Granulators for the production of granules

A granulator and granule technology, which is applied in the direction of material forming presses, presses, manufacturing tools, etc., can solve the problems of time-consuming, high cost, and limitation of the perimeter of the granulator.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

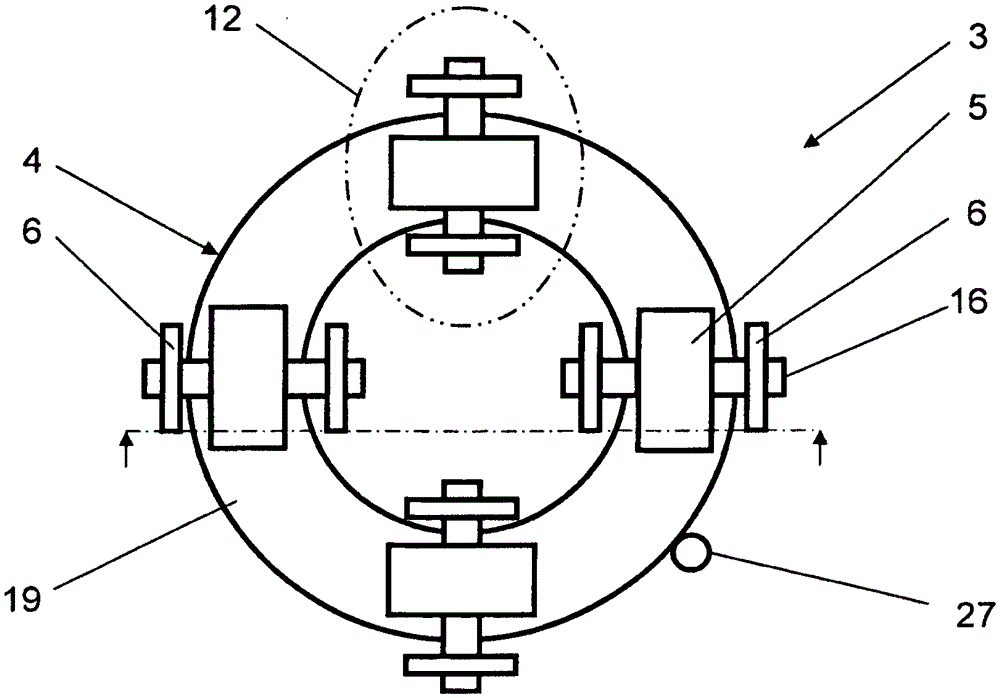

[0041] exist figure 1 A granulator 3 with four compacting devices 12 is shown in a preferred exemplary embodiment. However, depending in part on the inner or outer diameter of the mould, a plurality of compacting devices 12 may also be provided within the pelletizer 3 . In this preferred exemplary embodiment, the mold 4 with rolling surfaces 19 for the rollers 5 is mounted so that it is movable within the hold-down device 12 and is driven by at least one motor (not shown) to perform rolling around the mold 4. Circular motion of the axis. An optional motor for driving the rollers 5 within the hold-down device 12 is not shown.

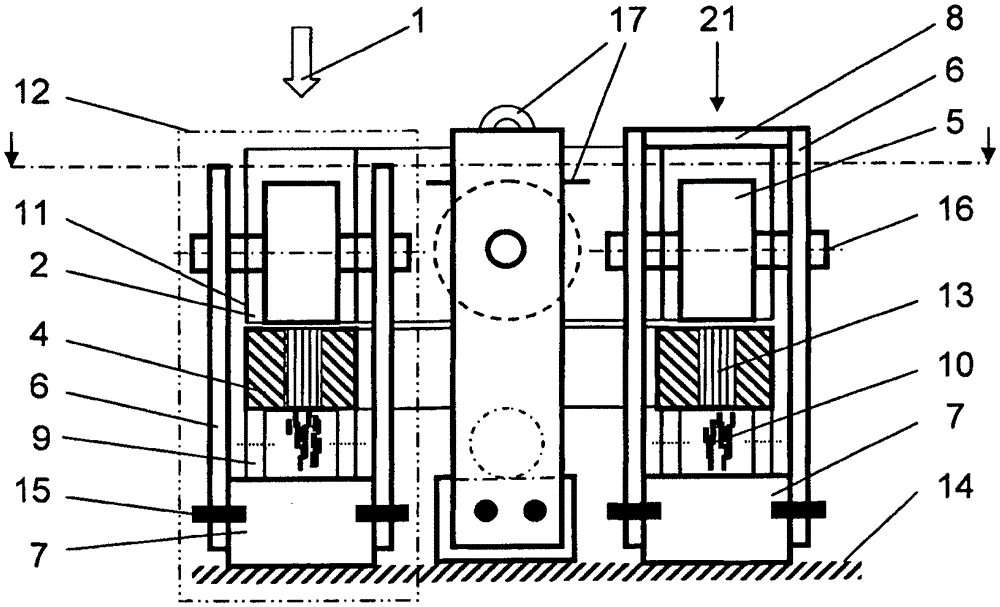

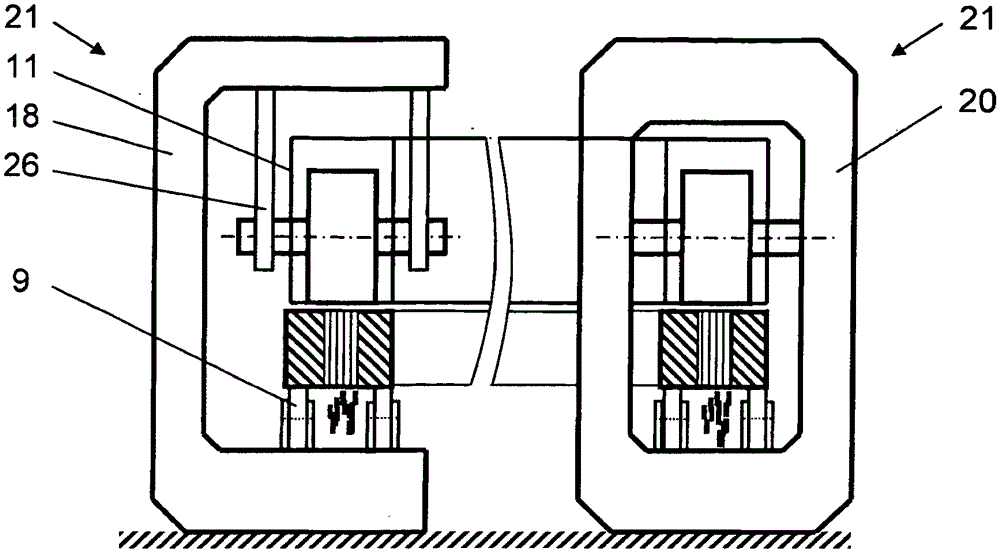

[0042] figure 2 based on figure 1 The sectional view of shows the granulator 3 on the base 14. In the schematic sectional view, a compacting frame 21 with a multi-component compacting frame consisting of at least one lower beam 7 and two pulling brackets 6 is provided, and the rollers 5 The shaft 16 mounted in the pulling bracket is kept movable by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com