Environment-friendly chlorohydrin formula

A chlorohydrin and formulation technology, applied in the field of environmentally friendly chlorohydrin formulations, can solve the problems of poor ozone resistance, low air permeability and coagulation force, reduced rubber strength and other mechanical properties, etc., and achieves improved ozone resistance and fuel penetration resistance. The effect of high temperature resistance and quality improvement

Active Publication Date: 2012-10-03

TIANJIN BINHAI NEW DISTRICT DAGANG TIANLI RUBBER HOSE

View PDF1 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This material has excellent oil resistance, aging resistance and wear resistance, low air permeability and high cohesion, but poor ozone resistance

Although nitrile rubber can be used continuously at 120°C, and has excellent oil resistance and low price, the fuel hose has to be in contact with various oils for a long time during use, and the oil can penetrate into the rubber to cause swelling, resulting in Molecules diffuse each other, and then change the network structure of vulcanized rubber, resulting in a reduction in the strength and other mechanical properties of the rubber

At the same time, with the development of the automobile industry and the enhancement of environmental protection awareness, the performance of the original fuel hose can no longer meet the ever-changing performance requirements of automobiles, and the requirements for oil permeability are very high, and the requirements for ozone resistance have also increased from the original 50pphm to 200pphm. Therefore, there must be a new product to meet the performance requirements of the car. Usually, nitrile rubber and neoprene are extruded at the same time without adding adhesive materials. The two glues can be well bonded together. Fluorine glue and chlorohydrin glue have higher performance, and the ordinary formula of the two materials replaced is difficult to bond together, so it is necessary to use a special adhesive to bond the two materials together.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

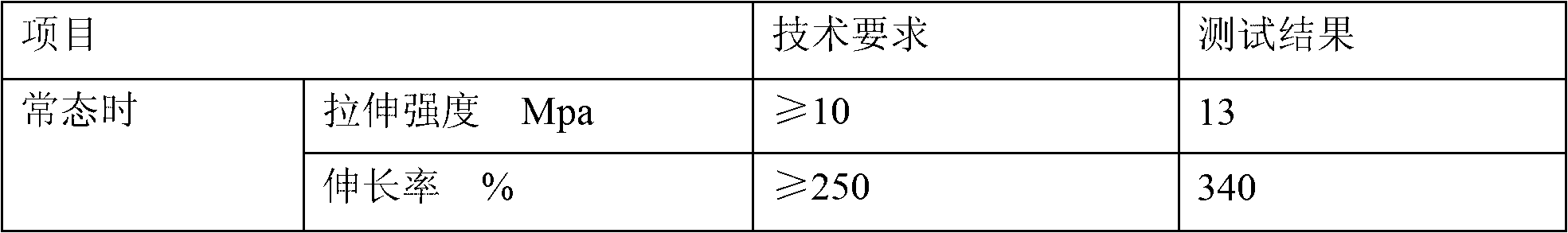

example 1

[0014] serial number

example 2

[0016] serial number

[0017] 2

example 3

[0019] serial number

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

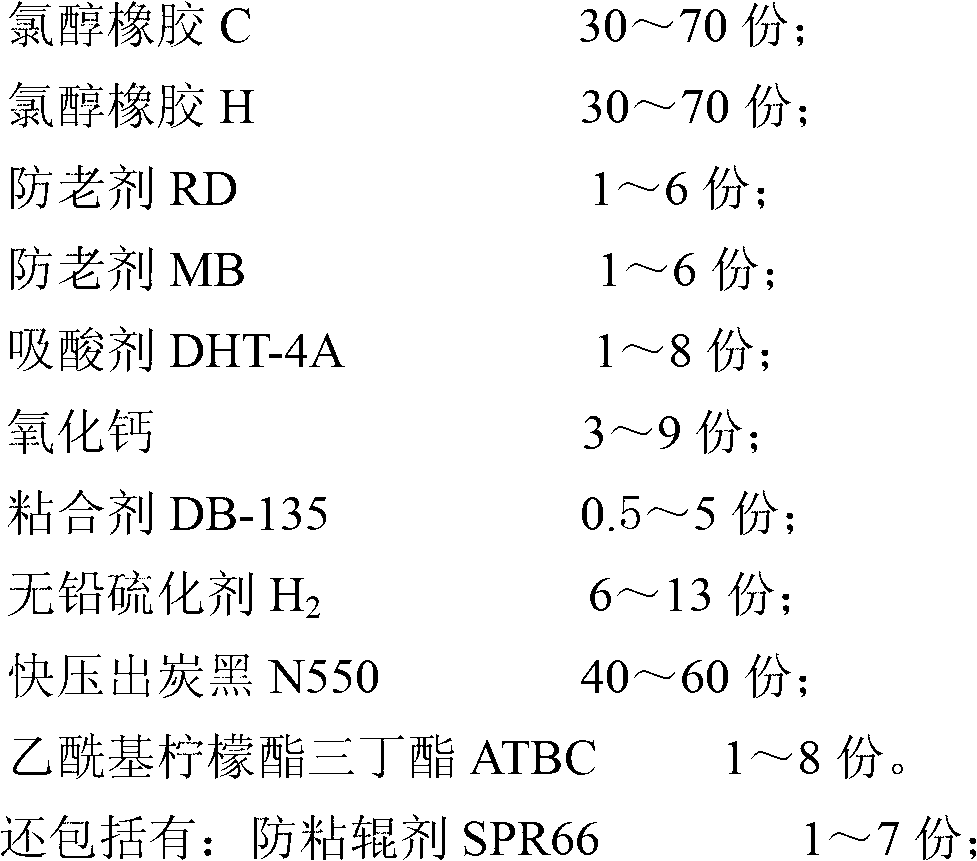

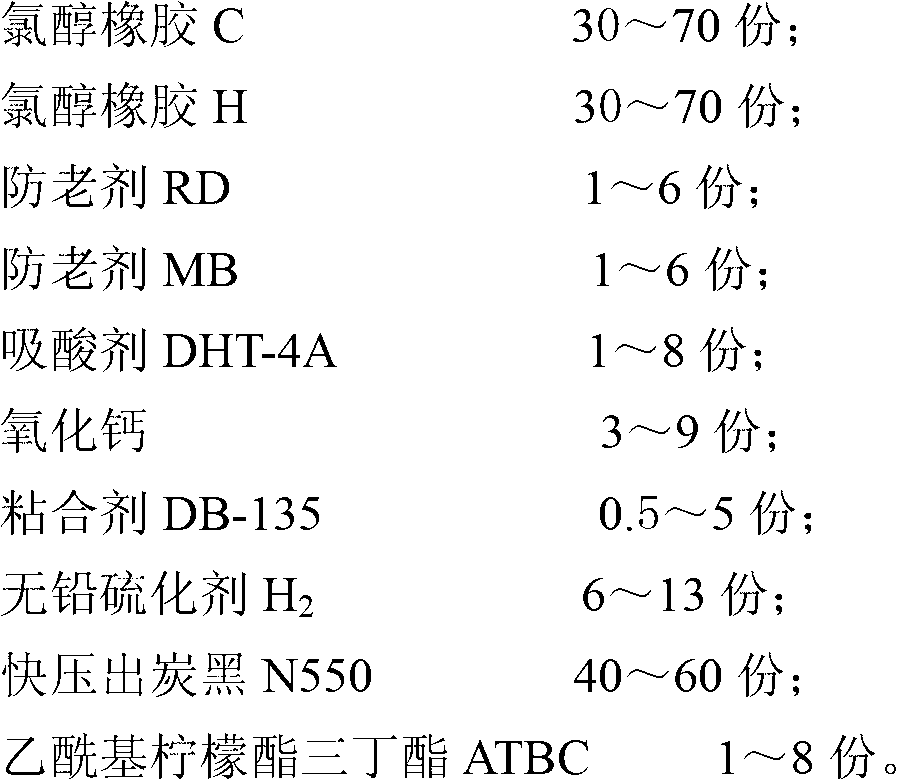

The invention relates to an environment-friendly chlorohydrin formula, which comprises the following ingredients in part by weight: 30 to 70 parts of epichlorohydrin rubber C, 30 to 70 parts of epichlorohydrin rubber H, 1 to 6 parts of anti-aging agent RD, 1 to 6 parts of anti-aging agent MB, 1 to 8 parts of acid-acceptor DHT, 3 to 9 parts of calcium chloride, 0.5 to 5 parts of bonding agent DB-135, 6 to 13 parts of lead-free vulcanizing agent, 40 to 60 parts of fast extruded carbon black N550 and 1 to 8 parts of acetyl tributyl citratecas ATBC. The environment-friendly chlorohydrin formula also comprises 1 to 7 parts of anti-sticking agent SPR66. Due to the adoption of the environment-friendly chlorohydrin formula, the bonding problem for simultaneously extruding a chloride rubber compound and a chlorohydrin rubber compound can be solved, the high temperature resistance, the hot oil resistance, the ozone resistance and the fuel penetration resistance of the environment-friendly chlorohydrin can be improved, not only is environmental protection realized, but also the two materials can be well and adequately bonded together, the product quality can be improved, and the customer demand can be met.

Description

technical field [0001] The invention relates to an environment-friendly chlorohydrin. In particular, it relates to an environmentally friendly chlorohydrin formulation. Background technique [0002] The fuel hose system for automobiles in my country generally uses nitrile rubber / skeleton layer / neoprene rubber. This material has excellent oil resistance, aging resistance and wear resistance, low air permeability and high cohesion, but poor ozone resistance. Although nitrile rubber can be used continuously at 120°C, and has excellent oil resistance and low price, the fuel hose has to be in contact with various oils for a long time during use, and the oil can penetrate into the rubber to cause swelling, resulting in Molecules diffuse with each other, thereby changing the network structure of vulcanized rubber, resulting in a decrease in the strength and other mechanical properties of the rubber. At the same time, with the development of the automobile industry and the enhanc...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L71/00C08L27/12C08K13/02C08K3/02C08K3/22

Inventor 贾炳顺贾恩馨李继兰赵金明贾斌

Owner TIANJIN BINHAI NEW DISTRICT DAGANG TIANLI RUBBER HOSE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com