Calcination production line and calcination method for industrial by-product gypsum

A technology of industrial by-product gypsum and production line, which is applied in the calcination production line of industrial by-product gypsum and in the field of industrial by-product gypsum calcination. To the atmosphere, the quality of finished products is stable, and the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

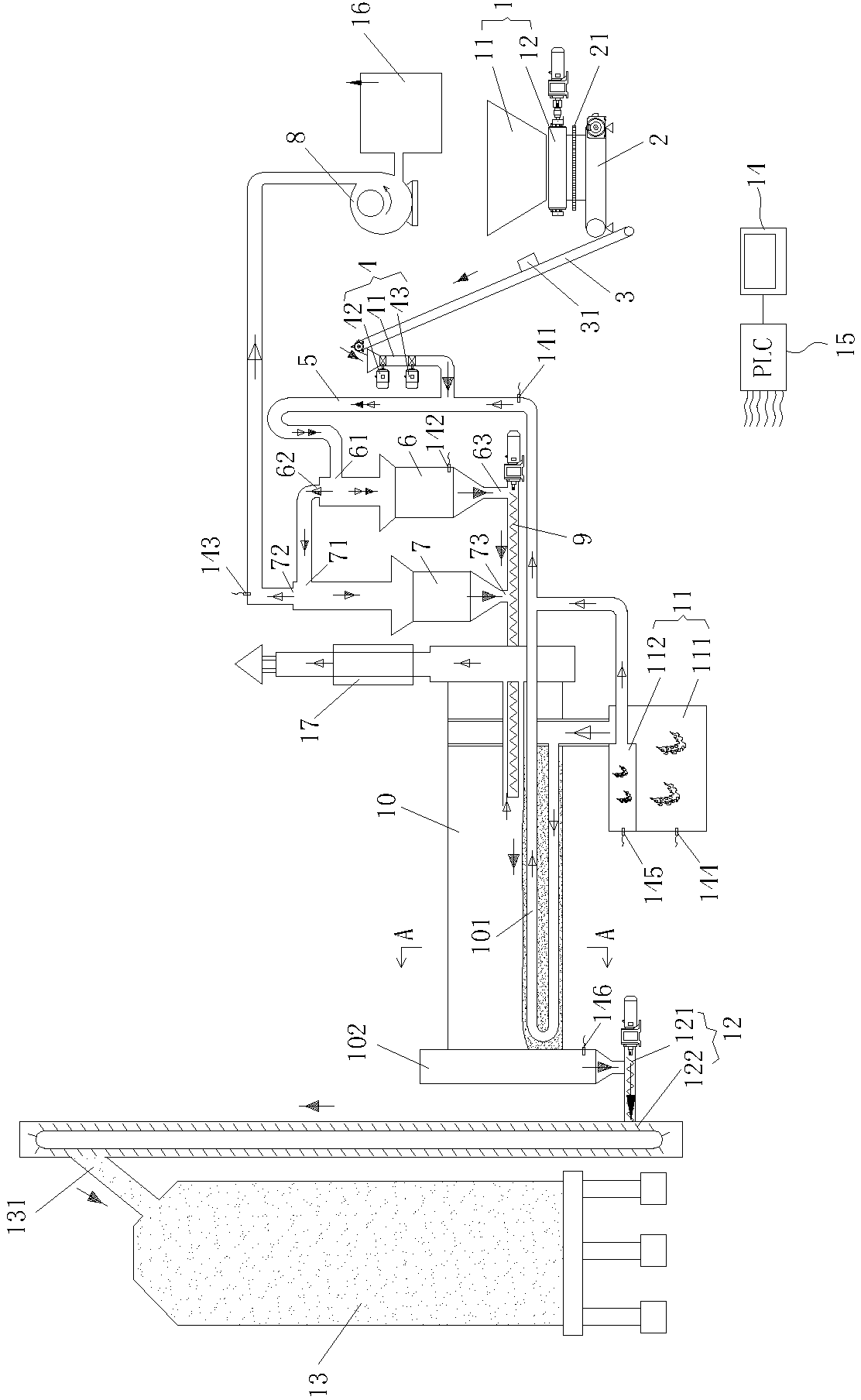

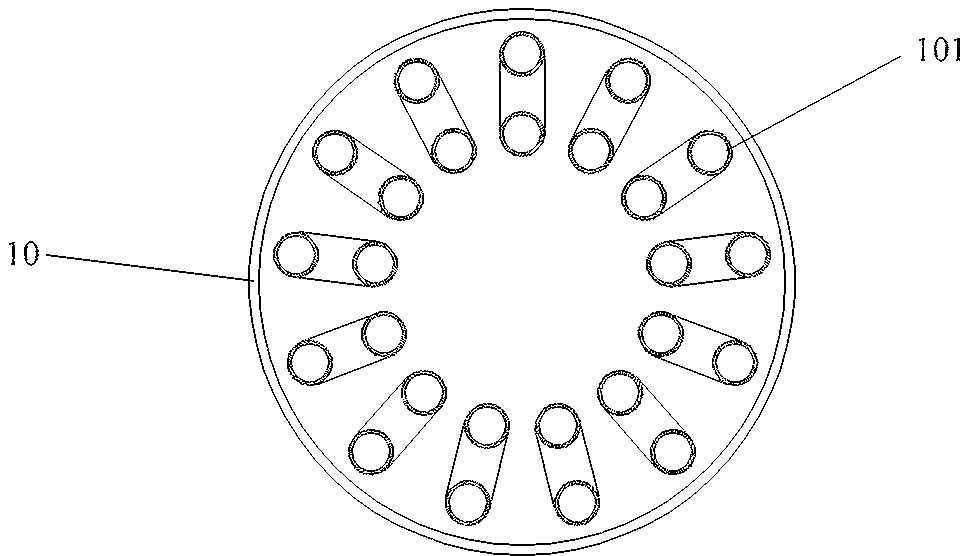

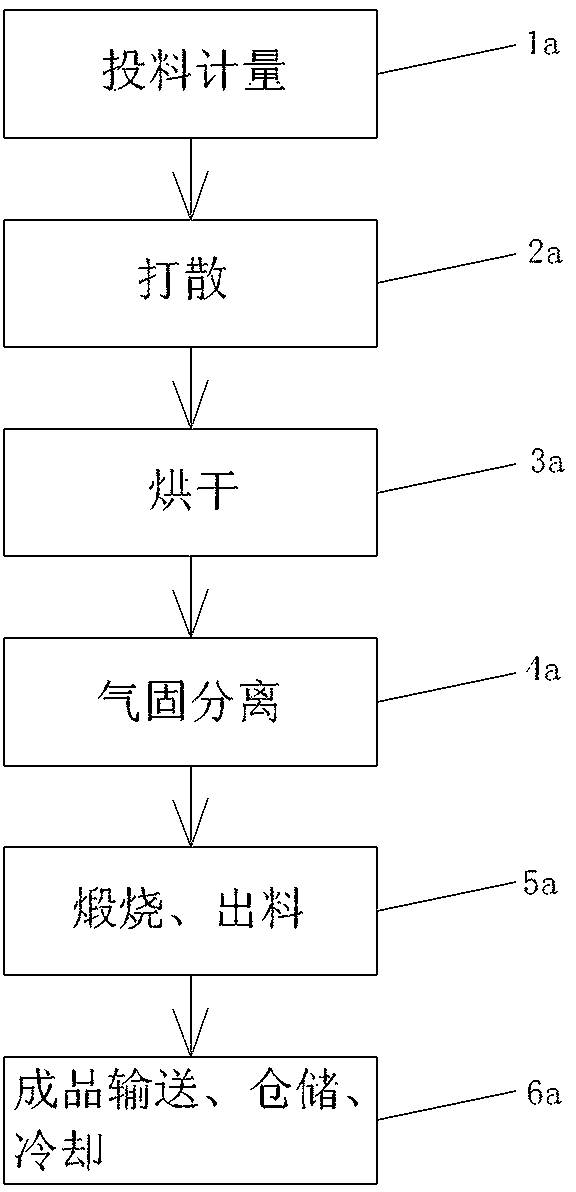

[0038] figure 1 , figure 2 As shown, a calcination production line for industrial by-product gypsum includes a feeding mechanism 1, a metering mechanism 2, an inclined conveyor belt 3, a breaking mechanism 4, a drying pipeline 5, a first gas-solid separation tower 6, a second Gas-solid separation tower 7, negative pressure fan 8, screw feeder 9, horizontal rotary calcination kiln 10, combustion furnace 11, finished product conveying mechanism 12, material storage tower 13, temperature detection and display system 14, PLC control for coordinating the actions of various mechanisms System 15 and water bath dust collector 16 and electrostatic precipitator 17;

[0039] The metering mechanism 2 is arranged between the feeding mechanism 1 and the inclined conveyor belt 3. The feeding mechanism 1 includes a storage hopper 11 and a horizont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com