Sunlight greenhouse solar photovoltaic power generation utilization device and method

A solar photovoltaic and solar greenhouse technology, applied in the field of greenhouse solar energy utilization, can solve the problems of waste of solar energy resources, reduce utilization efficiency, block light, etc., achieve strong flexibility and adaptability, improve economic benefits, and improve utilization rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

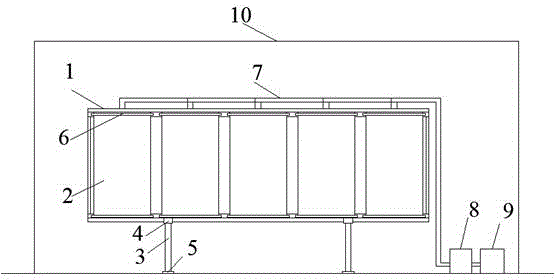

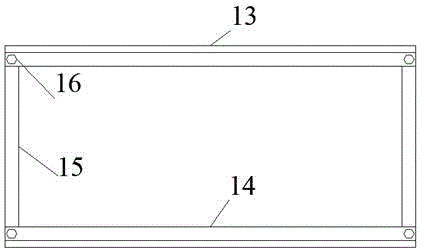

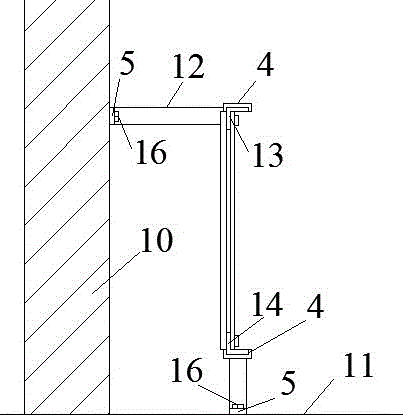

[0018] Such as Figure 1-2 As shown, the device of the present invention is installed inside the solar greenhouse, and the installation position is close to the vertical surface 10 of the rear vertical wall of the solar greenhouse. A plurality of solar photovoltaic power generation glasses or films 2 are arranged and fixedly placed on the fixed frame 1 at intervals, and the plurality of solar photovoltaic power generation glasses or films 2 are parallel to the vertical surface 10 of the rear vertical wall of the greenhouse. Solar photovoltaic power generation glass refers to the photovoltaic power generation glass covered with glass on the upper and lower surfaces of amorphous silicon, single crystal silicon or polycrystalline silicon solar cells. Corrosion; solar photovoltaic film also refers to the photovoltaic film covered with plastic film on the upper and lower surfaces of solar cells.

[0019] A positioning fixture 6 is installed at the corresponding position where each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com