Grain winnowing and stone and impurity removing separator

A separator and air separation technology, used in solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc., can solve the problems of simple structure, small processing capacity, complex structure, etc., and achieve the scope of material cleaning. Large, reduce power consumption, good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

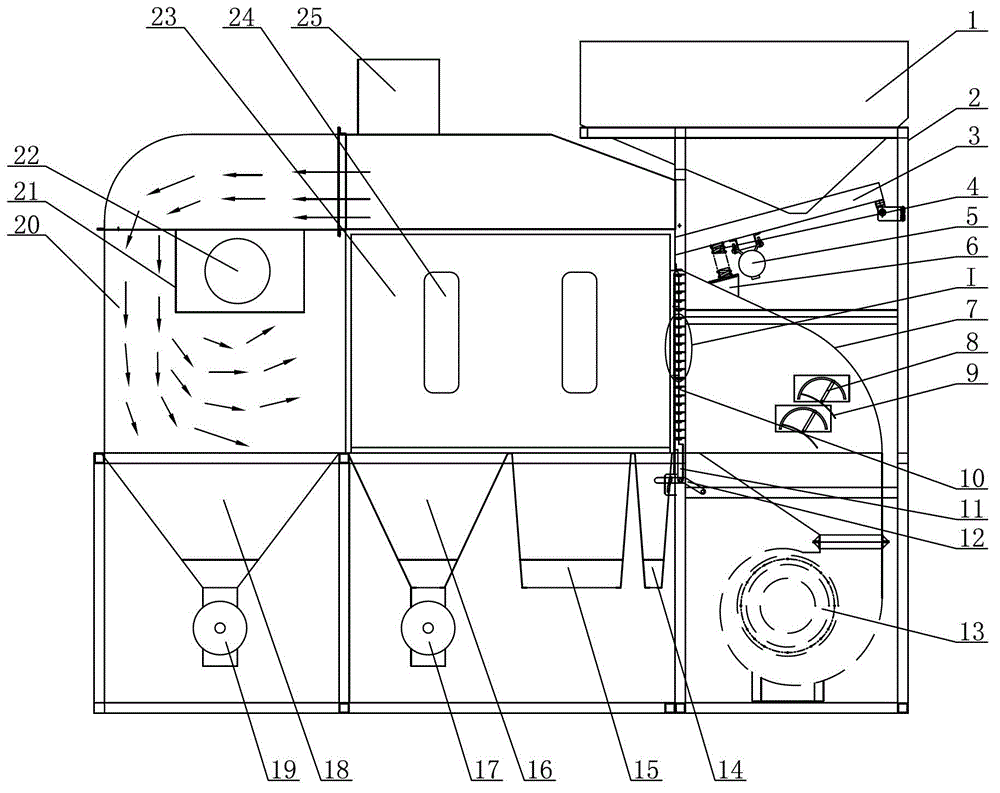

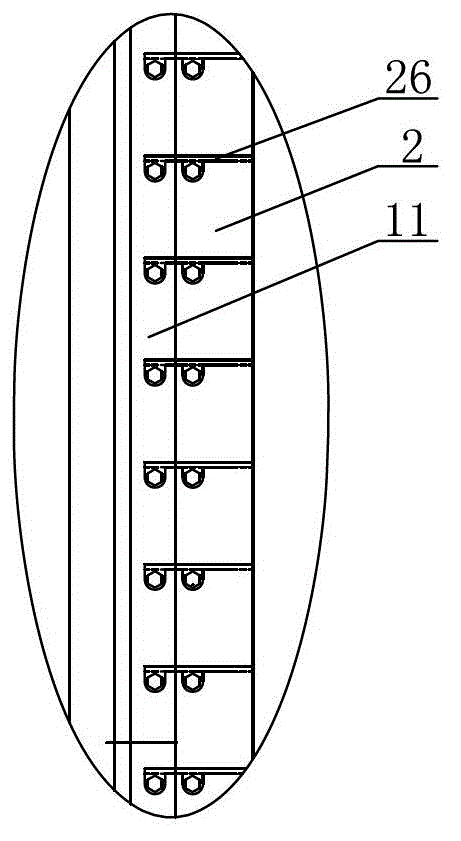

[0018] Such as figure 1 , 2 As shown, the grain air separation destoner and impurity removal separator includes a frame 2, an air supply system and a storage box 1 installed on the frame 2, and an air separation separation box 23, and the outlet of the storage box 1 is provided below. There is a vibrating feeding plate 3 inclined downward, a vibrating motor 5 is installed at the bottom of the vibrating feeding plate 3, the top of the vibrating feeding plate 3 is hinged on the frame 2, the bottom of the lower end of the blanking end is connected with a compression spring 4, and the compression spring 4 Installed on the frame by the spring seat 6, the blanking end of the vibrating feeding plate 3 is facing the inlet of the winnowing separation box 23, and the air supply system includes the blower fan 13 and the air supply channel 7, and the air outlet of the air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com