Boiler and air preheating system thereof

A technology of air preheating and air preheater, applied in the field of electric power, can solve the problems of high exhaust gas temperature, shortening the service life of air preheater, and increasing maintenance cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The core of the present invention is to provide an air preheating system for a boiler, which can significantly reduce the exhaust gas temperature and improve the thermal efficiency of the boiler. Another core of the present invention is to provide a boiler comprising the above-mentioned air preheating system.

[0021] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

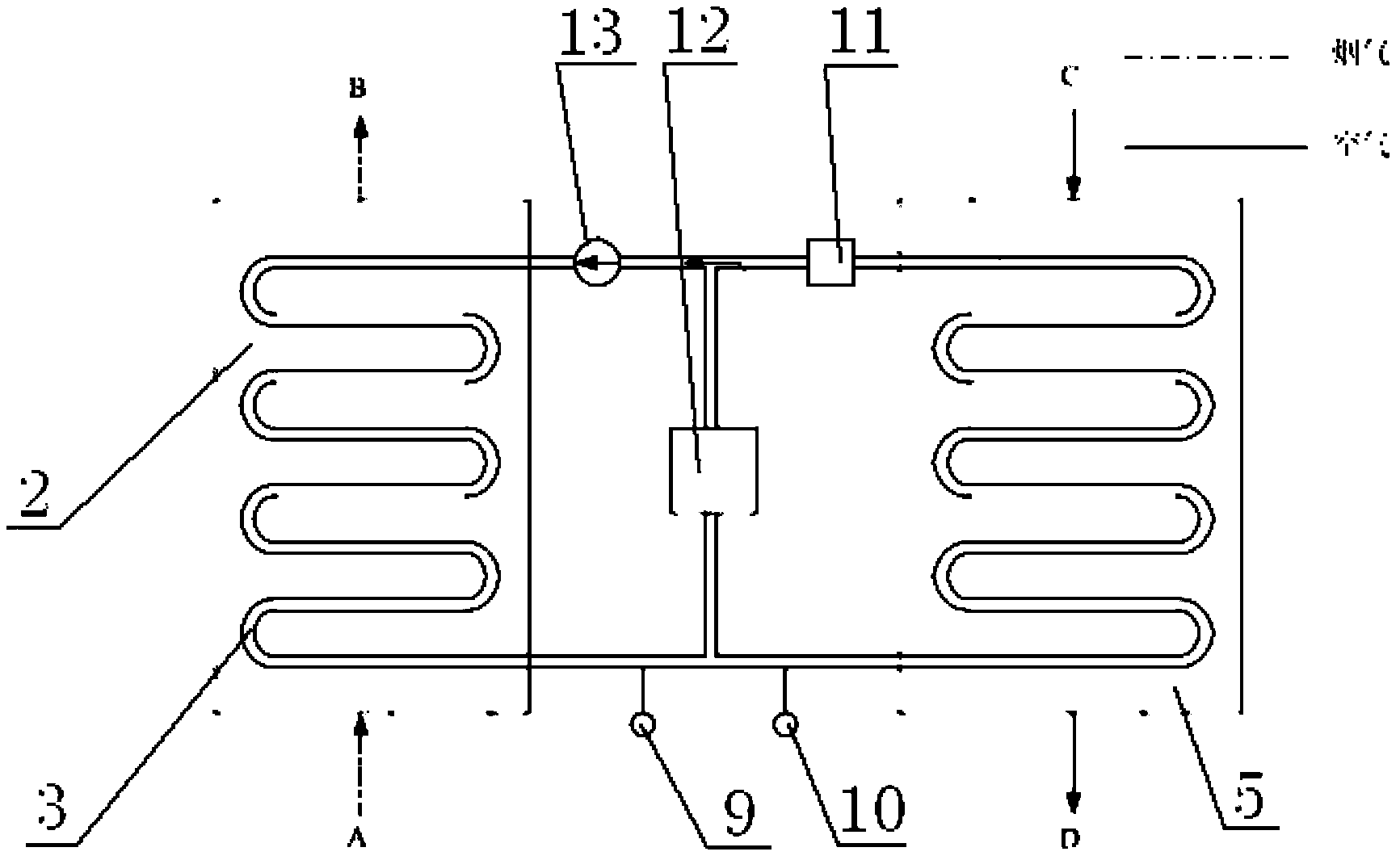

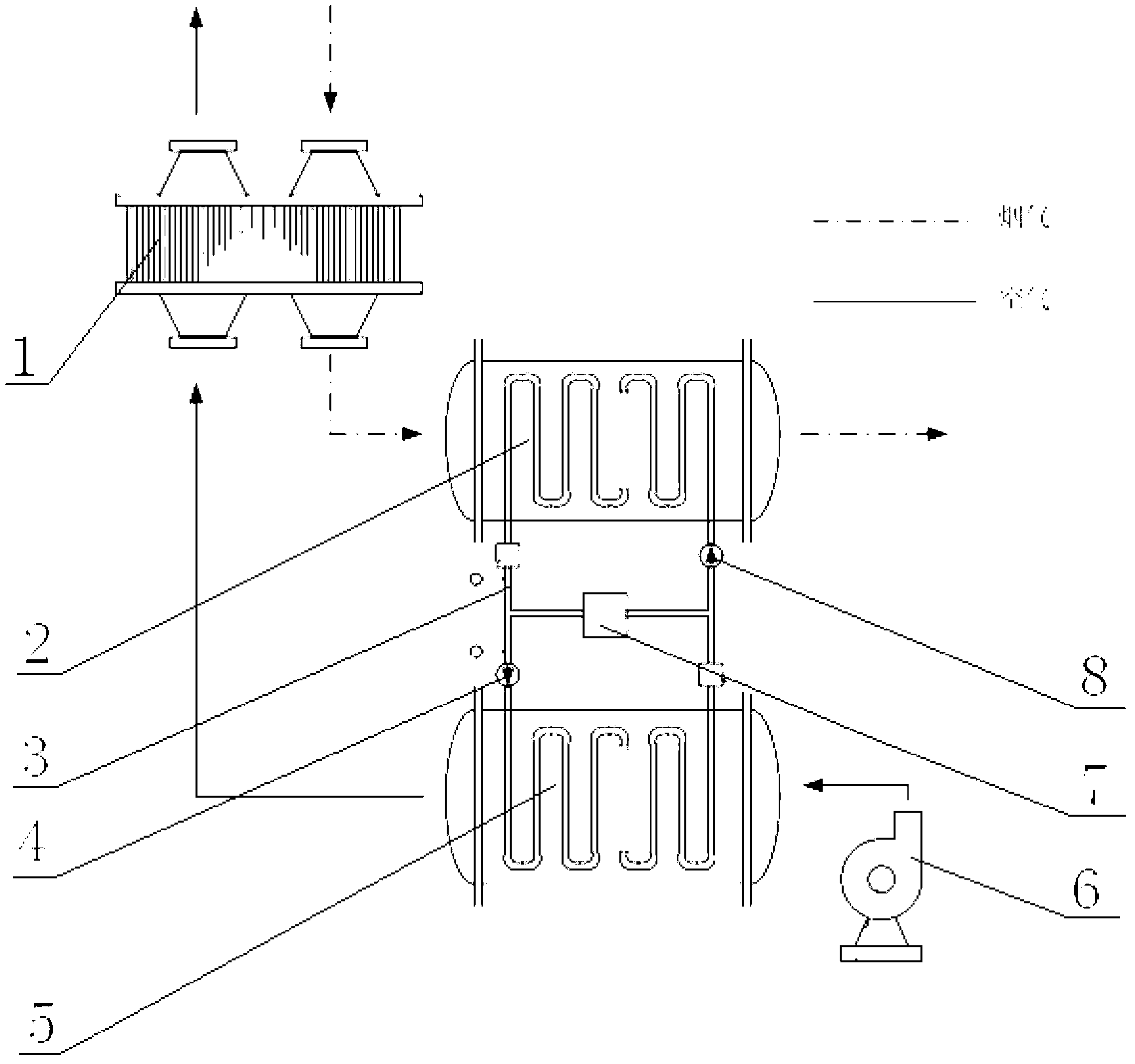

[0022] Please refer to figure 1 and figure 2 , figure 1 It is a working schematic diagram in a specific embodiment of the air preheating system provided by the present invention, figure 2 for figure 1 The schematic diagram of the closed loop circuit between the flue gas heat exchanger and the air heat exchanger in the air preheating system shown.

[0023] In a specific embodiment, the air preheating system provi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap