Method and device for realizing direct extrusion casting by utilizing closed mould pouring

A squeeze casting, direct technology, applied in the field of direct squeeze casting, can solve the problems of long time consumption, difficulty in quality assurance, impact on mold life, etc., to reduce oxidation and suction, large extrusion area, and extrusion direct effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

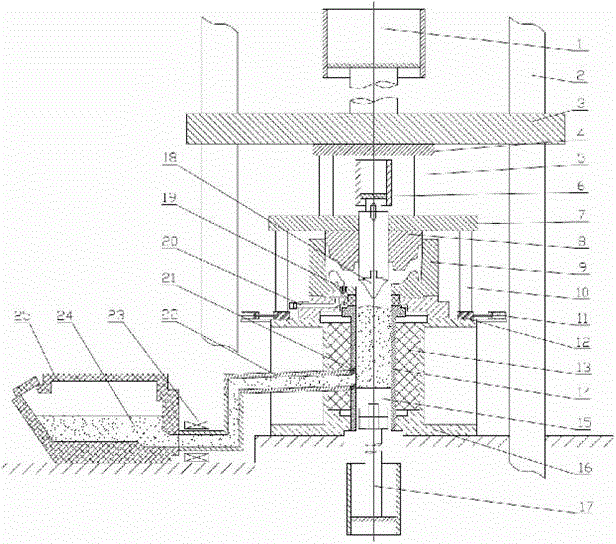

[0031] The present invention will be further described in detail through the following examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

[0032]The casting machine used in this embodiment is a 16000KN vertical casting machine (model LY-1600), and the conveying system 23 adopts an electromagnetic pump (model EMPS-LC). You can also choose to use a pneumatic conveying system or a mechanical pump according to actual working conditions. Piston feeding system.

[0033] The device that realizes the method of the present invention such as figure 1 As shown, it consists of a punch connecting plate 4, a punch connecting column 5, a central hydraulic cylinder 6, a punch seat 7, a punch 8, a die 9, a punch limit column 10, a pad side hydraulic cylinder 11, a punch Die limit pad 12, barrel insulation layer 13, barrel 14, pressure head 15, mold base 16, diverter cone 18, exhaust plug 19, air pipe 20, material mouth sleeve 21, materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com