Three-dimensional reconstruction method for damaged corrosive pitting topography of metal panel

A metal plate, three-dimensional reconstruction technology, used in 3D modeling, image data processing, instruments, etc., can solve the problems of low efficiency of computer programs for pit depth measurement errors, large surface area errors, etc., to change resolution and improve work. Efficiency, Scan Input Simple Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

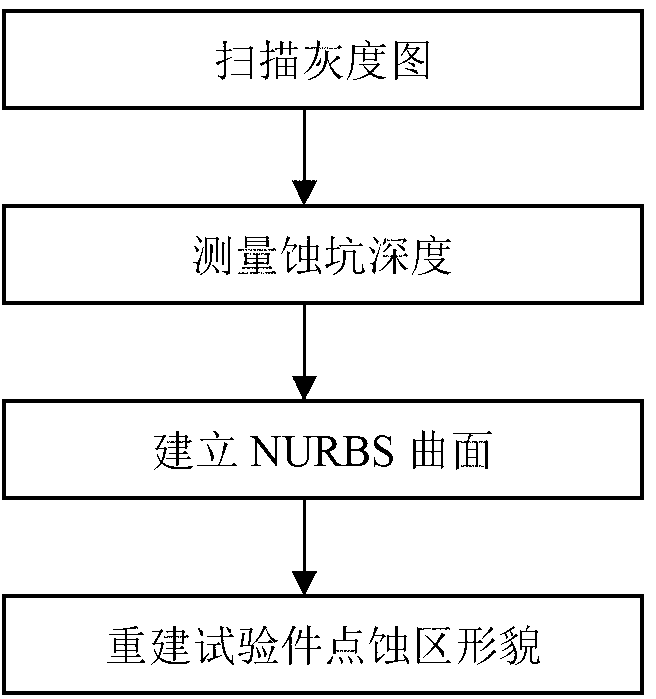

[0018] The present invention comprises the following steps:

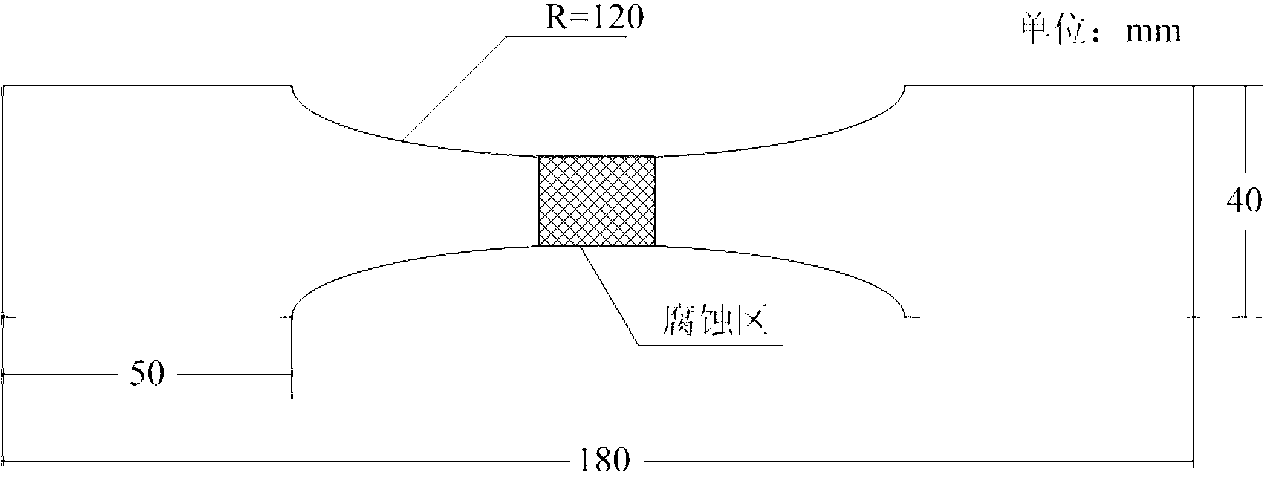

[0019] Step 1: Place the aluminum alloy plate after pitting on a flat scanner, start scanning, and scan the surface morphology of pitting pits into a 256-level grayscale image.

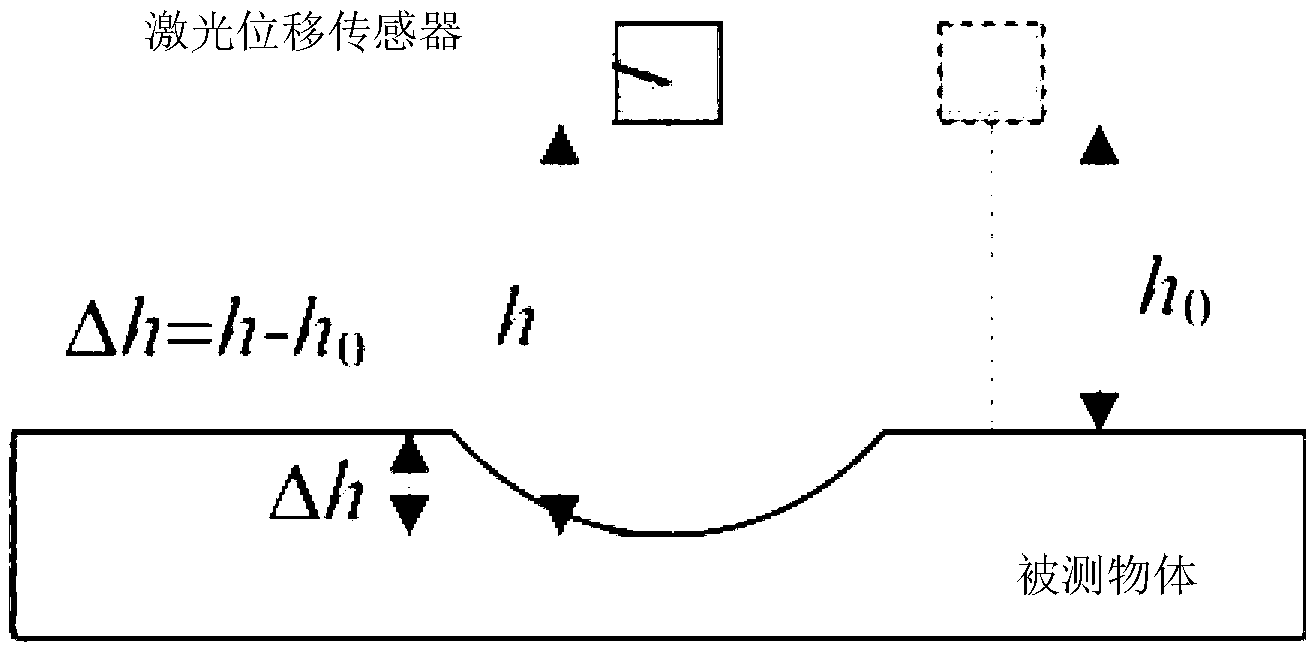

[0020] Step 2: Measure the depth of all pits in the corrosion area by using a laser displacement sensor, and calculate the average value of pit depths.

[0021] The depth value of the pitting pit is on the order of 10 2 μm, which requires the measurement equipment to have high precision, and the laser displacement sensor can meet this requirement. The laser displacement sensor is a triangulation measurement system using CCD (Charge Coupled Device, charge coupled device system), and its biggest advantage is non-contact measurement. The laser transmitter sends visible red laser light to the surface of the measured object through the lens, and the laser reflected by the object passes through the receiver lens and is received by the internal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com