Antirust paint

An anti-rust coating and anti-rust treatment technology, which is applied in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., and can solve the problems of reduced storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] a) Preparation of test objects

[0041] Using a coater, the rust inhibitor of the present invention (solid content: 20% by weight) was applied to commercially available electrogalvanized steel "EG-MO" and fusion sprayed coating at a dry film thickness of 1 µm. Al-10% Si steel (plating amount is 30g / m 2 ), and then dried at PMT 150°C.

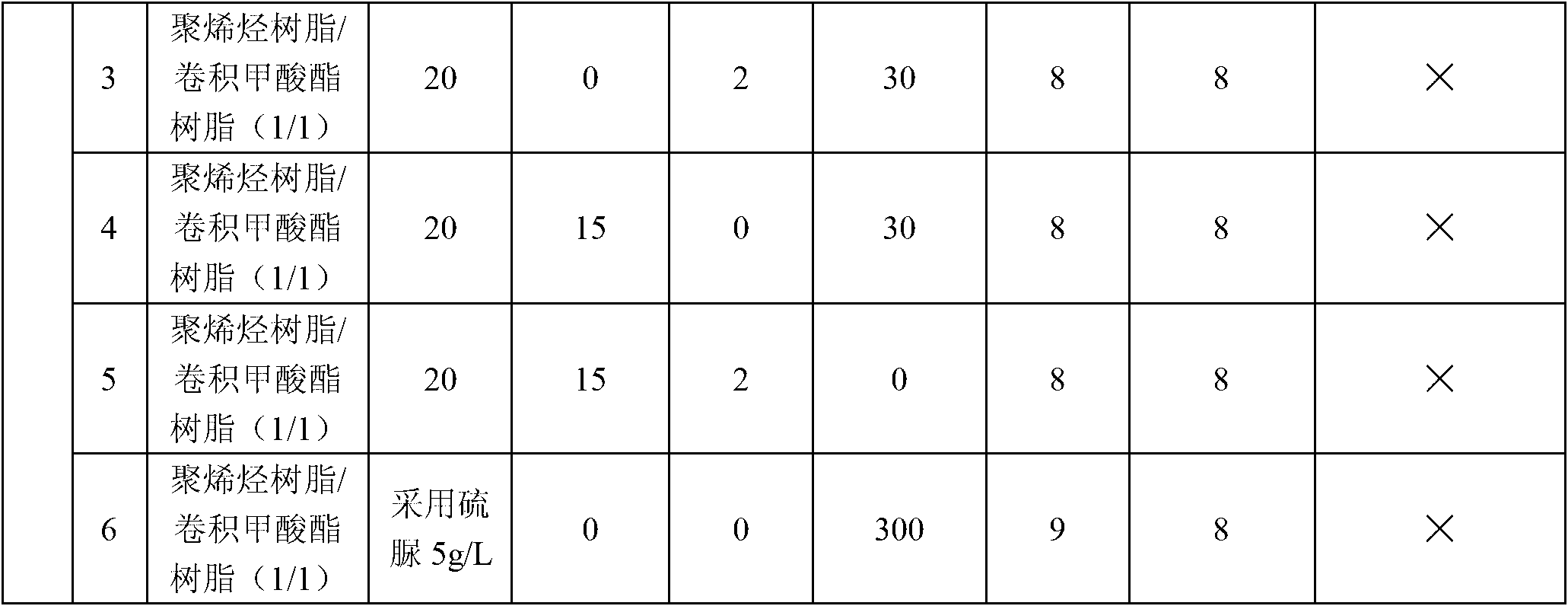

[0042] b) Salt spray test (SST resistance)

[0043] At 35°C, a 5% aqueous solution of sodium chloride was sprayed onto the coated side of the coated article, and after 360 hours, the matte area and the Ericssen (Ericssen) 7mm extruded area were evaluated, graded to achieve 10 is the best. The evaluation criteria are as follows.

[0044] 10 points: no abnormality

[0045] 9 points: between 10 points and 8 points

[0046] 8 points: Slight white rust formation

[0047] 7-6 points: between 8 points and 5 points

[0048] 5 points: White rust is formed on half the area

[0049] 4-2 points: between 5 points and 1 point

[0050] 1 point...

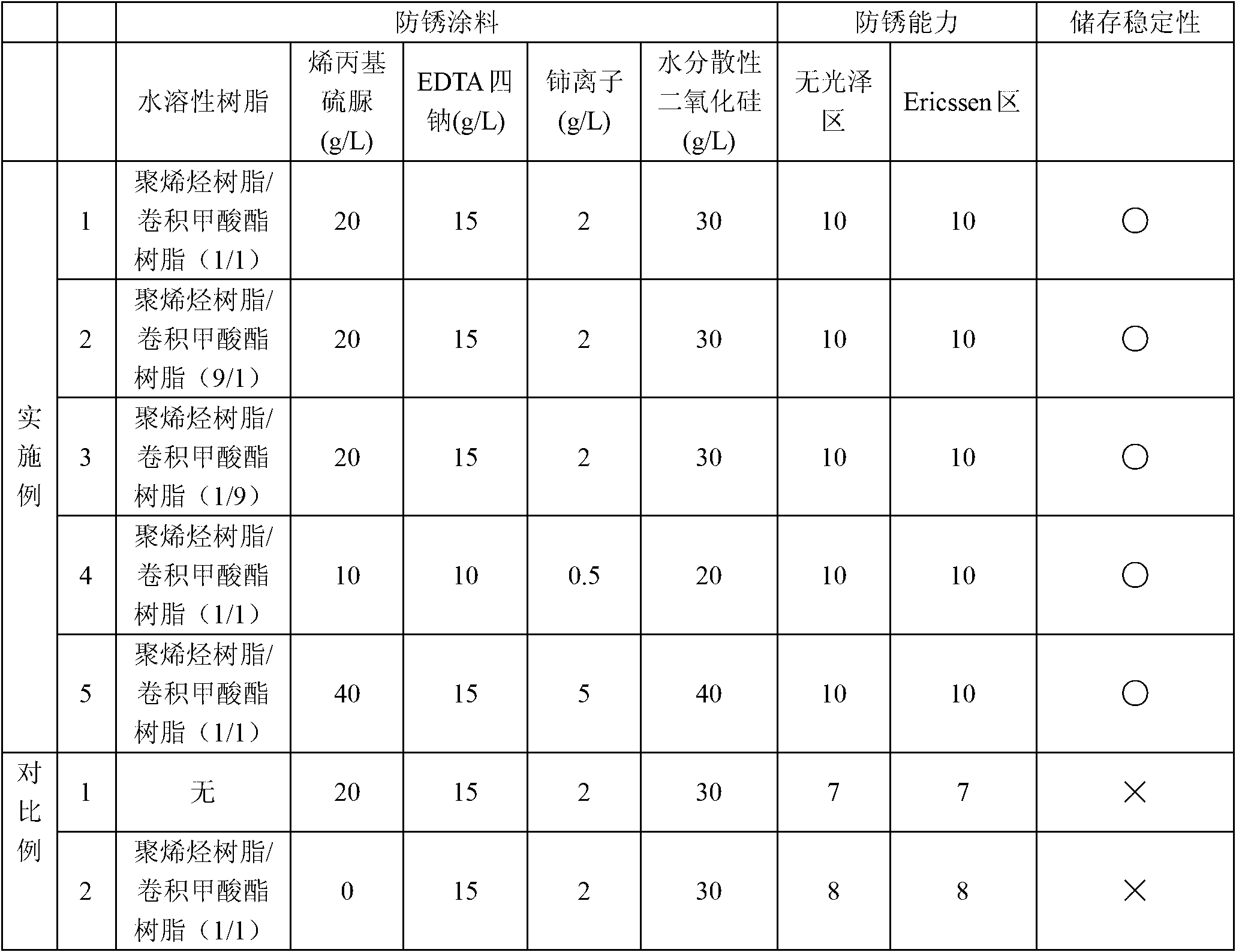

Embodiment 1

[0058] A polyolefin resin and a polyurethane resin were mixed in pure water at a solid ratio of 1:1 to obtain a total resin solid concentration of 20% by weight. Then dissolve 20g / L allylthiourea, 15g / L LEDTA tetrasodium, 2g cerium ion, and finally add water-dispersible silica at 30g / L. Stir for 30 minutes to disperse the mixture, then adjust the pH to 8.0 to obtain an antirust paint. To evaluate the antirust ability of the substrates and the adhesion of the topcoat, the obtained antirust coatings were applied to commercial electrogalvanized steel and dried as described in the evaluation section above. Electroplated galvanized steel was degreased with an alkaline degreaser, washed with water, and dried prior to evaluation. The evaluation results are shown in Table 1.

Embodiment 2-5

[0060] Antirust paint was prepared similarly to Example 1, except that the content of each substance used was different from Example 1. The specific composition is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com