Method for producing slag portland cement by basalt in ingredients of cement

A Portland cement and basalt technology, applied in cement production and other directions, can solve the problems of low admixture content, low early strength, and high clinker consumption, and achieve increased economic benefits, increased output, and improved cement quality assurance coefficient. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

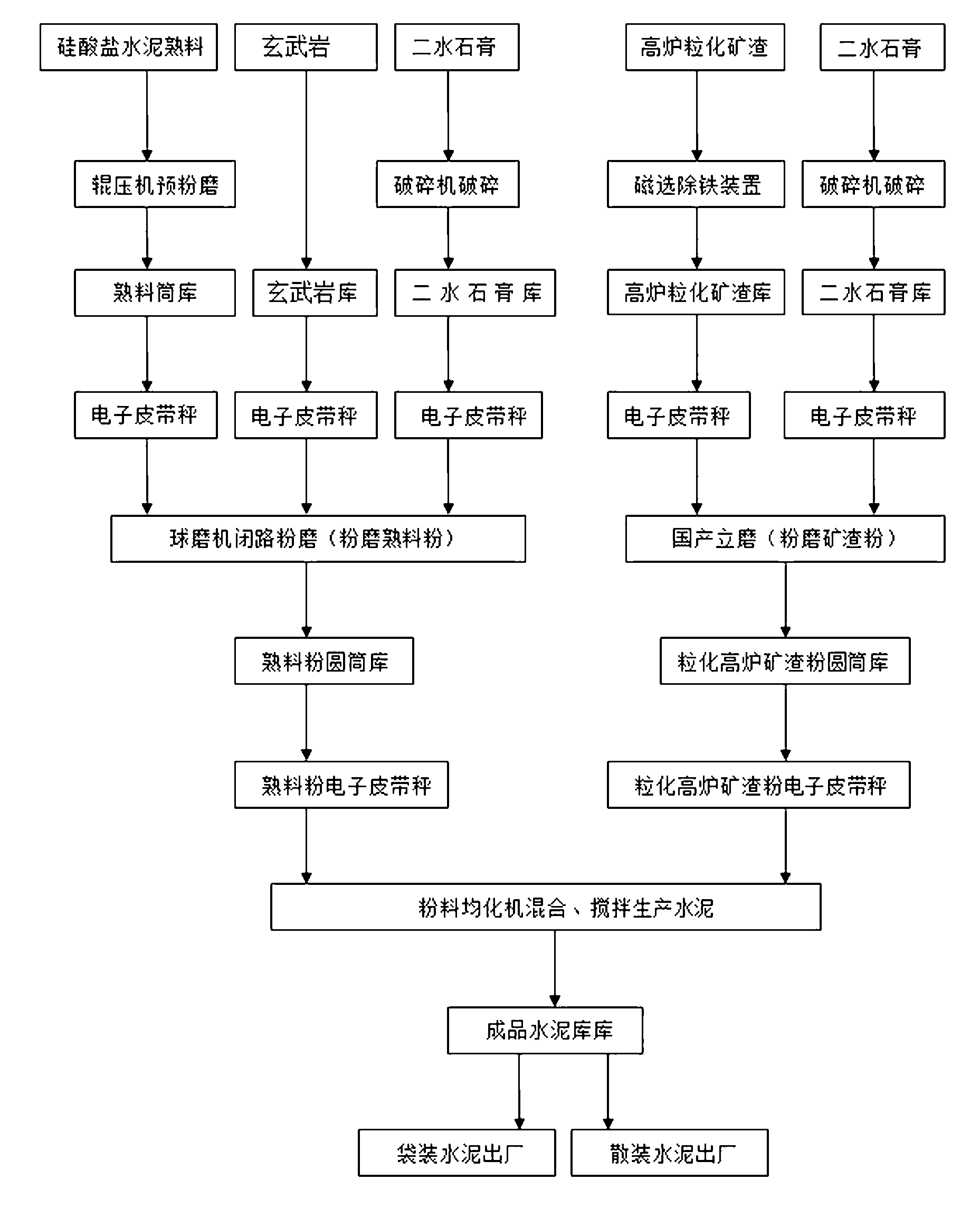

Method used

Image

Examples

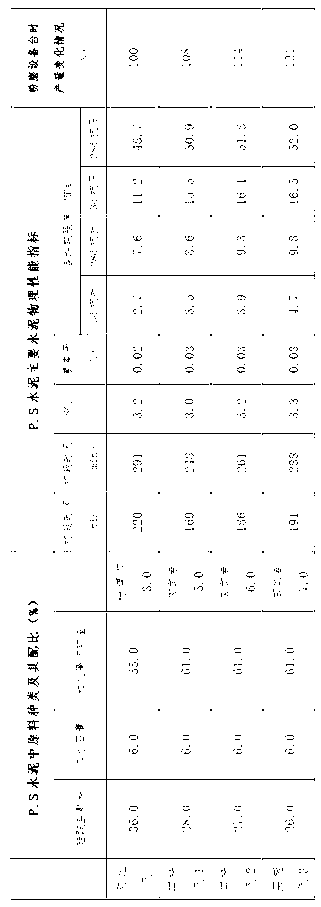

Embodiment 1

[0028] Example 1: The weight percentage of each raw material in slag Portland cement is 5-7% of basalt, 26-28% of Portland cement clinker powder, 6% of dihydrate gypsum, and 61% of granulated blast furnace slag powder.

[0029] Proceed as follows:

[0030] A. Grinding portland cement clinker, dihydrate gypsum and basalt with large roller press and ball mill to produce clinker powder,

[0031] The weight percentage of raw materials is basalt 14.3%, clinker 80%, dihydrate gypsum 2.1%;

[0032] B. Grinding granulated blast furnace slag and dihydrate gypsum with a slag vertical mill to produce fine slag powder. The weight percentage of raw materials is 93.8% of granulated blast furnace slag and 3.9% dihydrate gypsum.

[0033] C. Mix and stir clinker powder with a weight percentage of 35% and fine slag powder with a weight percentage of 65% by a mixing homogenizer to obtain slag portland cement.

Embodiment 2

[0034] Example 2: The weight percentage of each raw material in slag portland cement is : Basalt 6.0% , clinker 27.0%, dihydrate gypsum 6.0%, granulated blast furnace slag powder 61.0%.

[0035] Proceed as follows:

[0036] A. Grinding portland cement clinker, dihydrate gypsum and basalt with large roller press and ball mill to produce clinker powder,

[0037] The weight percentage of raw materials is basalt 17.1%, clinker 77.1%, dihydrate gypsum 2.1%;

[0038] B. Grinding granulated blast furnace slag and dihydrate gypsum with a slag vertical mill to produce fine slag powder. The weight percentage of raw materials is 93.8% of granulated blast furnace slag and 3.9% dihydrate gypsum.

[0039] C. Mix and stir clinker powder with a weight percentage of 35% and fine slag powder with a weight percentage of 65% by a mixing homogenizer to obtain slag portland cement.

Embodiment 3

[0040] Example 3: The percentage by weight of each raw material in the slag Portland cement is: basalt 7.0%, clinker 26.0%, dihydrate gypsum 6.0%, granulated blast furnace slag powder 61.0%.

[0041] Proceed as follows:

[0042] A. Grinding portland cement clinker, dihydrate gypsum and basalt with large roller press and ball mill to produce clinker powder,

[0043] The weight percentage of raw materials is basalt 20.0%, clinker 74.3%, dihydrate gypsum 2.1%;

[0044] B. Grinding granulated blast furnace slag and dihydrate gypsum with a slag vertical mill to produce fine slag powder. The weight percentage of raw materials is 93.8% of granulated blast furnace slag and 3.9% dihydrate gypsum.

[0045] C. Mix and stir clinker powder with a weight percentage of 35% and fine slag powder with a weight percentage of 65% by a mixing homogenizer to obtain slag portland cement.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| activation index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com