Method for recovering valuable metal from red soil nickel minerals comprehensively

A technology of valuable metals and laterite nickel ore, applied in the direction of improving process efficiency, etc., can solve the problems of low recovery rate of nickel and cobalt, small consumption, high investment cost, etc., reduce acid consumption in leaching reaction, and solve production costs High cost, the effect of increasing economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

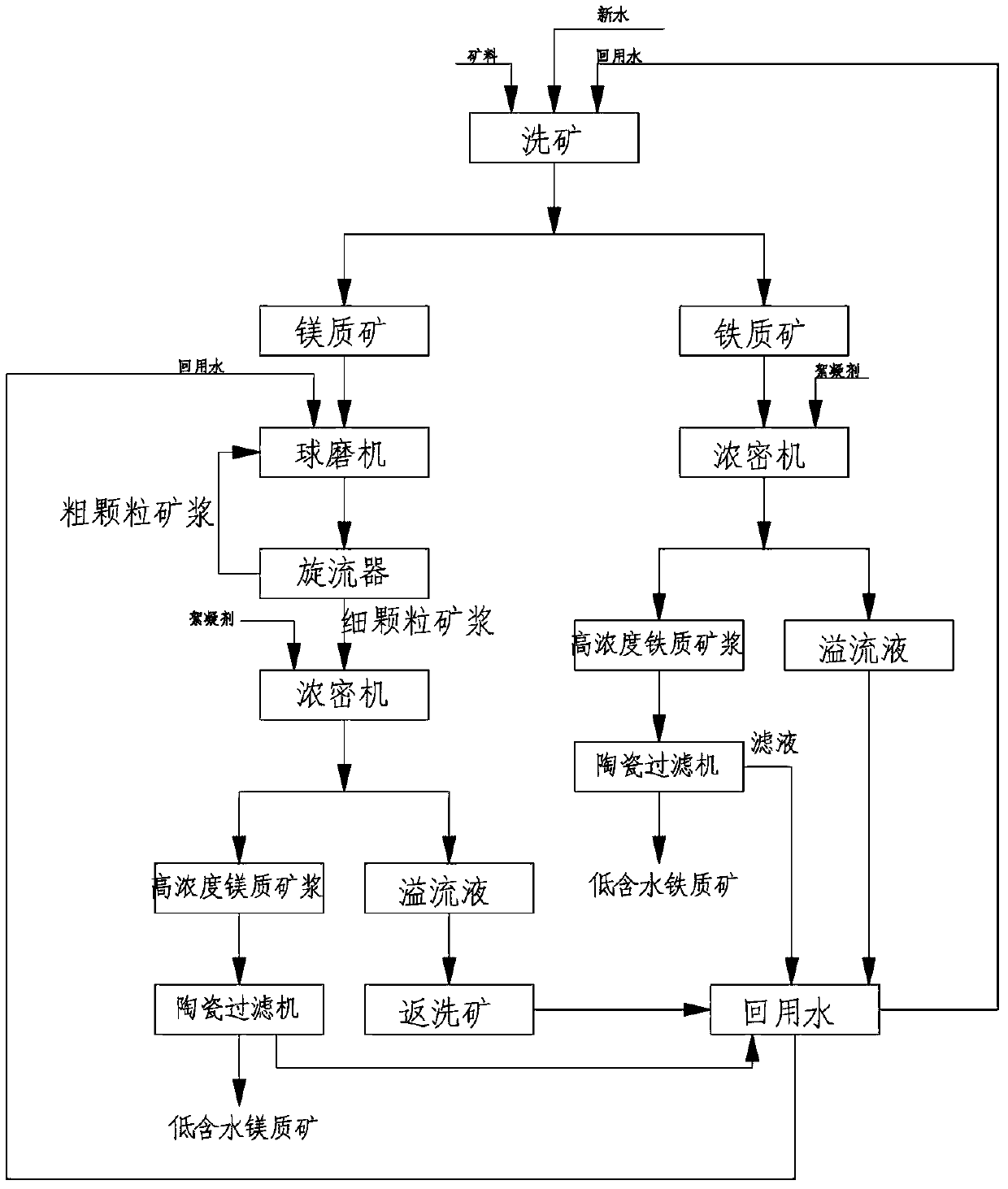

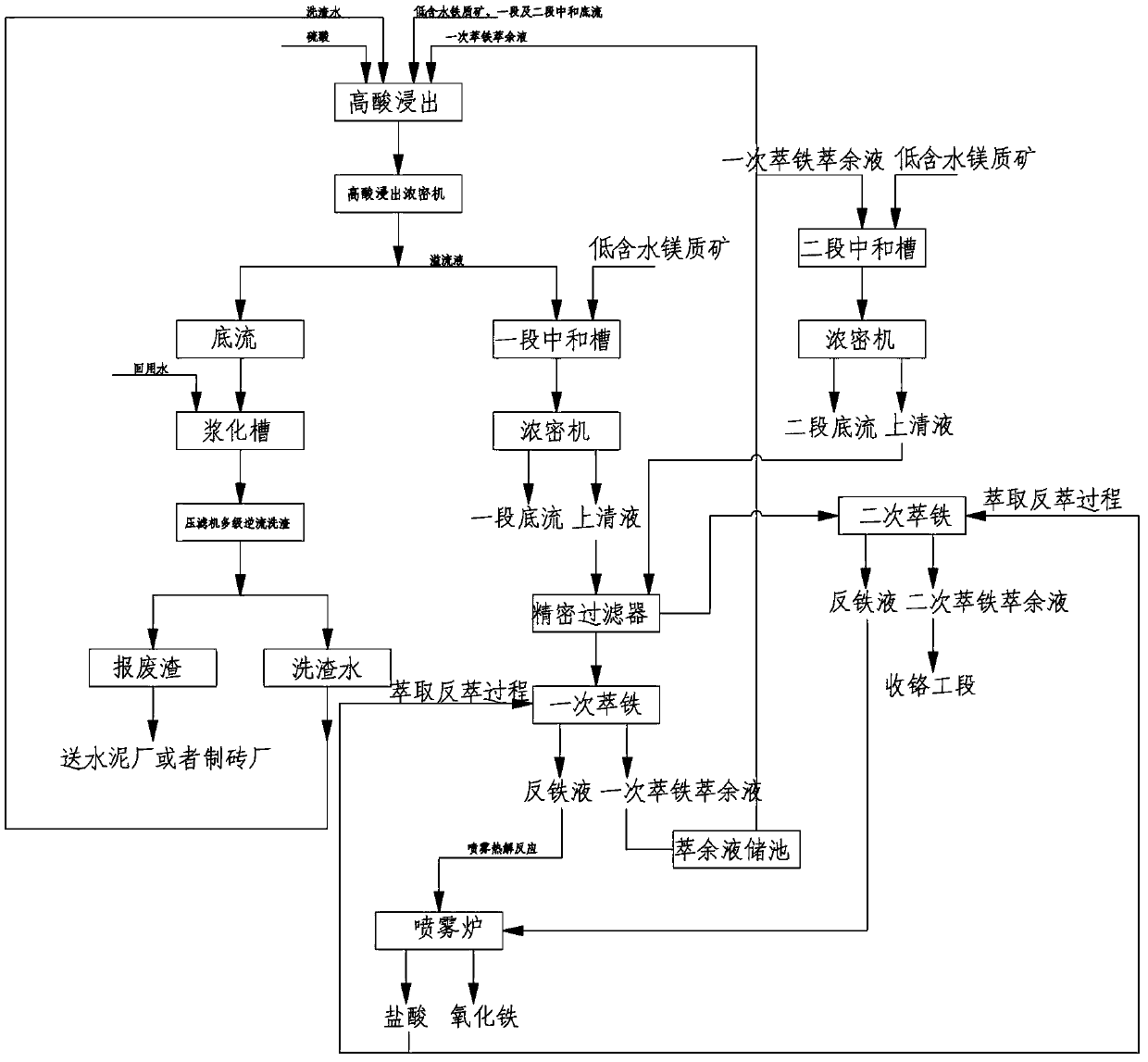

[0034] Mineral material preparation section flow process of the present invention is as figure 1 Shown: Add recycled water to the mineral material for washing operation (when there is no recycled water at the beginning, use new water), due to the difference in particle size, the mineral material is screened into iron ore and magnesia; iron ore It is finer and directly enters the thickener for solid-liquid sedimentation separation. During the separation process, flocculants need to be added to concentrate the pulp concentration to 30-55%. The concentrated underflow of the thickener enters the ceramic filter (or belt filter) for further processing. Dehydration, reduce the water content of the ore material to 15-20%, and the obtained low-water iron ore is transported to the high-acid leaching tank in the next section through the belt, and the thickener overflow liquid and the ceramic filter filtrate flow into the reuse water pool; magnesium The ore is coarser than iron ore, and i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| turbidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com