Sm1-xCaxBiO3 buffering layer of high-temperature superconductivity coated conductor and preparation method thereof

A technology of coating conductors and high temperature superconductivity, which is applied in the field of high temperature superconducting material preparation, can solve the problems that the preparation cost affects the practical progress of high temperature coated conductors and the high melting point, and is suitable for large-scale deposition, simple production process and low cost. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

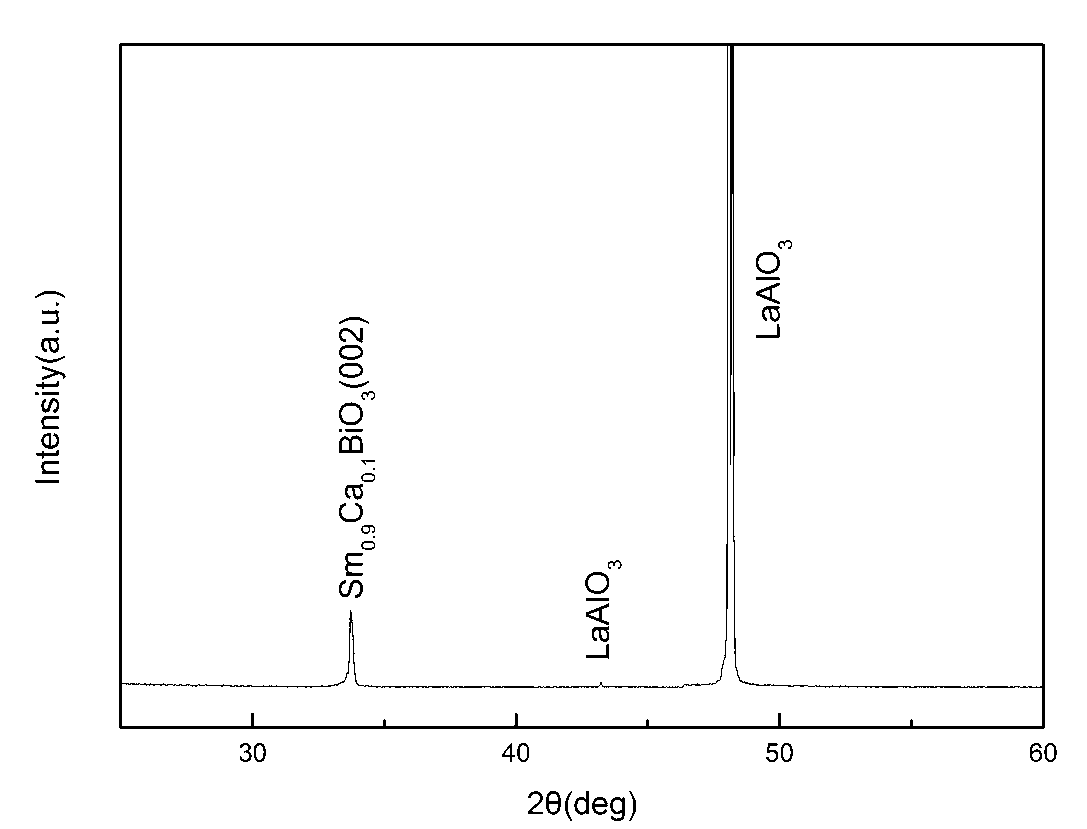

[0026] The invention provides a buffer layer Sm of a high-temperature superconducting coated conductor 0.9 Ca 0.1 BiO 3 . And a preparation of high temperature superconducting coating conductor Sm 0.9 Ca 0.1 BiO 3 The method for buffer layer thin film, its step is:

[0027] a.Sm 0.9 Ca 0.1 BiO 3 Preparation of the buffer layer colloid: the precursors Sm, Ca, and Bi nitrate were dissolved in an appropriate amount of polyacrylic acid (PAA) at a cation concentration of 0.9:0.1:1, thereby obtaining an organic system. The total molar concentration of the final solution is about 0.2mol / L.

[0028] b.Sm 0.9 Ca 0.1 BiO 3 Buffer layer coating, drying and decomposition: coating the colloid prepared in step a on LaAlO 3 On the single crystal substrate, dry at 100°C; then place it in a sintering furnace, slowly raise the furnace temperature from room temperature to 180°C in the air, and increase it to 280°C at a speed of 0.1°C / min, and then Raise to 570°C at a rate of 0.1°C / ...

Embodiment 2

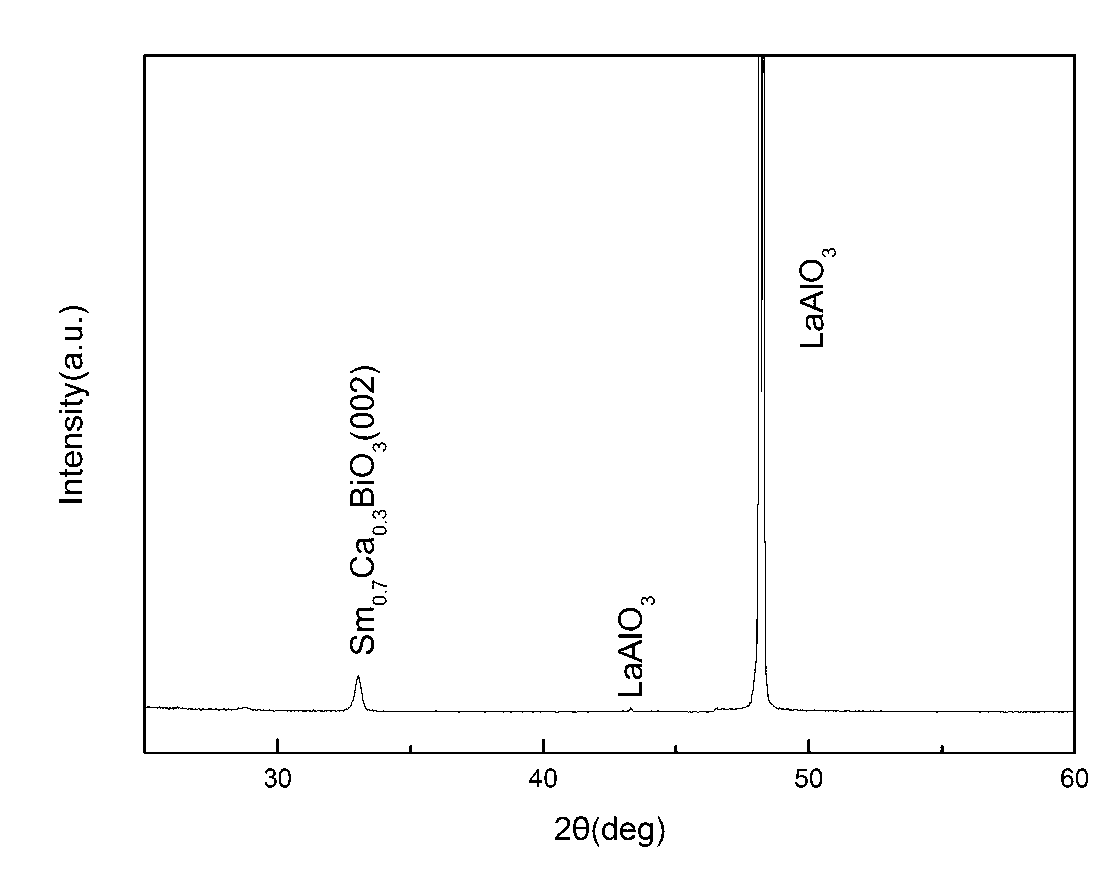

[0033] The invention provides a buffer layer Sm of a high-temperature superconducting coated conductor 0.7 Ca 0.3 BiO 3 . And a preparation of high temperature superconducting coating conductor Sm 0.7 Ca 0.3 BiO 3 The method for buffer layer thin film, its step is:

[0034] a.Sm 0.7 Ca 0.3 BiO 3 Preparation of the buffer layer colloid: the precursors Sm, Ca, and Bi nitrate are dissolved in an appropriate amount of polyacrylic acid (PAA) at a cation concentration of 0.7:0.3:1 to obtain an organic system. The total molar concentration of the final solution is about 0.2mol / L.

[0035] b.Sm 0.7 Ca 0.3 BiO 3 Buffer layer coating, drying and decomposition: coating the colloid prepared in step a on LaAlO 3 on a single crystal substrate, and then dried at 120°C; then placed in a sintering furnace, and the furnace temperature was slowly raised from room temperature to 200°C in the air, and then raised to 300°C at a speed of 2°C / min, and then Raise to 560°C at a rate of 0....

Embodiment 3

[0040] The invention provides a buffer layer Sm of a high-temperature superconducting coated conductor 0.6 Ca 0.4 BiO 3 . And a preparation of high temperature superconducting coating conductor Sm 0.6 Ca 0.4 BiO 3 The method for buffer layer thin film, its step is:

[0041] a.Sm 0.6 Ca 0.4 BiO 3 Preparation of the buffer layer colloid: the precursors Sm, Ca, and Bi nitrate were dissolved in an appropriate amount of polyacrylic acid (PAA) at a cation concentration of 0.6:0.4:1 to obtain an organic system. The total molar concentration of the final solution is about 0.2mol / L.

[0042] b.Sm 0.6 Ca 0.4 BiO 3 Buffer layer coating, drying and decomposition: coating the colloid prepared in step a on LaAlO 3 on a single crystal substrate, and then dried at 150°C; then placed in a sintering furnace, and the furnace temperature was slowly raised from room temperature to 230°C in the air, and then raised to 290°C at a speed of 1°C / min, and then Raise to 580°C at a rate of 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com