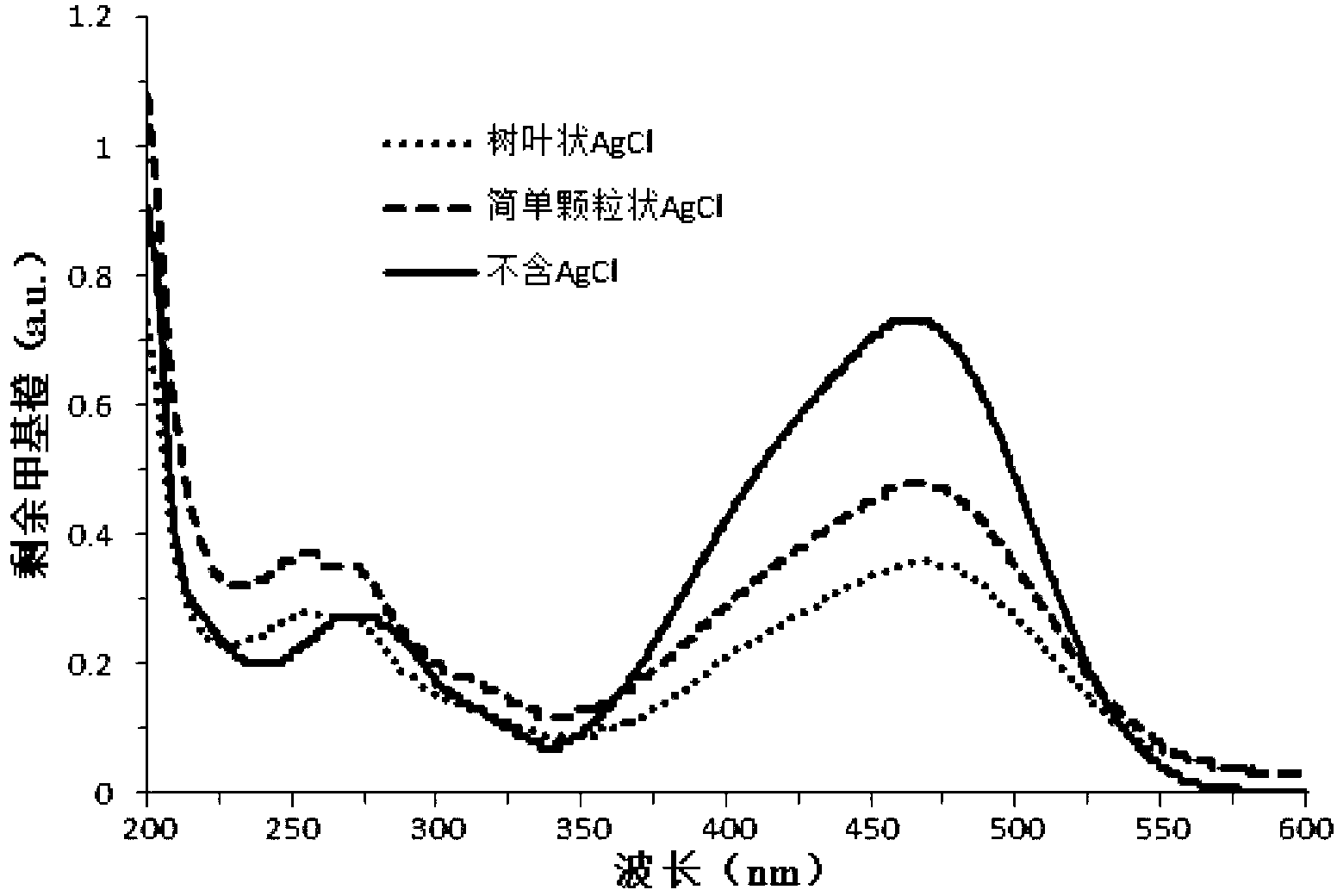

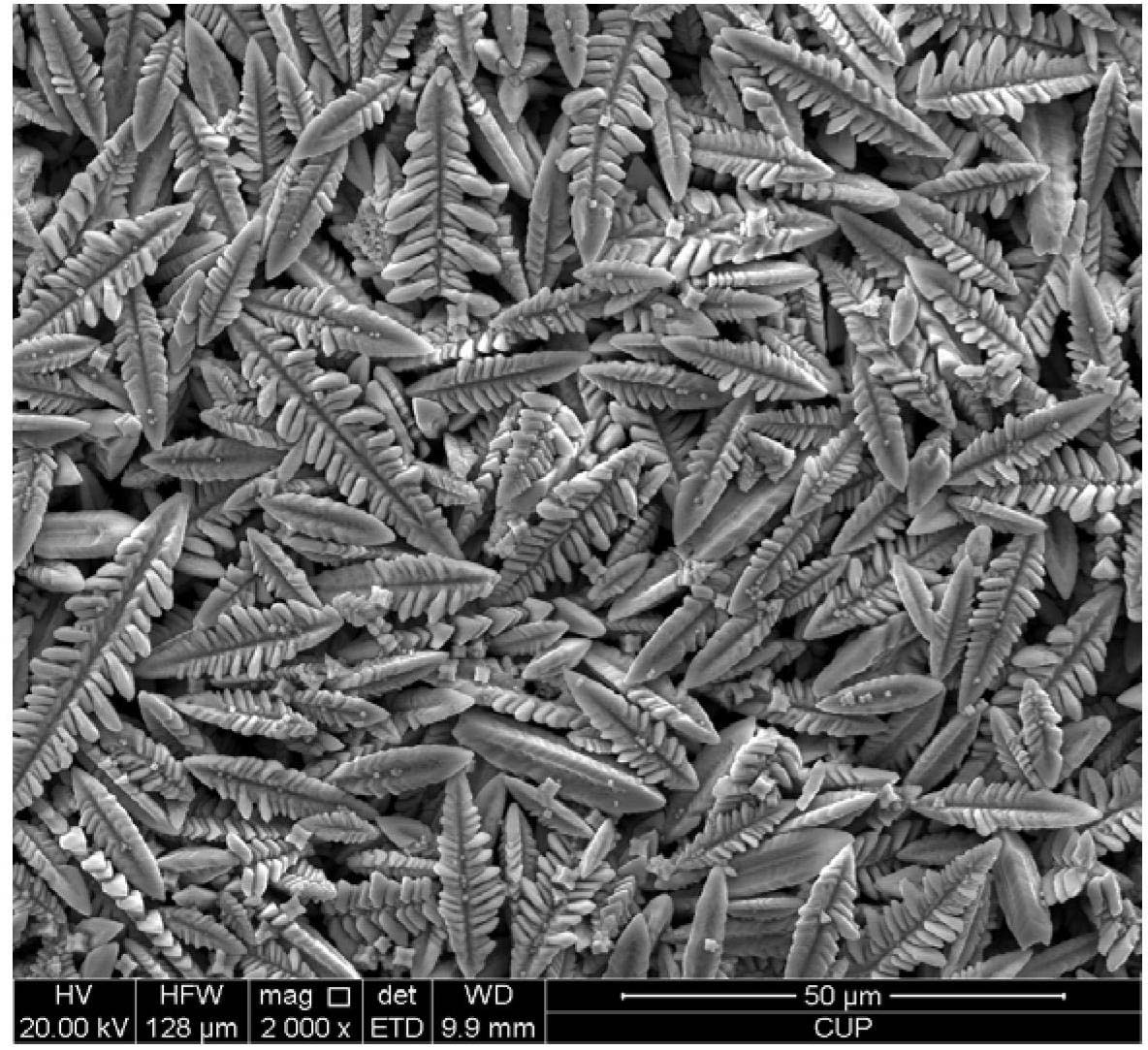

Preparation method for leaf-shaped silver chloride particle with micron structure

A micro-structure, silver chloride technology, applied in chemical instruments and methods, silver halide, chemical/physical processes, etc., can solve the problems of high-performance AgCl material constraints, achieve good photocatalytic performance, enhance stability, step simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Weigh 0.0016 g FeCl with an electronic balance 3 , 0.0170 g AgNO 3 In two dry beakers, weigh 0.0670 g of PVP and place in FeCl 3 Use a graduated cylinder to measure a part of 3 ml concentrated HCl and two parts of EG solution, marked as EG1 and EG2 respectively, wherein the volume of EG1 solution is 7 ml, and the volume of EG2 solution is 10 ml.

[0019] loaded with FeCl 3 Pour the EG2 solution into the beaker of PVP, stir roughly with a glass rod and then place it on a magnetic stirrer until FeCl 3 and PVP are uniformly dispersed in EG, and the solution is yellow at this time. Pour the EG1 solution into the AgNO 3 in a beaker, stirred roughly with a glass rod and placed on a magnetic stirrer until AgNO 3 Evenly dispersed in EG, the solution is a colorless transparent liquid at this time. Under magnetic stirring, the colorless and transparent AgNO 3 The solution was evenly added dropwise to the yellow FeCl 3 and PVP mixed solution, after stirring for 1 min, add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com