Method and device for controlling seed crystal melting degree through gas flow in single crystal casting process

An air flow control and seed crystal technology, applied in chemical instruments and methods, single crystal growth, crystal growth and other directions, can solve the problems of bottom seed crystal melting, high heater power, and difficulty in precise changes, and achieve the seed crystal melting speed. The effect of slowing down, reducing heat fluctuations, and effective melting degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

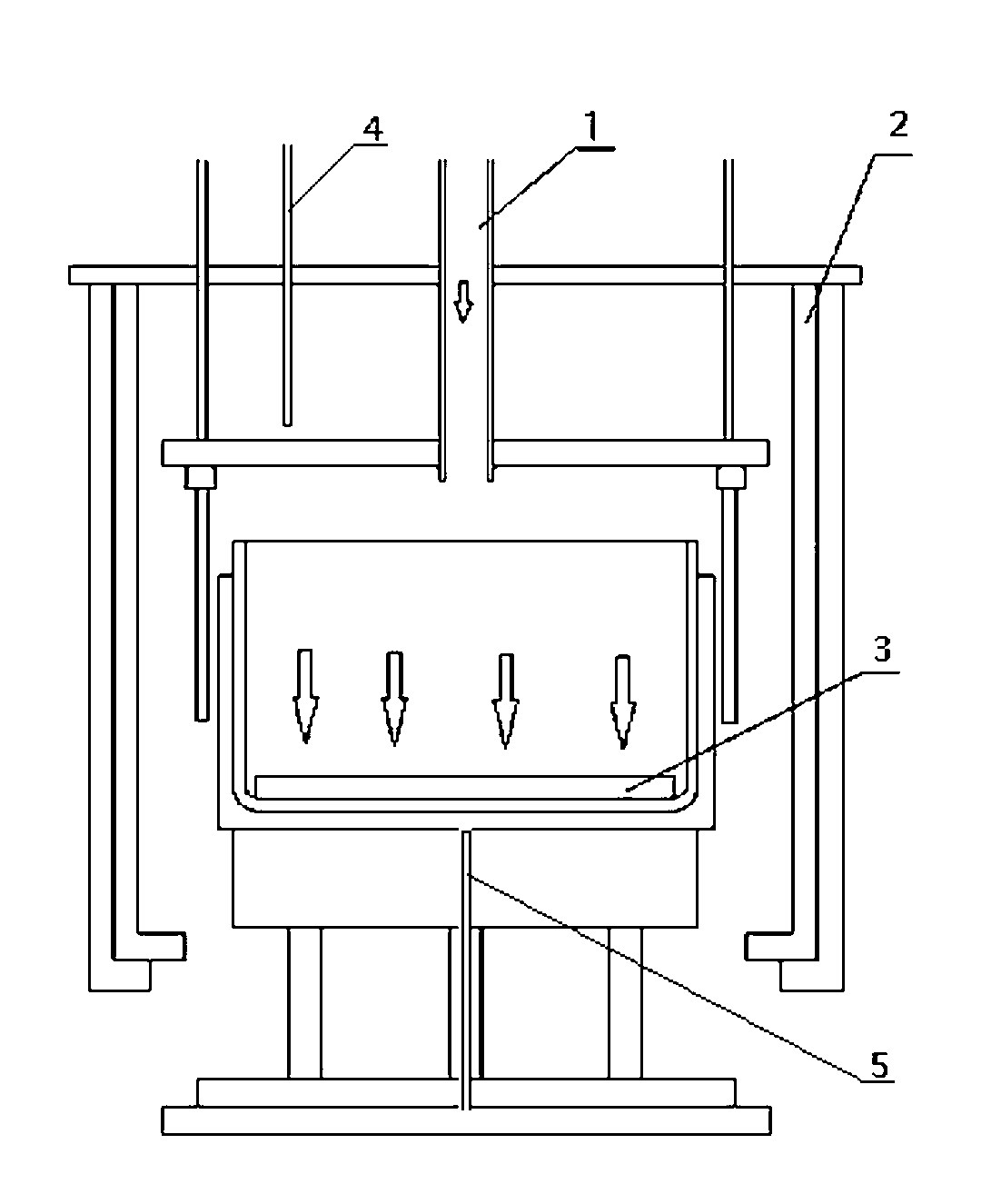

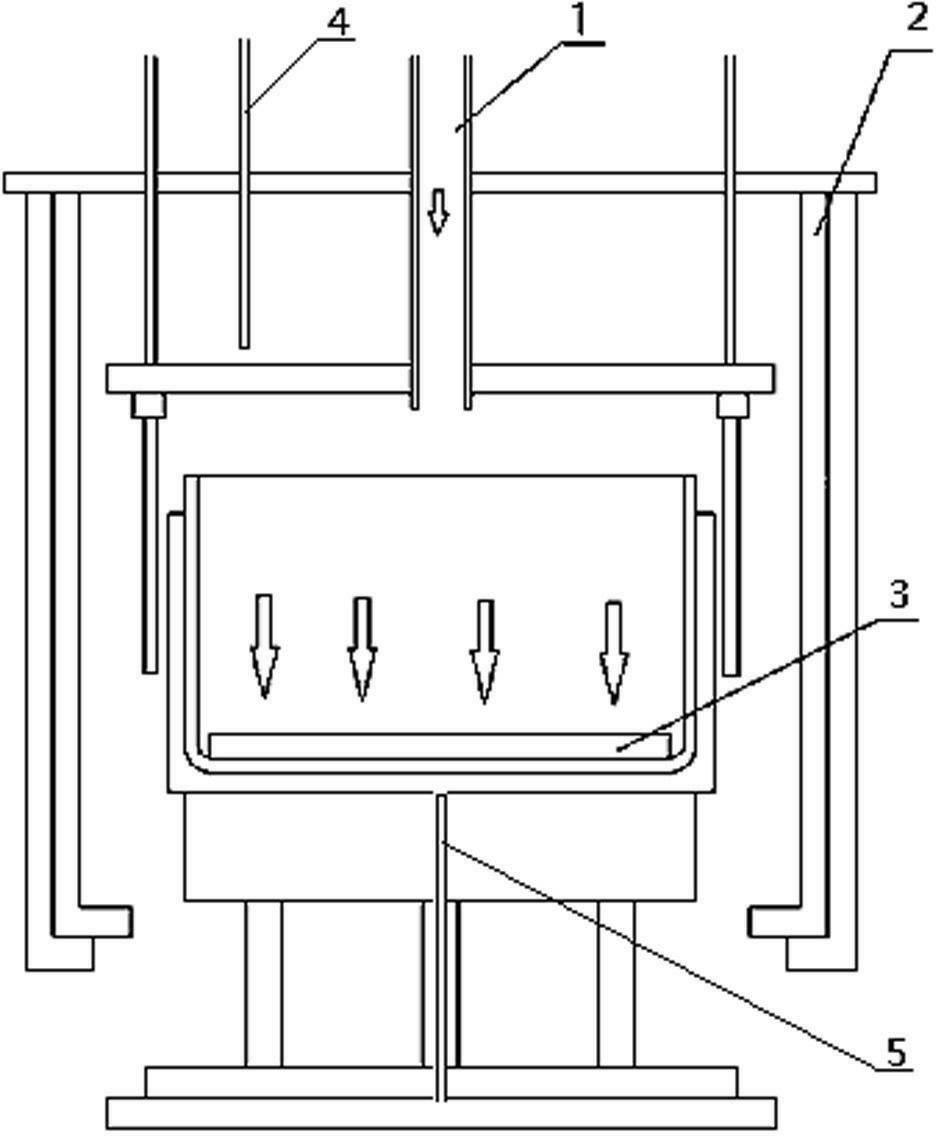

[0026] In order to make the present invention easier to understand, the purpose, features and advantages are more prominent, below in conjunction with examples and accompanying figure 1 for further clarification.

[0027] A device that controls the degree of melting of the seed crystal through the airflow during the process of casting a single crystal, such as figure 1 As shown, it includes a polycrystalline ingot casting furnace, and the polycrystalline ingot casting furnace is provided with a heat insulation cage 2, and the top of the heat insulation cage is provided with a graphite air duct 1 leading to a protective gas in the furnace, and the heat insulation cage 2 is equipped with a temperature control thermocouple 4, and the bottom of the polycrystalline ingot casting furnace is provided with a thermocouple 5 at the bottom of the directional solidification block

[0028] A seed crystal layer 3 is laid on the bottom of the crucible in the furnace body, and polysilicon ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com