Photoresist recovery system

A recycling system and photoresist technology, applied in photosensitive material processing, electrical components, semiconductor/solid-state device manufacturing, etc., can solve problems such as inability to recycle photoresist, waste of photoresist, and pollution of photoresist, To facilitate viscosity adjustment and reuse, improve recycling rate, and protect purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

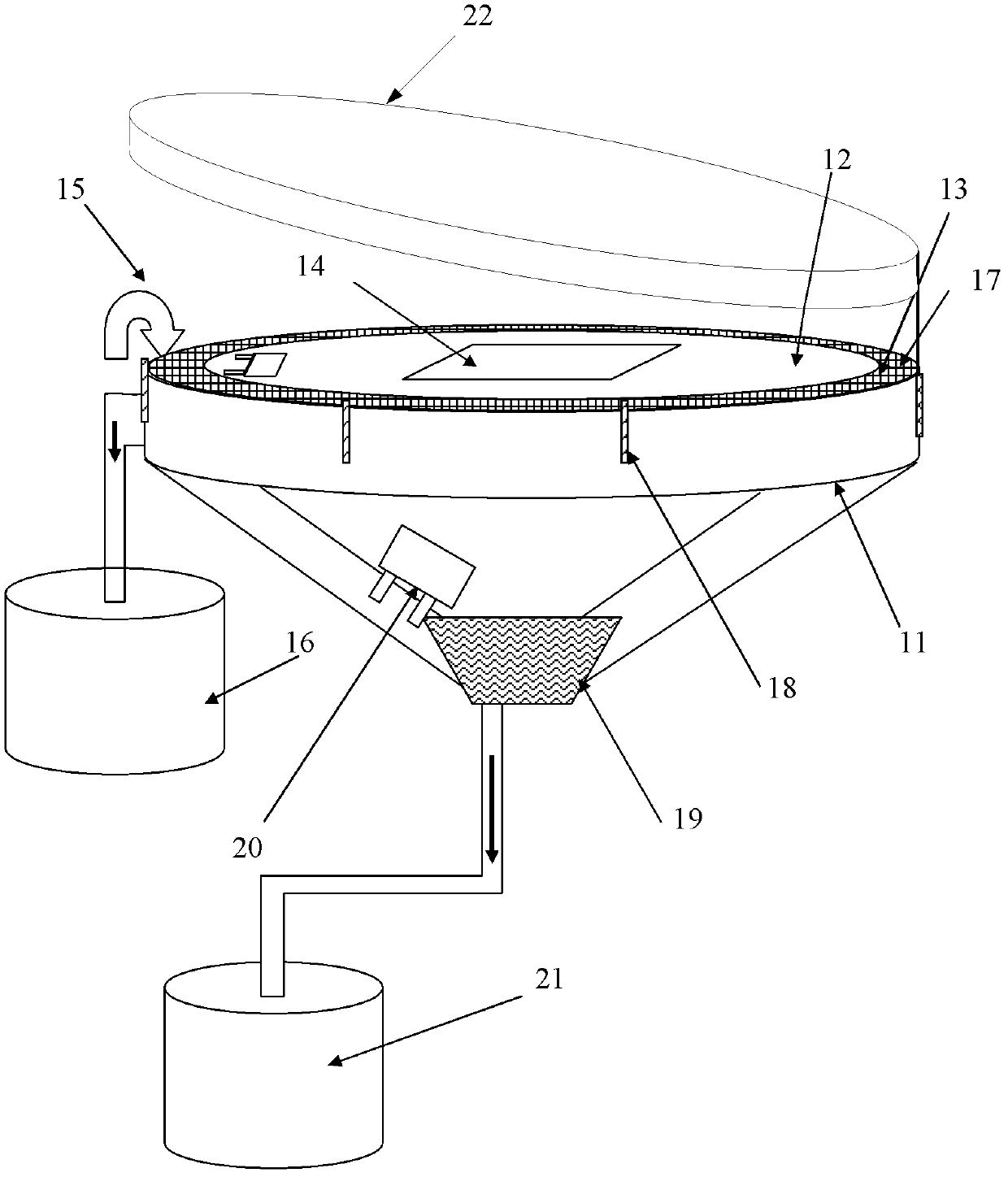

[0036] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

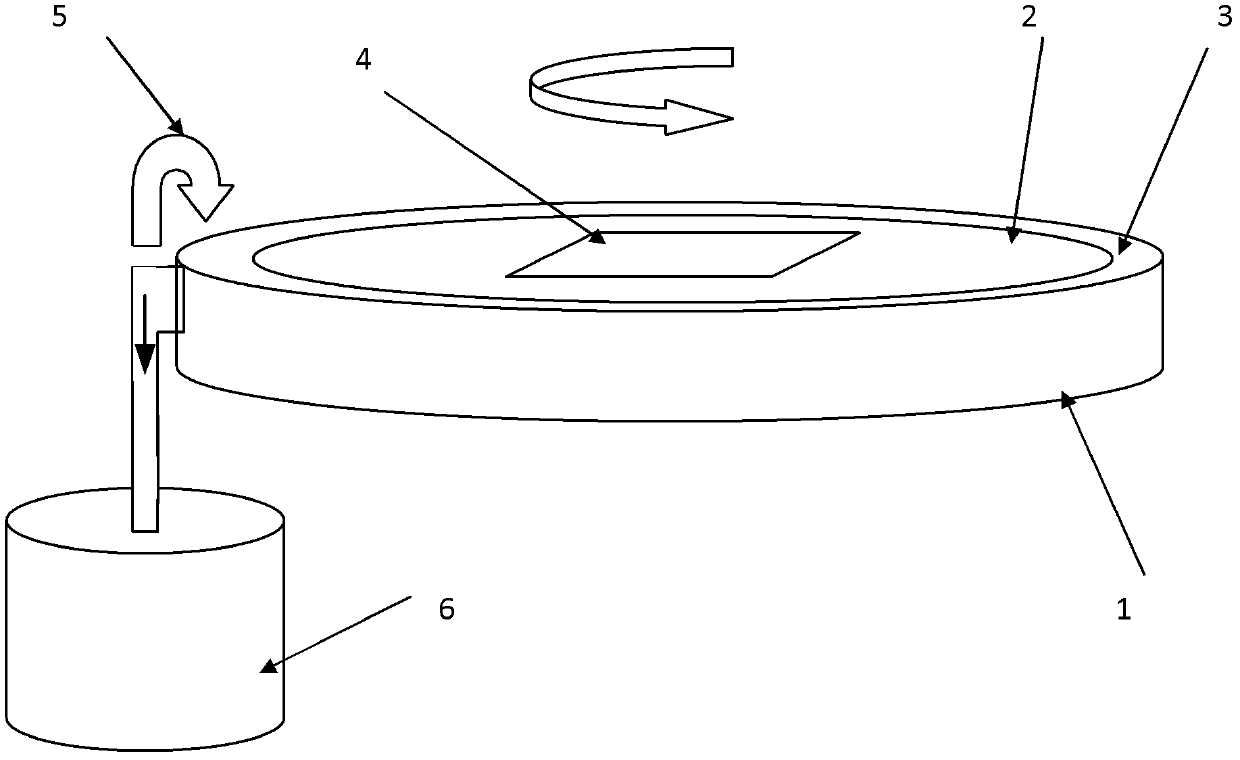

[0037] The embodiments of the present invention aim at the problem that a large amount of discharged photoresist cannot be recycled in the photolithography process of manufacturing color filter substrates and array substrates in the prior art, and provide a photoresist recycling system, which can The flung photoresist is recycled.

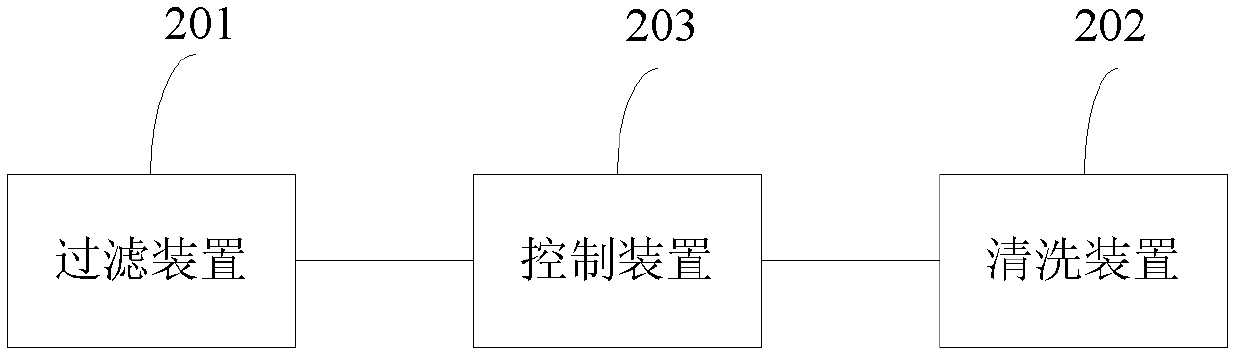

[0038] figure 2 It is a device composition diagram of a photoresist recovery system according to an embodiment of the present invention. This embodiment is applied to the photolithography process of color filter substrates and array substrates, including a substrate chassis and its upper cover, a substrate rotating disk located on the substrate chassis, The substrate card slot on the substrate rotating disk is used to place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com