High-glow-wire-temperature red phosphorus flame-retardant reinforced PA (polyamide) 66 and PPE (polyphenyl ether) alloy material and preparation method thereof

A high-glow wire and alloy material technology, which is applied in the field of high-glow wire red phosphorus flame retardant PA66 and PPE alloy materials and their preparation, can solve the problems of inability to achieve halogen-free and special properties, and export enterprises' troubles, so as to improve the comprehensive Competitiveness, easy to master technology, good rigid effect

Active Publication Date: 2012-10-03

5ELEM HI TECH CORP

View PDF2 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Among them, the environmental protection and halogen-free requirements for the materials of electronic and electrical products must also meet the above-mentioned properties, so many export companies in my country have caused serious troubles, and they cannot meet the requirements of halogen-free and special properties at the same time.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

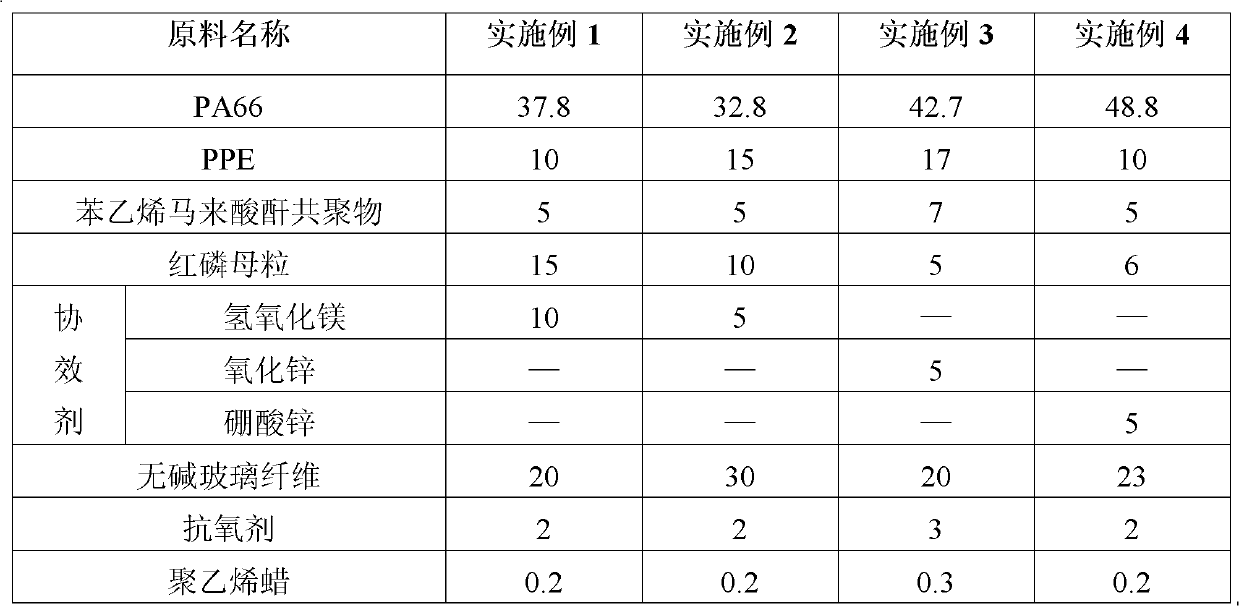

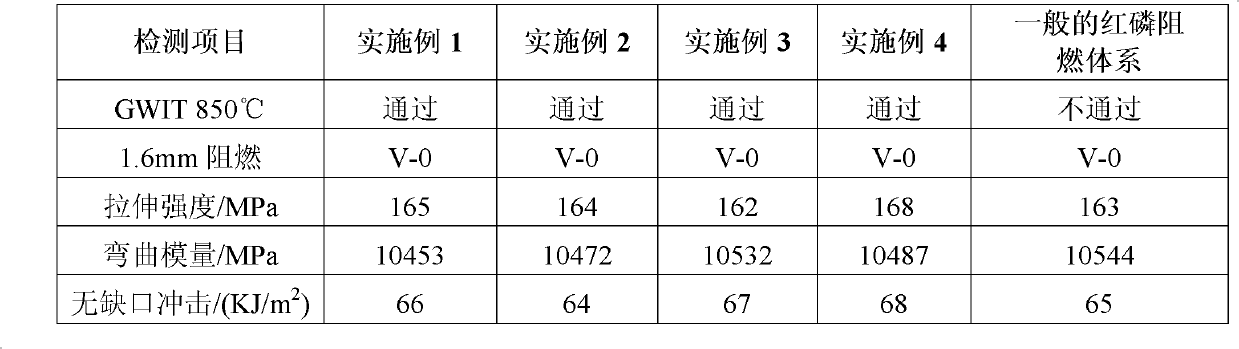

Embodiment 1~4

[0037] Proportioning ratio 1-4 (weight %) of each component in table 1 embodiment 1~4

[0038]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a high-glow-wire-temperature red phosphorus flame-retardant reinforced PA (polyamide) 66 and PPE (polyphenyl ether) alloy material and a preparation method thereof. The high-glow-wire-temperature red phosphorus flame-retardant reinforced PA66 and PPE alloy material includes the following components in each 100 parts of raw materials and content of the components, by weight, 30-50% of PA66, 10-20% of PPE, 5-20% of red phosphorus masterbatch, 20-35% of glass fibers, 5-15% of synergistic agent, 5-10% of compatilizer, 2-5% of antioxidant and 0.1-0.5% of auxiliaries. The high-glow-wire-temperature red phosphorus flame-retardant reinforced PA66 and PPE alloy material can be formed in an extrusion or injection manner by corresponding equipment such as an extruder. Compared with the conventional material, the high-glow-wire-temperature red phosphorus flame-retardant reinforced PA66 and PPE alloy material can pass the test of the GWIT (glow wire ignition temperature) of 850 DEG C, cannot be ignited, is controllable in processing and stable in flame retardant, quite fine in rigidity, high in fire resistance, stable in size and capable of meeting requirements of various electronic and electric products.

Description

technical field [0001] The invention relates to a high glow wire red phosphorus flame retardant PA66 and PPE alloy material and its preparation method, in particular to an engineering material product suitable for injection molding with high electrical performance and flame retardant enhancement requirements, suitable for low-voltage electrical appliances, circuit breakers Polyamide modified materials such as device, motor carbon brush bracket, etc., belong to the technical field of polymer modification. Background technique [0002] Nylon 66 is a homogeneous thermoplastic polymer with six symmetrical methylene groups in its molecular structure. It has the advantages of high strength, wear resistance, solvent resistance, good self-lubrication and wide temperature range. It is the most widely used One of engineering plastics, widely used in various electronic and electrical equipment and home appliances. Nearly 80% of the flame retardants used in the current flame-retardant ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L77/06C08L71/12C08L35/06C08K13/06C08K9/06C08K7/14C08K9/10C08K3/02C08K3/38C08K3/22B29B9/06

Inventor 沙月华冯玉婷黄骥

Owner 5ELEM HI TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com