Electric-heating far-infrared health-protection material, preparation method and application thereof

A technology of far-infrared health care and health care materials, applied in the field of functional electrothermal materials, can solve problems such as unsatisfactory effects, stay at the stage of theory and exploration, and single function, so as to improve the environmental microclimate, help metabolic activities, and reduce electromagnetic radiation. radiation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

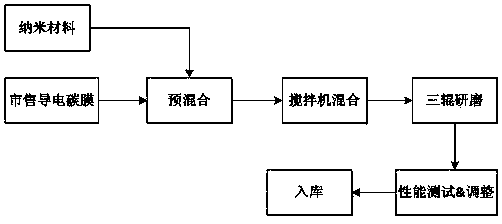

[0043] Example 1: fumed white carbon black, particle size 7-80nm; nano-active calcium silicate, particle size 20-50nm; nano-precipitated barium sulfate, particle size 20-100nm; nano-tourmaline powder, particle size 20-50nm. The addition amounts are 0.3%, 0.7%, 1.5%, and 3.0% of the weight of the conductive carbon ink, respectively. Add the above weighed nanomaterials to the 5L plastic tank equipped with the EA-ST208B ink mixer (1000g of commercially available conductive carbon ink weighed in the container has been placed in advance). Stir by hand to make it preliminarily mix, then place the plastic tank on the fixed seat of the ink mixer, stir at a speed of 100rpm for 30 minutes, and mix thoroughly, and then grind the mixed carbon ink twice through a three-roller grinder Then put it in a special container and place it at 22°C for 48 hours before use.

Embodiment 2

[0044] Example 2: fumed white carbon black, particle size 7-80nm; nano-active calcium silicate, particle size 20-50nm; nano-precipitated barium sulfate, particle size 20-100nm; nano-tourmaline powder, particle size 20-50nm. The addition amount is respectively 0.4%, 1.0%, 0.8%, 1.5% of the weight of the conductive carbon ink. Add the above weighed nanomaterials to the 5L plastic tank equipped with the EA-ST208B ink mixer (1500g of commercially available conductive carbon ink weighed in the container has been placed in advance). Stir by hand to make it preliminarily mix, then place the plastic tank on the fixed seat of the ink mixer, stir at a speed of 100rpm for 30 minutes, and mix thoroughly, and then grind the mixed carbon ink twice through a three-roller grinder Then put it in a special container and place it at 20°C for 36 hours before use.

Embodiment 3

[0045] Example 3: precipitated white carbon black, particle size 7-80nm; nano-active calcium silicate, particle size 20-50nm; nano-precipitated barium sulfate, particle size 20-100nm; nano-tourmaline powder, particle size 20-50nm. The addition amounts are 0.5%, 0.4%, 1.2%, and 2.5% of the weight of the conductive carbon ink, respectively. Add the above weighed nanomaterials to the 5L plastic tank equipped with the EA-ST208B ink mixer (2000g of commercially available conductive carbon ink weighed in the container has been placed in advance). Stir by hand to make it preliminarily mix, then place the plastic tank on the fixed seat of the ink mixer, stir at a speed of 100rpm for 30 minutes, and mix thoroughly, and then grind the mixed carbon ink twice through a three-roller grinder Then put it in a special container at 25°C for 28 hours before use.

[0046] The manufacturability indexes of the heat-generating coatings prepared in the above-mentioned Examples 1-3 all need to meet ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com